Urea injection systems reduce nitrogen oxide (NOx) emissions by converting exhaust gases into nitrogen and water through selective catalytic reduction, making them highly effective for heavy-duty diesel engines. Lean NOx traps (LNTs) capture and store NOx during lean engine operation, then release and reduce it during rich conditions, offering a compact solution best suited for light-duty applications. Both technologies target NOx reduction but differ in efficiency, complexity, and operational environments, influencing their adoption based on vehicle type and emission standards.

Table of Comparison

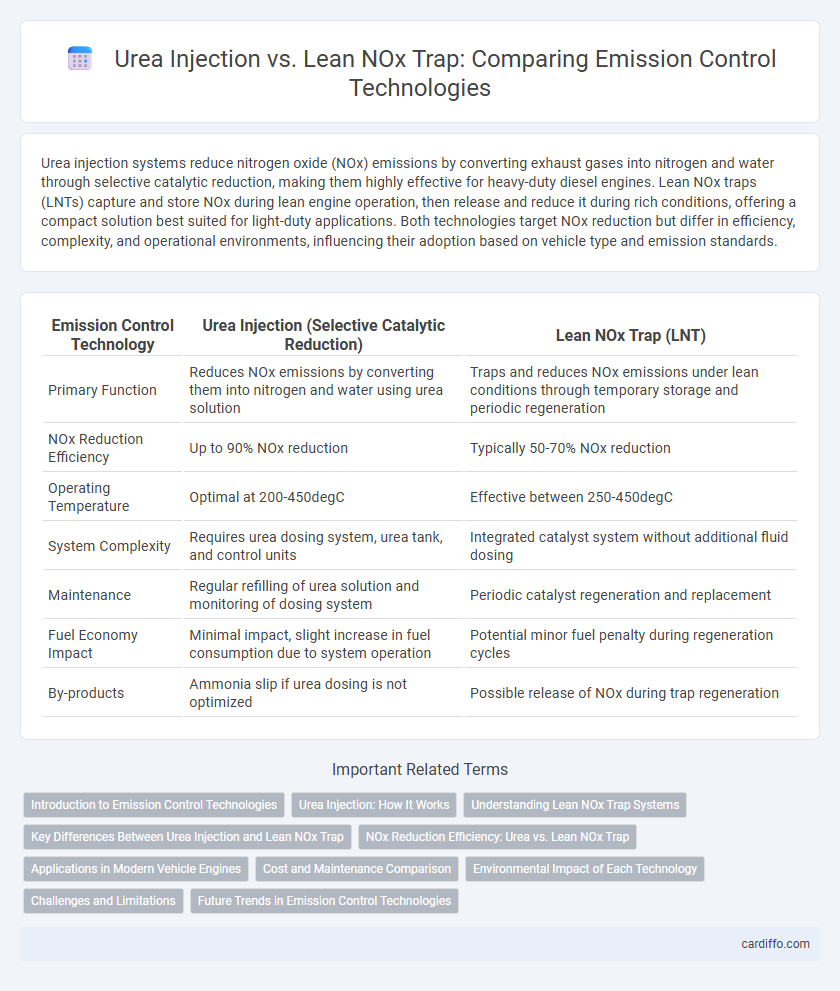

| Emission Control Technology | Urea Injection (Selective Catalytic Reduction) | Lean NOx Trap (LNT) |

|---|---|---|

| Primary Function | Reduces NOx emissions by converting them into nitrogen and water using urea solution | Traps and reduces NOx emissions under lean conditions through temporary storage and periodic regeneration |

| NOx Reduction Efficiency | Up to 90% NOx reduction | Typically 50-70% NOx reduction |

| Operating Temperature | Optimal at 200-450degC | Effective between 250-450degC |

| System Complexity | Requires urea dosing system, urea tank, and control units | Integrated catalyst system without additional fluid dosing |

| Maintenance | Regular refilling of urea solution and monitoring of dosing system | Periodic catalyst regeneration and replacement |

| Fuel Economy Impact | Minimal impact, slight increase in fuel consumption due to system operation | Potential minor fuel penalty during regeneration cycles |

| By-products | Ammonia slip if urea dosing is not optimized | Possible release of NOx during trap regeneration |

Introduction to Emission Control Technologies

Urea injection and Lean NOx Trap (LNT) are advanced emission control technologies designed to reduce nitrogen oxide (NOx) emissions from diesel engines. Urea injection utilizes a selective catalytic reduction (SCR) system where diesel exhaust fluid (DEF) is injected to chemically convert NOx into harmless nitrogen and water. Lean NOx Trap operates by adsorbing NOx during lean engine operation and periodically regenerating under rich conditions to convert trapped NOx into nitrogen, making both methods critical for meeting stringent emission standards such as Euro 6 and EPA Tier 4.

Urea Injection: How It Works

Urea injection, also known as Selective Catalytic Reduction (SCR), reduces NOx emissions by injecting a urea solution into the exhaust stream, where it reacts with NOx gases to form harmless nitrogen and water. The process relies on precise temperature control and catalytic converters to optimize chemical reactions, achieving emission reductions of up to 90%. Urea injection systems are widely used in diesel engines for compliance with stringent environmental regulations, enhancing air quality by significantly lowering nitrogen oxide output.

Understanding Lean NOx Trap Systems

Lean NOx Trap (LNT) systems efficiently reduce nitrogen oxide (NOx) emissions by adsorbing NOx during lean engine operation and periodically regenerating under rich conditions to release and convert stored NOx into nitrogen and oxygen. Unlike urea injection systems that rely on ammonia from urea solution for selective catalytic reduction (SCR), LNTs integrate adsorption and catalytic conversion in a single component, simplifying exhaust treatment. LNT technology is particularly effective for gasoline and lean-burn gasoline engines where consistent regeneration cycles optimize emission control without the need for additional reductants.

Key Differences Between Urea Injection and Lean NOx Trap

Urea injection reduces NOx emissions by converting nitrogen oxides into nitrogen and water through selective catalytic reduction (SCR), requiring a constant supply of urea solution. Lean NOx trap (LNT) technology stores NOx on a catalyst during lean engine operation and periodically reduces it during rich conditions without external reductants. Urea injection systems generally offer higher efficiency and scalability for heavy-duty applications, while LNTs are more compact but often face challenges with sulfur poisoning and durability.

NOx Reduction Efficiency: Urea vs. Lean NOx Trap

Urea injection systems achieve NOx reduction efficiencies of up to 90% by converting nitrogen oxides into harmless nitrogen and water through selective catalytic reduction (SCR). Lean NOx traps (LNT) typically offer NOx reduction efficiencies between 60% and 80%, relying on adsorption and periodic regeneration cycles to capture and reduce emissions. The higher NOx removal efficiency of urea injection makes it the preferred choice for stringent emission standards in heavy-duty diesel engines.

Applications in Modern Vehicle Engines

Urea injection systems, commonly used in selective catalytic reduction (SCR) technology, effectively reduce NOx emissions in heavy-duty diesel engines and commercial vehicles by converting nitrogen oxides into harmless nitrogen and water. Lean NOx trap (LNT) catalysts are typically applied in light-duty gasoline and diesel engines, particularly in urban driving conditions where frequent regeneration cycles can be maintained. Modern vehicle engines integrate urea injection for sustained highway performance and LNT for efficient short-trip emission control, optimizing compliance with stringent Euro 6 and EPA Tier 3 standards.

Cost and Maintenance Comparison

Urea injection systems typically have lower upfront costs but require continuous supply of urea and regular refilling, leading to higher operational expenses. Lean NOx traps demand higher initial investment due to complex catalyst materials and periodic regeneration cycles, which involve frequent maintenance to ensure efficiency. Maintenance costs for lean NOx traps are often greater than those for urea injection, driven by catalyst replacement and system diagnostics.

Environmental Impact of Each Technology

Urea injection reduces nitrogen oxide (NOx) emissions by converting them into nitrogen and water, significantly lowering air pollution and contributing to improved air quality. Lean NOx trap (LNT) technology captures and stores NOx during lean combustion, then periodically reduces it to nitrogen using rich fuel conditions, minimizing harmful emissions but requiring precise control to avoid ammonia slip. Both technologies aid in meeting stringent emission standards, with urea injection generally offering higher efficiency in NOx reduction and LNT providing an effective solution for smaller engines and lighter-duty applications.

Challenges and Limitations

Urea injection systems face challenges such as ammonia slip, high operational costs, and dependence on precise dosing to effectively reduce NOx emissions. Lean NOx traps encounter limitations including catalyst degradation over time, sensitivity to sulfur poisoning, and reduced efficiency under transient engine conditions. Both technologies demand careful maintenance and optimization to ensure compliance with stringent emission standards.

Future Trends in Emission Control Technologies

Emerging emission control technologies emphasize the integration of urea injection systems with advanced lean NOx traps to achieve superior nitrogen oxide reduction in diesel engines. Future trends highlight the development of more efficient catalysts and optimized urea dosing strategies to enhance NOx conversion rates while minimizing ammonia slip and particulate emissions. Innovations in sensor technology and real-time monitoring are driving smarter, adaptive emission control systems that comply with stringent global environmental regulations.

Urea injection vs Lean NOx trap Infographic

cardiffo.com

cardiffo.com