Catalytic converters (CAT) reduce harmful gases such as carbon monoxide, hydrocarbons, and nitrogen oxides by converting them into less toxic substances through chemical reactions. Diesel particulate filters (DPF) specifically target particulate matter by trapping and oxidizing soot particles from diesel exhaust. While CAT focuses on gas emissions, DPF effectively minimizes solid particulate pollutants, playing a crucial role in comprehensive emission control for diesel engines.

Table of Comparison

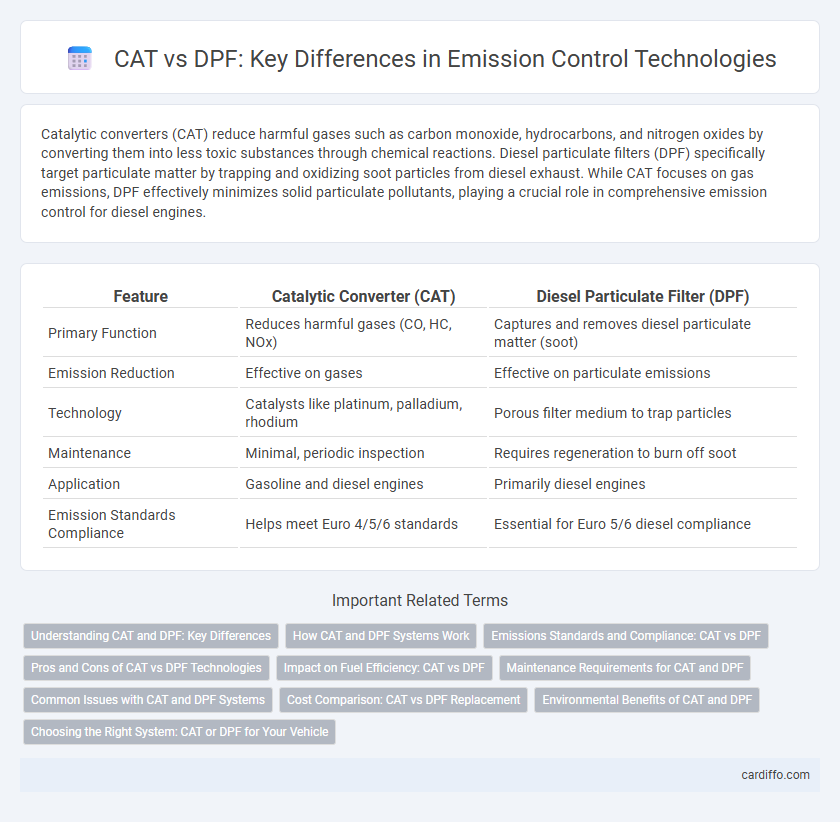

| Feature | Catalytic Converter (CAT) | Diesel Particulate Filter (DPF) |

|---|---|---|

| Primary Function | Reduces harmful gases (CO, HC, NOx) | Captures and removes diesel particulate matter (soot) |

| Emission Reduction | Effective on gases | Effective on particulate emissions |

| Technology | Catalysts like platinum, palladium, rhodium | Porous filter medium to trap particles |

| Maintenance | Minimal, periodic inspection | Requires regeneration to burn off soot |

| Application | Gasoline and diesel engines | Primarily diesel engines |

| Emission Standards Compliance | Helps meet Euro 4/5/6 standards | Essential for Euro 5/6 diesel compliance |

Understanding CAT and DPF: Key Differences

Catalytic Converters (CAT) primarily reduce harmful gases like carbon monoxide, hydrocarbons, and nitrogen oxides by converting them into less toxic substances. Diesel Particulate Filters (DPF) specifically target and capture particulate matter, such as soot, from diesel engine exhaust to prevent air pollution. Understanding these differences is crucial for optimizing emission control strategies in gasoline versus diesel engines.

How CAT and DPF Systems Work

Catalytic converters (CAT) reduce vehicle emissions by converting harmful gases like carbon monoxide, hydrocarbons, and nitrogen oxides into less harmful substances such as carbon dioxide, nitrogen, and water through chemical reactions on a catalyst surface. Diesel Particulate Filters (DPF) trap and remove particulate matter, specifically soot, by filtering exhaust gases and periodically burning off accumulated particles in a regeneration process to prevent clogging. Both systems work synergistically in diesel engines to lower overall emissions, with CAT targeting gaseous pollutants and DPF focusing on solid particulates.

Emissions Standards and Compliance: CAT vs DPF

Catalytic Converters (CAT) and Diesel Particulate Filters (DPF) play crucial roles in meeting stringent emissions standards by targeting different pollutants; CAT reduces harmful gases such as carbon monoxide and nitrogen oxides, while DPFs capture particulate matter from diesel engines. Compliance with regulations like Euro 6 and EPA Tier 4 depends on integrating both technologies to effectively control gaseous emissions and particulate matter, ensuring vehicles meet limits for NOx, CO, PM, and HC. Optimizing emissions control systems by combining CAT and DPF improves air quality, enhances engine performance, and supports adherence to evolving environmental policies worldwide.

Pros and Cons of CAT vs DPF Technologies

Catalytic Converters (CAT) effectively reduce harmful gases like carbon monoxide and hydrocarbons through catalytic reactions, offering low maintenance and durability but are less efficient in controlling particulate matter. Diesel Particulate Filters (DPF) excel at capturing and storing soot and particulates, significantly lowering particulate emissions but require periodic regeneration and can increase backpressure, impacting engine performance. Selecting CAT or DPF depends on emission control goals, with CAT favored for gas phase pollutants and DPF essential for particulate reduction in diesel engines.

Impact on Fuel Efficiency: CAT vs DPF

Catalytic Converters (CAT) generally have a lower impact on fuel efficiency compared to Diesel Particulate Filters (DPF) due to their less restrictive exhaust flow, allowing engines to operate with minimal back pressure. DPF systems can increase fuel consumption by 2-5% as they trap particulate matter and require periodic regeneration processes that consume extra fuel. Optimizing DPF regeneration intervals and using advanced engine management systems can help mitigate the negative impact on overall fuel efficiency.

Maintenance Requirements for CAT and DPF

CAT (Catalytic Converter) maintenance primarily involves periodic inspection and cleaning to prevent clogging and ensure efficient conversion of harmful gases, typically requiring less frequent servicing compared to DPF (Diesel Particulate Filter). DPF maintenance demands more rigorous attention, including regular regeneration cycles to burn off accumulated soot and occasional manual cleaning or replacement to maintain optimal performance and avoid engine issues. Neglecting proper DPF upkeep can lead to increased backpressure and fuel consumption, whereas CAT systems are generally more resilient with straightforward maintenance routines.

Common Issues with CAT and DPF Systems

Catalytic converters (CAT) commonly face issues like clogging, thermal degradation, and catalyst poisoning due to contaminants such as lead or sulfur. Diesel Particulate Filters (DPF) often suffer from blockage caused by soot accumulation and incomplete regeneration cycles, leading to increased backpressure and reduced engine efficiency. Both systems require regular maintenance and proper fuel quality to prevent malfunctions that increase harmful emissions.

Cost Comparison: CAT vs DPF Replacement

The cost comparison between Catalytic Converters (CAT) and Diesel Particulate Filters (DPF) shows that CAT replacement typically ranges from $500 to $2,500, depending on the vehicle model and part quality. In contrast, DPF replacement is often more expensive, averaging between $1,000 and $4,000 due to the complex design and advanced filtration technology. Maintenance frequency and the type of emission standards the vehicle must meet also influence the overall cost effectiveness of CAT versus DPF systems.

Environmental Benefits of CAT and DPF

Catalytic Converters (CAT) significantly reduce harmful emissions such as carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx) through chemical reactions that convert pollutants into less harmful gases like carbon dioxide and nitrogen. Diesel Particulate Filters (DPF) effectively trap and remove particulate matter (PM) or soot from diesel engine exhaust, significantly lowering fine particle emissions that contribute to respiratory problems and environmental degradation. The integration of CAT and DPF systems in vehicles enhances overall emission control, promoting cleaner air quality and compliance with stringent environmental regulations.

Choosing the Right System: CAT or DPF for Your Vehicle

Choosing the right emission control system depends on your vehicle type and operating conditions; Catalytic Converters (CAT) are ideal for gasoline engines, effectively reducing carbon monoxide and hydrocarbons through oxidation. Diesel Particulate Filters (DPF) are tailored for diesel engines, capturing and regenerating soot particles to minimize particulate matter emissions. Evaluating fuel type, engine load, and emission standards ensures optimal performance and compliance when selecting between CAT and DPF systems.

CAT vs DPF Infographic

cardiffo.com

cardiffo.com