Selective Catalytic Reduction (SCR) reduces nitrogen oxide (NOx) emissions by injecting a urea-based solution into exhaust gases, converting harmful pollutants into harmless nitrogen and water. Exhaust Gas Recirculation (EGR) lowers NOx emissions by recirculating a portion of the engine's exhaust back into the intake, reducing combustion temperatures and limiting NOx formation. SCR generally achieves higher NOx reduction efficiency than EGR, especially in heavy-duty diesel engines, making it a preferred technology for meeting stringent emission standards.

Table of Comparison

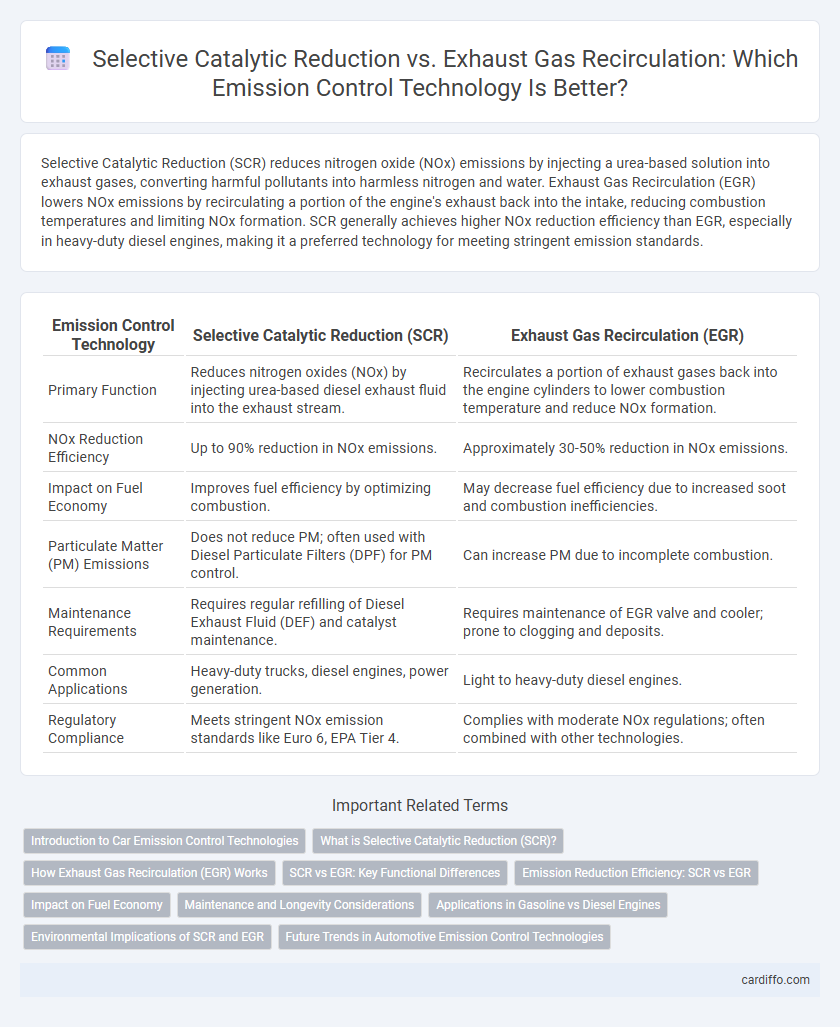

| Emission Control Technology | Selective Catalytic Reduction (SCR) | Exhaust Gas Recirculation (EGR) |

|---|---|---|

| Primary Function | Reduces nitrogen oxides (NOx) by injecting urea-based diesel exhaust fluid into the exhaust stream. | Recirculates a portion of exhaust gases back into the engine cylinders to lower combustion temperature and reduce NOx formation. |

| NOx Reduction Efficiency | Up to 90% reduction in NOx emissions. | Approximately 30-50% reduction in NOx emissions. |

| Impact on Fuel Economy | Improves fuel efficiency by optimizing combustion. | May decrease fuel efficiency due to increased soot and combustion inefficiencies. |

| Particulate Matter (PM) Emissions | Does not reduce PM; often used with Diesel Particulate Filters (DPF) for PM control. | Can increase PM due to incomplete combustion. |

| Maintenance Requirements | Requires regular refilling of Diesel Exhaust Fluid (DEF) and catalyst maintenance. | Requires maintenance of EGR valve and cooler; prone to clogging and deposits. |

| Common Applications | Heavy-duty trucks, diesel engines, power generation. | Light to heavy-duty diesel engines. |

| Regulatory Compliance | Meets stringent NOx emission standards like Euro 6, EPA Tier 4. | Complies with moderate NOx regulations; often combined with other technologies. |

Introduction to Car Emission Control Technologies

Selective Catalytic Reduction (SCR) and Exhaust Gas Recirculation (EGR) are key car emission control technologies designed to reduce harmful nitrogen oxides (NOx) from diesel and gasoline engines. SCR uses a urea-based solution to convert NOx into nitrogen and water vapor, enhancing emission reduction efficiency, especially in heavy-duty vehicles. EGR recirculates a portion of exhaust gases back into the engine intake to lower combustion temperatures and reduce NOx formation, primarily used in light-duty engines for improving fuel economy and emissions compliance.

What is Selective Catalytic Reduction (SCR)?

Selective Catalytic Reduction (SCR) is an advanced emission control technology that reduces nitrogen oxides (NOx) from diesel engine exhaust by injecting a urea-based reductant into the exhaust stream. This chemical reaction converts harmful NOx gases into harmless nitrogen and water vapor, significantly lowering air pollution. SCR systems are highly effective in meeting stringent environmental regulations and improving air quality in heavy-duty vehicles and industrial applications.

How Exhaust Gas Recirculation (EGR) Works

Exhaust Gas Recirculation (EGR) reduces nitrogen oxide (NOx) emissions by recirculating a portion of the engine's exhaust gases back into the intake manifold, lowering combustion temperatures. This dilution decreases oxygen concentration in the combustion chamber, effectively suppressing the formation of NOx during combustion. EGR systems vary in design, including high-pressure and low-pressure configurations, optimized for different engine types to improve emission control and fuel efficiency.

SCR vs EGR: Key Functional Differences

Selective Catalytic Reduction (SCR) reduces nitrogen oxide (NOx) emissions by injecting urea-based reductant into the exhaust stream, converting NOx into nitrogen and water through a catalytic reaction. Exhaust Gas Recirculation (EGR) lowers combustion temperatures by recirculating a portion of exhaust gases back into the engine intake, which decreases NOx formation at the source. SCR is typically more effective at higher loads and achieves greater NOx reduction efficiency, while EGR is integrated into the engine cycle to reduce NOx generation before the exhaust phase.

Emission Reduction Efficiency: SCR vs EGR

Selective Catalytic Reduction (SCR) systems typically achieve higher emission reduction efficiency by converting up to 90% of nitrogen oxides (NOx) into harmless nitrogen and water through a chemical reaction with injected urea. Exhaust Gas Recirculation (EGR) lowers NOx emissions by recirculating a portion of exhaust gases back into the combustion chamber, reducing peak combustion temperatures but often with less effectiveness, achieving around 30-50% NOx reduction. SCR outperforms EGR in reducing NOx emissions, especially in heavy-duty diesel engines, making it a preferred technology to meet stringent emission standards like Euro 6 and EPA Tier 4.

Impact on Fuel Economy

Selective Catalytic Reduction (SCR) systems typically have a minimal impact on fuel economy because they treat NOx emissions after combustion, allowing engines to operate at optimal fuel efficiency. Exhaust Gas Recirculation (EGR) reduces NOx formation during combustion but often decreases fuel economy by lowering combustion temperature and increasing pumping losses. Studies indicate SCR-equipped engines can achieve fuel economy improvements of up to 5% compared to EGR-only systems.

Maintenance and Longevity Considerations

Selective Catalytic Reduction (SCR) systems require regular replenishment of urea-based reductant and periodic catalyst inspection to maintain optimal performance, but the catalyst longevity typically spans over 100,000 miles with proper care. Exhaust Gas Recirculation (EGR) systems demand frequent cleaning of carbon deposits and monitoring of cooler integrity, as soot buildup can reduce efficiency and increase maintenance frequency. SCR systems generally offer longer component life and lower maintenance intervals compared to EGR, which faces higher wear due to exposure to particulate matter and thermal stress.

Applications in Gasoline vs Diesel Engines

Selective Catalytic Reduction (SCR) systems are primarily applied in diesel engines to reduce nitrogen oxide (NOx) emissions by injecting a urea-based solution into the exhaust stream, effectively converting NOx into nitrogen and water. Exhaust Gas Recirculation (EGR) is widely utilized in both gasoline and diesel engines, but its configurations differ; gasoline engines typically employ low-pressure EGR to reduce combustion temperatures and NOx, while diesel engines favor high-pressure EGR to recirculate exhaust gases, decreasing oxygen concentration and NOx formation. SCR shows higher efficacy in heavy-duty diesel applications due to stringent emission standards, whereas EGR remains essential in light-duty gasoline engines for optimizing combustion and meeting emission regulations.

Environmental Implications of SCR and EGR

Selective Catalytic Reduction (SCR) effectively reduces NOx emissions by converting them into harmless nitrogen and water using a urea-based reagent, resulting in significant improvements in air quality and compliance with stringent emission standards. Exhaust Gas Recirculation (EGR) lowers combustion temperatures by recirculating a portion of exhaust gases back into the engine, which reduces NOx formation but can lead to increased particulate matter and potential fuel efficiency losses. SCR systems typically offer greater environmental benefits by achieving higher NOx reduction rates with less impact on engine performance and particulate emissions compared to EGR.

Future Trends in Automotive Emission Control Technologies

Selective Catalytic Reduction (SCR) and Exhaust Gas Recirculation (EGR) remain pivotal in reducing nitrogen oxides (NOx) emissions from diesel engines, with SCR offering superior NOx reduction efficiency by converting pollutants into nitrogen and water using urea-based reductants. Future trends emphasize integrating SCR with advanced aftertreatment systems and hybrid EGR strategies to optimize fuel efficiency and minimize particulate matter while meeting stringent Euro 7 and EPA Tier 3 emission standards. Emerging technologies such as electrically heated catalysts and machine learning-driven emission control systems are expected to enhance real-time adaptation and durability of SCR and EGR components in next-generation vehicles.

Selective Catalytic Reduction vs Exhaust Gas Recirculation Infographic

cardiffo.com

cardiffo.com