Selective Catalytic Reduction (SCR) and Lean NOx Trap (LNT) are two prominent emission control technologies for reducing nitrogen oxides (NOx) from diesel engines. SCR utilizes a urea-based reductant injected into the exhaust stream to convert NOx into nitrogen and water, offering high efficiency and scalability for heavy-duty applications. LNT captures and stores NOx on a catalyst during lean operation and periodically reduces it during rich conditions, providing a compact solution suitable for light-duty vehicles but generally lower NOx reduction efficiency compared to SCR.

Table of Comparison

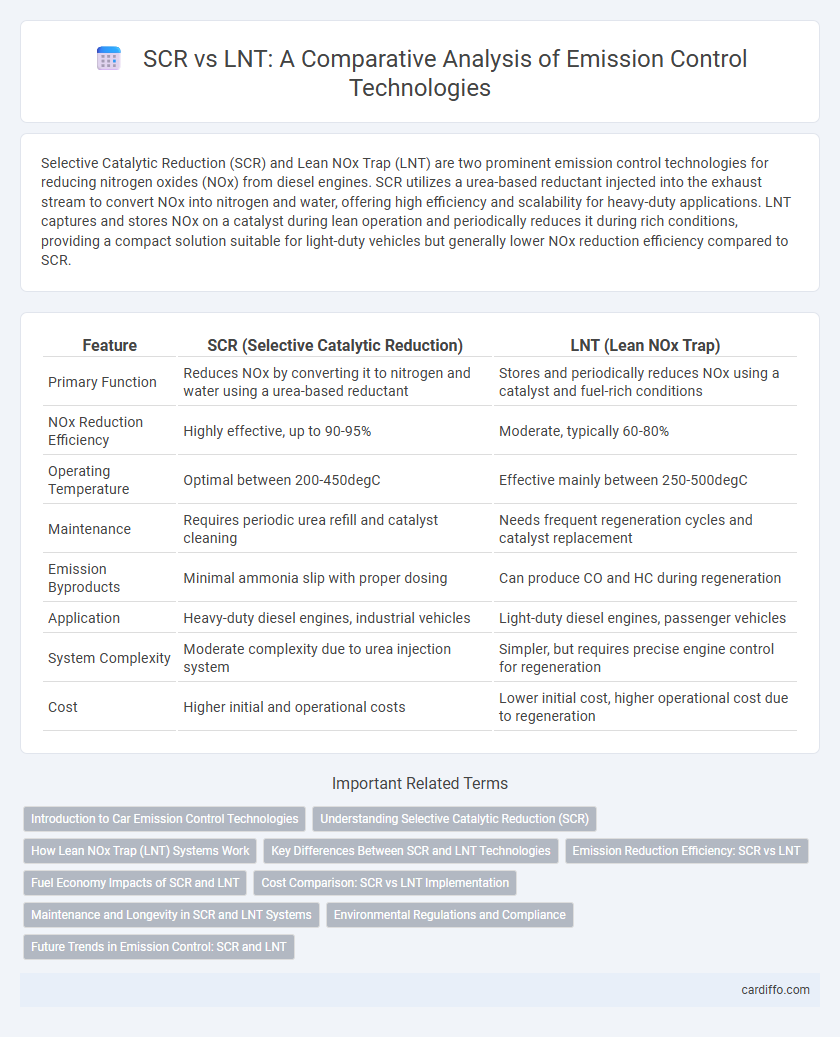

| Feature | SCR (Selective Catalytic Reduction) | LNT (Lean NOx Trap) |

|---|---|---|

| Primary Function | Reduces NOx by converting it to nitrogen and water using a urea-based reductant | Stores and periodically reduces NOx using a catalyst and fuel-rich conditions |

| NOx Reduction Efficiency | Highly effective, up to 90-95% | Moderate, typically 60-80% |

| Operating Temperature | Optimal between 200-450degC | Effective mainly between 250-500degC |

| Maintenance | Requires periodic urea refill and catalyst cleaning | Needs frequent regeneration cycles and catalyst replacement |

| Emission Byproducts | Minimal ammonia slip with proper dosing | Can produce CO and HC during regeneration |

| Application | Heavy-duty diesel engines, industrial vehicles | Light-duty diesel engines, passenger vehicles |

| System Complexity | Moderate complexity due to urea injection system | Simpler, but requires precise engine control for regeneration |

| Cost | Higher initial and operational costs | Lower initial cost, higher operational cost due to regeneration |

Introduction to Car Emission Control Technologies

Selective Catalytic Reduction (SCR) and Lean-NOx Trap (LNT) are advanced car emission control technologies designed to reduce nitrogen oxide (NOx) emissions in diesel engines. SCR uses a urea-based solution to convert NOx into nitrogen and water through a catalytic reaction, proving highly effective in heavy-duty vehicles and meeting stringent emission standards like Euro 6 and Tier 3. LNT stores and subsequently reduces NOx during rich combustion phases, offering a compact solution primarily for light-duty applications but with less efficiency under varying driving conditions compared to SCR.

Understanding Selective Catalytic Reduction (SCR)

Selective Catalytic Reduction (SCR) is an advanced emission control technology that reduces nitrogen oxides (NOx) from diesel engine exhaust by injecting a urea-based reductant into the exhaust stream. The SCR system converts NOx into harmless nitrogen (N2) and water (H2O) through a catalytic reaction, achieving reduction efficiencies of up to 90%. In comparison to Lean NOx Traps (LNT), SCR offers superior NOx reduction performance, especially for heavy-duty vehicles operating under varied load conditions.

How Lean NOx Trap (LNT) Systems Work

Lean NOx Trap (LNT) systems reduce nitrogen oxides (NOx) emissions by adsorbing NOx onto a catalytic surface during lean engine operation and subsequently releasing and reducing them to nitrogen during rich conditions. The LNT stores NOx in a trap composed of materials such as barium oxide and platinum, which captures NOx molecules when excess oxygen is present. During periodic rich phases, the trapped NOx is chemically converted to nitrogen and water, enabling efficient NOx control in lean-burn engines without the need for urea injection.

Key Differences Between SCR and LNT Technologies

Selective Catalytic Reduction (SCR) uses ammonia or urea to convert nitrogen oxides (NOx) into nitrogen and water, achieving NOx reduction efficiencies up to 90%, while Lean NOx Trap (LNT) technology adsorbs NOx onto a catalyst during lean conditions and periodically reduces it during rich conditions with lower overall efficiency around 60-70%. SCR systems require separate reductant injection and complex controls but perform better on highways and large engines, whereas LNTs are simpler and more compact, making them suitable for smaller engines and urban driving cycles. SCR catalysts typically operate at temperatures between 200-450degC, while LNT systems function efficiently within 250-400degC, influencing their application based on exhaust temperature profiles.

Emission Reduction Efficiency: SCR vs LNT

Selective Catalytic Reduction (SCR) systems achieve emission reduction efficiencies of up to 90% for nitrogen oxides (NOx), significantly outperforming Lean NOx Trap (LNT) systems, which typically reach around 50-70% efficiency. SCR technology catalytically converts NOx into nitrogen and water using ammonia or urea, providing more consistent and effective reduction across varying engine loads. LNT relies on adsorption and periodic regeneration, resulting in less stable emission control and higher hydrocarbon slip compared to SCR.

Fuel Economy Impacts of SCR and LNT

Selective Catalytic Reduction (SCR) systems generally improve fuel economy by allowing engines to operate at higher combustion temperatures and leaner air-fuel ratios, reducing nitrogen oxides (NOx) without significant fuel penalties. Lean NOx Traps (LNT), while effective at NOx reduction, often require periodic fuel-rich regeneration cycles that increase fuel consumption and decrease overall fuel efficiency. Studies show SCR-equipped vehicles achieve better fuel economy compared to LNT systems, especially in heavy-duty diesel applications.

Cost Comparison: SCR vs LNT Implementation

SCR (Selective Catalytic Reduction) systems generally incur higher initial implementation costs due to the complex catalyst and urea injection components required, whereas LNT (Lean NOx Trap) systems involve lower upfront expenses but often result in higher maintenance and operational costs over time. Lifetime cost analysis reveals that SCR tends to achieve better fuel efficiency and reduced NOx emissions, offsetting the higher capital investment through lower operational costs and potential regulatory compliance savings. LNT systems may be more cost-effective for smaller-scale or less stringent applications where initial capital outlay is a primary concern, but SCR is preferred for long-term cost efficiency and superior emission control in heavy-duty or high-demand environments.

Maintenance and Longevity in SCR and LNT Systems

Selective Catalytic Reduction (SCR) systems generally require more frequent maintenance due to the need for AdBlue or urea solution replenishment and injector cleaning, while Lean NOx Trap (LNT) systems involve periodic regeneration cycles that can impact catalyst durability. SCR catalysts typically exhibit longer lifespan, often exceeding 100,000 miles, as they rely on continuous chemical reduction of NOx, whereas LNT catalysts may degrade faster due to repeated oxidation and reduction cycles. Effective maintenance strategies for SCR include regular monitoring of dosing systems and catalyst performance, whereas LNT systems require attention to the sulfur content in fuel and regeneration management to maximize longevity.

Environmental Regulations and Compliance

Selective Catalytic Reduction (SCR) systems achieve higher NOx reduction efficiency compared to Lean NOx Traps (LNT), making SCR the preferred technology for meeting stringent environmental regulations such as Euro 6 and EPA Tier 4 standards. SCR technology consistently complies with evolving global emission limits by converting NOx into harmless nitrogen and water, while LNTs face challenges with catalyst degradation and reduced effectiveness in high-mileage applications. Regulatory agencies increasingly favor SCR systems for their proven durability and ability to sustain compliance with low-emission mandates in on-road and off-road diesel engines.

Future Trends in Emission Control: SCR and LNT

Selective Catalytic Reduction (SCR) technology is expected to dominate future emission control strategies due to its high efficiency in reducing nitrogen oxides (NOx) in heavy-duty diesel engines. Lean NOx Traps (LNT) will continue to evolve with enhanced catalyst formulations improving cold-start and low-load performance, targeting passenger vehicles and light-duty applications. Integration of SCR and LNT systems with advanced sensors and onboard diagnostics will optimize emissions reduction while meeting increasingly stringent global regulations.

SCR vs LNT Infographic

cardiffo.com

cardiffo.com