Oxidative catalysts primarily reduce carbon monoxide and hydrocarbons by converting them into carbon dioxide and water through oxidation reactions in emission control systems. Selective catalytic reduction (SCR) targets nitrogen oxides (NOx) emissions by injecting a reductant like ammonia or urea, which reacts with NOx to form nitrogen and water. SCR systems achieve higher NOx reduction efficiency compared to oxidative catalysts, making them essential for meeting stringent emission standards in diesel engines.

Table of Comparison

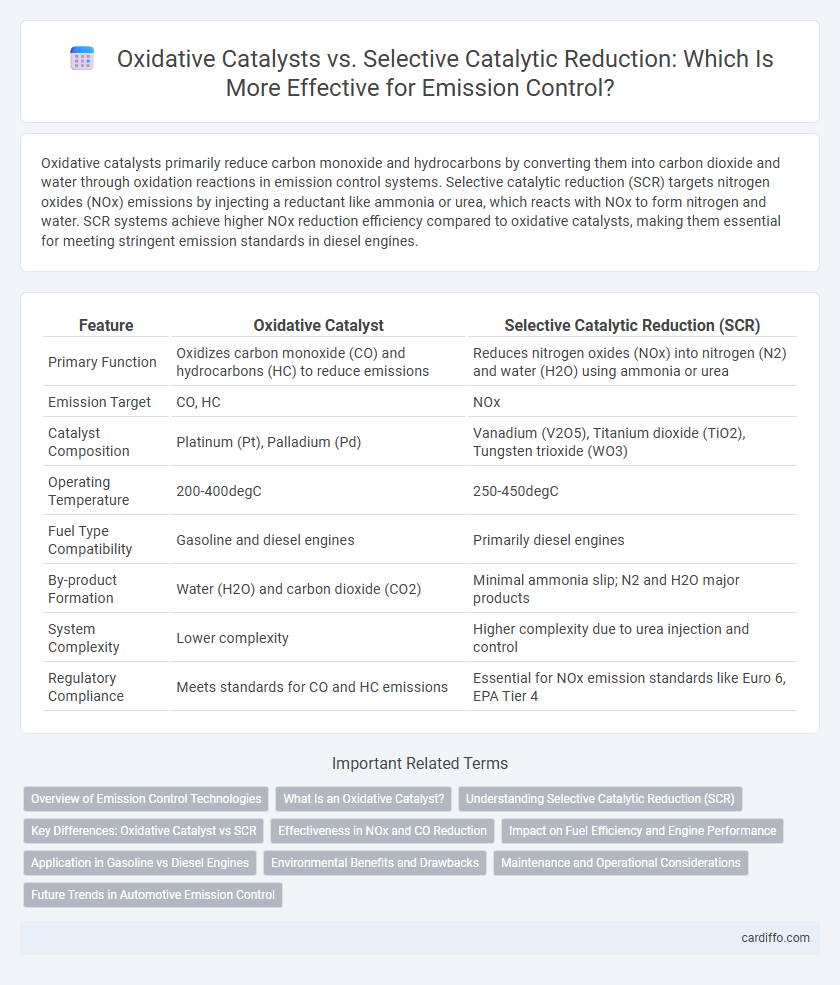

| Feature | Oxidative Catalyst | Selective Catalytic Reduction (SCR) |

|---|---|---|

| Primary Function | Oxidizes carbon monoxide (CO) and hydrocarbons (HC) to reduce emissions | Reduces nitrogen oxides (NOx) into nitrogen (N2) and water (H2O) using ammonia or urea |

| Emission Target | CO, HC | NOx |

| Catalyst Composition | Platinum (Pt), Palladium (Pd) | Vanadium (V2O5), Titanium dioxide (TiO2), Tungsten trioxide (WO3) |

| Operating Temperature | 200-400degC | 250-450degC |

| Fuel Type Compatibility | Gasoline and diesel engines | Primarily diesel engines |

| By-product Formation | Water (H2O) and carbon dioxide (CO2) | Minimal ammonia slip; N2 and H2O major products |

| System Complexity | Lower complexity | Higher complexity due to urea injection and control |

| Regulatory Compliance | Meets standards for CO and HC emissions | Essential for NOx emission standards like Euro 6, EPA Tier 4 |

Overview of Emission Control Technologies

Oxidative catalysts reduce harmful emissions by converting carbon monoxide (CO) and hydrocarbons (HC) into carbon dioxide (CO2) and water through oxidation processes, primarily effective in gasoline engines. Selective Catalytic Reduction (SCR) targets nitrogen oxides (NOx) in diesel exhaust by injecting a urea-based reductant, transforming NOx into nitrogen (N2) and water, significantly lowering NOx levels. Both technologies play critical roles in meeting stringent emission standards, with oxidative catalysts focusing on HC and CO control, while SCR excels in NOx reduction for heavy-duty diesel applications.

What Is an Oxidative Catalyst?

An oxidative catalyst is a device used in emission control systems to convert harmful gases such as carbon monoxide (CO) and unburned hydrocarbons (HC) into less harmful carbon dioxide (CO2) and water (H2O) through oxidation reactions. It operates at high temperatures to promote the chemical transformation of pollutants, improving air quality by reducing toxic exhaust emissions. Unlike selective catalytic reduction (SCR), which targets nitrogen oxides (NOx) reduction, oxidative catalysts specifically focus on diminishing CO and HC levels in automotive and industrial exhaust streams.

Understanding Selective Catalytic Reduction (SCR)

Selective Catalytic Reduction (SCR) is an advanced emission control technology designed to reduce nitrogen oxides (NOx) from exhaust gases using a catalyst and a reductant, typically ammonia or urea. SCR systems convert NOx into harmless nitrogen and water by facilitating a chemical reaction in the presence of a catalyst, achieving reduction efficiencies up to 90%. Unlike oxidative catalysts, which primarily oxidize carbon monoxide and hydrocarbons, SCR specifically targets NOx, making it highly effective for diesel engines and large industrial sources.

Key Differences: Oxidative Catalyst vs SCR

Oxidative catalysts primarily convert carbon monoxide (CO) and hydrocarbons (HC) into carbon dioxide (CO2) and water (H2O) through oxidation reactions, effectively reducing these pollutants in gasoline engines. Selective Catalytic Reduction (SCR) systems target nitrogen oxides (NOx) emissions in diesel engines by injecting a urea-based reductant, converting NOx into nitrogen (N2) and water, thus achieving significant NOx reduction. The key difference lies in the pollutant type addressed and the chemical process: oxidative catalysts focus on oxidizing CO and HC, while SCR reduces NOx via a selective reduction reaction.

Effectiveness in NOx and CO Reduction

Oxidative catalysts effectively reduce carbon monoxide (CO) by converting it into carbon dioxide (CO2), but their efficiency in nitrogen oxides (NOx) reduction is limited due to their primary focus on oxidation reactions. Selective Catalytic Reduction (SCR) systems target NOx emissions specifically by using ammonia or urea as reductants to convert NOx into nitrogen (N2) and water vapor (H2O), achieving up to 90% NOx reduction efficiency. While SCR excels in NOx abatement, it typically requires a dedicated reductant and catalyst system, whereas oxidative catalysts provide broader CO reduction but less NOx control.

Impact on Fuel Efficiency and Engine Performance

Oxidative catalysts enhance fuel efficiency by promoting the oxidation of carbon monoxide and hydrocarbons with minimal impact on engine performance, maintaining stable combustion processes. Selective catalytic reduction (SCR) significantly reduces nitrogen oxide emissions through the injection of a reductant like urea, which can slightly affect engine load and fuel consumption due to additional system requirements. Optimizing these technologies balances stringent emission controls with maintaining optimal engine power and fuel economy in modern diesel engines.

Application in Gasoline vs Diesel Engines

Oxidative catalysts are primarily used in gasoline engines to convert carbon monoxide and hydrocarbons into carbon dioxide and water through oxidation, improving air quality by reducing harmful emissions. Selective catalytic reduction (SCR) systems are predominantly applied in diesel engines, utilizing ammonia-based reagents to reduce nitrogen oxide (NOx) emissions into nitrogen and water, effectively meeting stringent emission standards. Each technology is optimized for the distinct combustion characteristics and emission profiles of gasoline and diesel engines, ensuring compliance with environmental regulations.

Environmental Benefits and Drawbacks

Oxidative catalysts reduce carbon monoxide (CO) and unburned hydrocarbons (HC) by converting them into carbon dioxide (CO2) and water, thereby lowering smog formation but generating higher CO2 emissions. Selective catalytic reduction (SCR) effectively decreases nitrogen oxides (NOx) by injecting ammonia or urea into exhaust gases, significantly mitigating acid rain and ozone depletion but requiring complex infrastructure and handling of hazardous reagents. The environmental trade-offs between increased greenhouse gas output from oxidative catalysts and the NOx reduction efficiency of SCR systems are critical in determining optimal emission control strategies.

Maintenance and Operational Considerations

Oxidative catalysts require regular maintenance to prevent catalyst poisoning and ensure optimal oxidation efficiency, often necessitating periodic inspection of temperature sensors and replacement of contaminated catalyst substrates. Selective catalytic reduction (SCR) systems demand precise dosing of reductants like ammonia or urea and continuous monitoring of catalyst activity to avoid deactivation, with maintenance involving injector cleaning and control system calibration. Operational considerations for SCR include managing reagent supply logistics and ensuring low ammonia slip, while oxidative catalysts generally have simpler operational protocols but may face higher sensitivity to fuel sulfur content.

Future Trends in Automotive Emission Control

Oxidative catalysts, commonly used for reducing carbon monoxide and hydrocarbons, face limitations in controlling nitrogen oxides (NOx) in diesel engines, prompting a shift toward selective catalytic reduction (SCR) systems that use ammonia or urea-based reductants to convert NOx into nitrogen and water. Future trends in automotive emission control highlight the integration of SCR with advanced sensor technologies and real-time diagnostics to optimize catalyst performance and reduce emissions under varying driving conditions. Emerging developments also focus on hybrid catalyst systems combining oxidative catalysts with SCR for enhanced multi-pollutant mitigation and improved fuel efficiency compliance with stringent Euro 7 and EPA Tier 3 standards.

Oxidative catalyst vs selective catalytic reduction Infographic

cardiffo.com

cardiffo.com