Direct injection engines typically produce higher particulate emissions due to precise fuel delivery directly into the combustion chamber, improving fuel efficiency but increasing soot formation. Port fuel injection engines spray fuel into the intake manifold, resulting in better air-fuel mixing and lower particulate emissions but often higher carbon monoxide and hydrocarbon outputs. Advances in emission control technologies aim to balance these trade-offs to meet stringent environmental regulations.

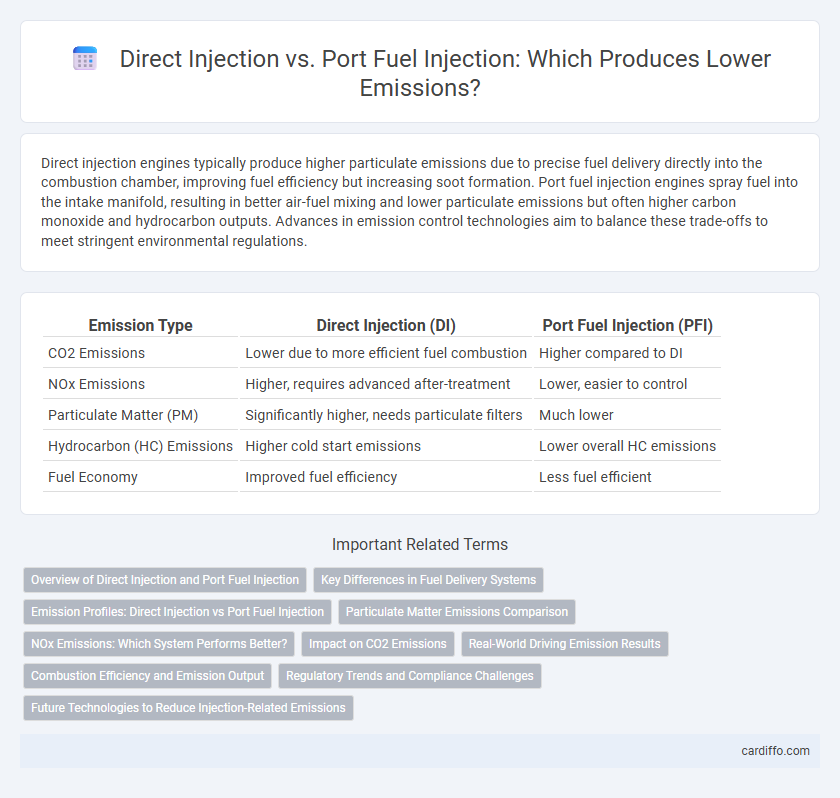

Table of Comparison

| Emission Type | Direct Injection (DI) | Port Fuel Injection (PFI) |

|---|---|---|

| CO2 Emissions | Lower due to more efficient fuel combustion | Higher compared to DI |

| NOx Emissions | Higher, requires advanced after-treatment | Lower, easier to control |

| Particulate Matter (PM) | Significantly higher, needs particulate filters | Much lower |

| Hydrocarbon (HC) Emissions | Higher cold start emissions | Lower overall HC emissions |

| Fuel Economy | Improved fuel efficiency | Less fuel efficient |

Overview of Direct Injection and Port Fuel Injection

Direct Injection (DI) delivers fuel directly into the combustion chamber, enhancing fuel atomization and combustion efficiency, resulting in lower carbon dioxide (CO2) emissions but potentially higher particulate matter (PM) and nitrogen oxides (NOx) emissions. Port Fuel Injection (PFI) sprays fuel into the intake manifold, promoting better air-fuel mixing and generally producing fewer PM emissions but higher CO2 compared to DI. Emission control strategies often combine both systems to optimize performance and minimize overall pollutant output.

Key Differences in Fuel Delivery Systems

Direct injection systems spray fuel directly into the combustion chamber, resulting in more precise fuel metering and improved combustion efficiency, which reduces CO2 emissions but can increase particulate matter and NOx levels. Port fuel injection delivers fuel into the intake manifold, promoting better fuel-air mixing before entering the cylinder, leading to lower particulate emissions but generally higher CO2 outputs compared to direct injection. Differences in spray timing, atomization quality, and combustion characteristics between these systems significantly impact the overall emission profiles and environmental performance of engines.

Emission Profiles: Direct Injection vs Port Fuel Injection

Direct injection engines produce higher particulate matter and nitrogen oxide emissions due to precise fuel delivery directly into the combustion chamber, enhancing combustion efficiency but increasing soot formation. Port fuel injection systems emit lower particulate matter as fuel is mixed with air before entering the cylinder, promoting more complete combustion and reduced soot levels. However, port fuel injection typically results in higher carbon monoxide and hydrocarbon emissions compared to direct injection.

Particulate Matter Emissions Comparison

Direct injection (DI) engines generally produce higher particulate matter (PM) emissions compared to port fuel injection (PFI) systems due to the localized fuel spray and incomplete combustion. Studies show DI engines emit up to 10 times more PM particles, particularly ultrafine particles, which contribute significantly to air pollution and health risks. Advanced emission controls like gasoline particulate filters (GPFs) are critical in reducing PM emissions from DI engines to meet stringent regulatory standards.

NOx Emissions: Which System Performs Better?

Direct injection (DI) engines typically produce higher NOx emissions compared to port fuel injection (PFI) due to leaner combustion and higher combustion temperatures. Port fuel injection systems mix fuel with air before entering the combustion chamber, resulting in cooler combustion and lower NOx levels. Advanced emission control technologies such as selective catalytic reduction (SCR) and exhaust gas recirculation (EGR) are often required in DI engines to mitigate these elevated NOx emissions.

Impact on CO2 Emissions

Direct injection engines typically produce lower CO2 emissions compared to port fuel injection systems due to improved fuel atomization and more precise combustion control. This enhanced efficiency allows for better fuel economy, directly reducing carbon dioxide output per mile driven. However, direct injection engines may emit higher particulate matter, necessitating advanced after-treatment technologies to meet overall emission standards.

Real-World Driving Emission Results

Direct injection engines generally produce lower carbon dioxide (CO2) emissions during real-world driving compared to port fuel injection systems due to improved fuel atomization and combustion efficiency. However, direct injection tends to emit higher levels of particulate matter (PM) and nitrogen oxides (NOx) under real-driving conditions, contributing to urban air pollution concerns. Port fuel injection engines typically demonstrate lower particulate emissions but higher CO2 output, making the trade-off between greenhouse gases and local pollutants critical in emission regulation strategies.

Combustion Efficiency and Emission Output

Direct injection engines improve combustion efficiency by delivering fuel directly into the combustion chamber, resulting in a more precise air-fuel mixture and reduced unburned hydrocarbons. Port fuel injection systems mix fuel with air before entering the cylinder, which can lead to less efficient combustion and higher emissions of carbon monoxide and particulate matter. Despite lower PM emissions in port fuel injection, direct injection typically achieves better fuel economy and lower CO2 output due to enhanced combustion control.

Regulatory Trends and Compliance Challenges

Direct injection (DI) engines typically emit higher levels of particulate matter (PM) compared to port fuel injection (PFI) systems, posing significant challenges for meeting increasingly stringent regulatory emission standards such as Euro 7 and California's LEV III. Regulatory trends emphasize tighter limits on nitrogen oxides (NOx) and PM, driving innovations in particulate filter technologies and advanced after-treatment systems specifically designed for DI engines. Compliance challenges arise from the need to balance performance and fuel efficiency with emission controls, necessitating continuous optimization of injection strategies and engine calibration to satisfy global emission regulations.

Future Technologies to Reduce Injection-Related Emissions

Direct injection engines emit higher levels of particulate matter compared to port fuel injection systems due to fuel being injected directly into the combustion chamber. Future technologies such as advanced fuel atomization, high-precision multi-hole injectors, and low-temperature combustion strategies aim to significantly reduce these injection-related emissions. Integrating gasoline particulate filters (GPFs) and adopting hybrid fuel injection systems also contribute to lowering particulate and NOx emissions for cleaner combustion.

Direct injection vs Port fuel injection emissions Infographic

cardiffo.com

cardiffo.com