OBD-I and OBD-II are diagnostic systems used to monitor vehicle emissions and engine performance. OBD-I, introduced in the 1980s, offers limited diagnostic capabilities and varies by manufacturer, while OBD-II, mandated since 1996, provides standardized protocols and more comprehensive emission data. The advanced sensors and real-time data from OBD-II help improve emission control and ensure compliance with environmental regulations.

Table of Comparison

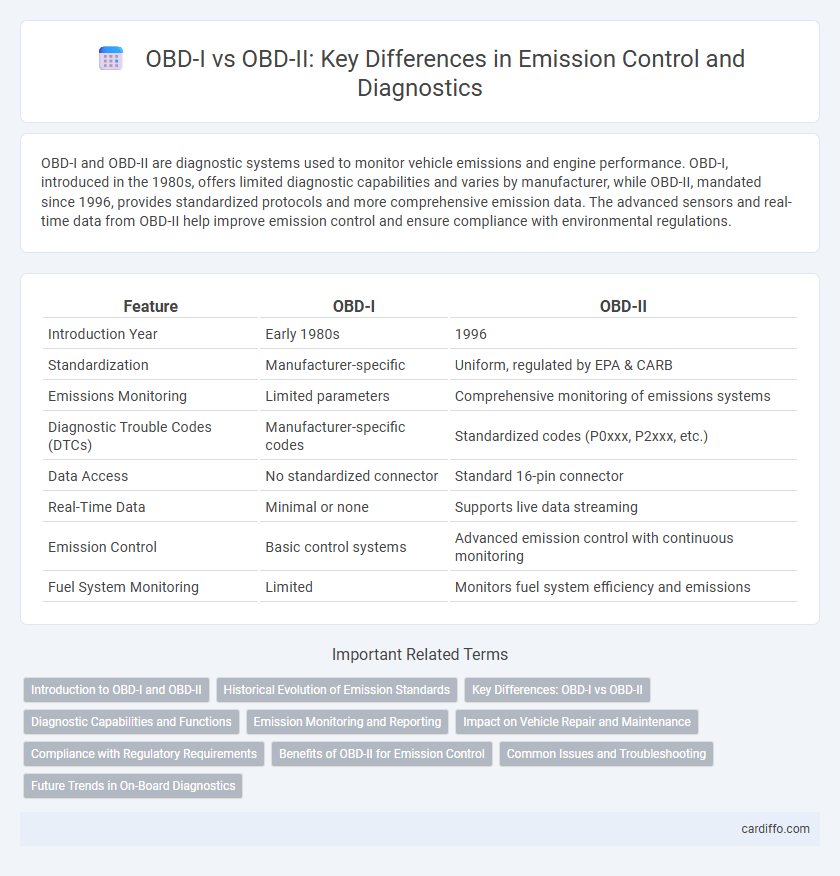

| Feature | OBD-I | OBD-II |

|---|---|---|

| Introduction Year | Early 1980s | 1996 |

| Standardization | Manufacturer-specific | Uniform, regulated by EPA & CARB |

| Emissions Monitoring | Limited parameters | Comprehensive monitoring of emissions systems |

| Diagnostic Trouble Codes (DTCs) | Manufacturer-specific codes | Standardized codes (P0xxx, P2xxx, etc.) |

| Data Access | No standardized connector | Standard 16-pin connector |

| Real-Time Data | Minimal or none | Supports live data streaming |

| Emission Control | Basic control systems | Advanced emission control with continuous monitoring |

| Fuel System Monitoring | Limited | Monitors fuel system efficiency and emissions |

Introduction to OBD-I and OBD-II

OBD-I, introduced in the early 1980s, provided basic on-board diagnostics focused on engine performance and emissions control through manufacturer-specific systems. OBD-II, mandated in 1996, standardized diagnostic trouble codes and enhanced monitoring capabilities, covering broader vehicle systems to ensure stricter emission standards compliance. The transition to OBD-II enabled more precise detection of emission-related malfunctions, improving overall air quality and vehicle maintenance efficiency.

Historical Evolution of Emission Standards

OBD-I systems, introduced in the early 1980s, marked the first standardized approach to vehicle emissions monitoring, focusing mainly on basic diagnostics for engine components to control pollutants. The transition to OBD-II in the mid-1990s brought enhanced real-time emissions data collection, expanded sensor networks, and rigorous federal mandates like the Clean Air Act Amendments, driving significant improvements in emission control technologies. This evolution reflects the automotive industry's response to increasingly stringent environmental regulations aimed at reducing ozone-forming pollutants and greenhouse gases from on-road vehicles.

Key Differences: OBD-I vs OBD-II

OBD-I systems, implemented in the early 1980s, offered limited diagnostic capabilities with manufacturer-specific codes and lacked standardized communication protocols. In contrast, OBD-II, mandated from 1996 onward, provides comprehensive emissions monitoring with universal standardized codes (DTCs), improved sensor data, and real-time diagnostics accessible via standardized connectors. OBD-II systems enhance emissions control efficiency by enabling more precise fault detection and supporting advanced engine management compared to the rudimentary OBD-I technology.

Diagnostic Capabilities and Functions

OBD-II offers advanced diagnostic capabilities compared to OBD-I, providing real-time data access and standardized trouble codes across all vehicles, which facilitates more accurate emission control monitoring. OBD-II systems continuously monitor critical components such as the catalytic converter, oxygen sensors, and EVAP systems, enhancing pollutant detection and compliance with stricter emission regulations. In contrast, OBD-I employs manufacturer-specific codes with limited diagnostic scope, primarily focused on engine performance rather than comprehensive emission system evaluation.

Emission Monitoring and Reporting

OBD-II systems provide comprehensive emission monitoring by continuously checking critical components such as the catalytic converter, oxygen sensors, and evaporative emission control systems, enabling real-time reporting of faults. In contrast, OBD-I offers limited emission diagnostics with partial monitoring of components and often lacks standardized reporting protocols, reducing its effectiveness in detecting emission-related issues. The standardized trouble codes and enhanced sensor integration in OBD-II significantly improve emission control and regulatory compliance.

Impact on Vehicle Repair and Maintenance

OBD-I systems provide limited diagnostic information, making it harder for technicians to identify and fix emission-related issues efficiently, often leading to longer repair times and increased maintenance costs. OBD-II, with standardized and comprehensive fault codes, allows for quicker diagnosis of emission system problems, improving repair accuracy and reducing downtime. Enhanced OBD-II data availability also supports preventative maintenance, ultimately extending vehicle lifespan and ensuring compliance with stricter emission standards.

Compliance with Regulatory Requirements

OBD-II systems offer more comprehensive compliance with current emission regulations by continuously monitoring a broader range of vehicle systems and providing standardized diagnostic trouble codes. In contrast, OBD-I systems have limited monitoring capabilities and less uniformity across manufacturers, making regulatory compliance less stringent and effective. Modern emission standards rely heavily on OBD-II technology to ensure consistent detection and reporting of emissions-related faults.

Benefits of OBD-II for Emission Control

OBD-II provides comprehensive real-time monitoring of vehicle emissions, enabling early detection and precise diagnosis of emission-related issues compared to OBD-I. Its standardized diagnostic trouble codes (DTCs) facilitate efficient repairs and compliance with stringent environmental regulations. Enhanced sensor integration in OBD-II systems ensures improved accuracy in controlling pollutants, significantly reducing harmful emissions.

Common Issues and Troubleshooting

OBD-I systems, used before 1996, often face issues such as inaccurate sensor data and limited diagnostic capability, making troubleshooting more complex due to proprietary codes and lack of standardization. OBD-II, standardized across all vehicles post-1996, offers enhanced emission monitoring with universal codes, facilitating easier identification and resolution of problems like catalytic converter efficiency and oxygen sensor failures. Diagnostic tools for OBD-II provide streamlined access to real-time data and freeze frame information, significantly improving emission-related troubleshooting efficiency.

Future Trends in On-Board Diagnostics

OBD-II systems offer enhanced emission monitoring capabilities with standardized data protocols, enabling real-time diagnostics and predictive maintenance, which surpass the limited functions of OBD-I. Future trends in On-Board Diagnostics emphasize wireless connectivity, integration with telematics, and AI-driven analytics to improve emission control and regulatory compliance. Advancements in sensor technology and cloud-based platforms will enable more accurate detection of pollutants and proactive emission management.

OBD-I vs OBD-II Infographic

cardiffo.com

cardiffo.com