Engine knock occurs when fuel combusts unevenly, creating a knocking or pinging sound that may damage cylinder components, while piston slap results from the piston rocking inside the cylinder, producing a distinct tapping noise during cold starts or low RPMs. Engine knock signals combustion irregularities that can reduce efficiency and increase engine wear, whereas piston slap often diminishes as the engine warms up and is usually less harmful. Identifying the difference is crucial for diagnosing engine issues and preventing long-term damage.

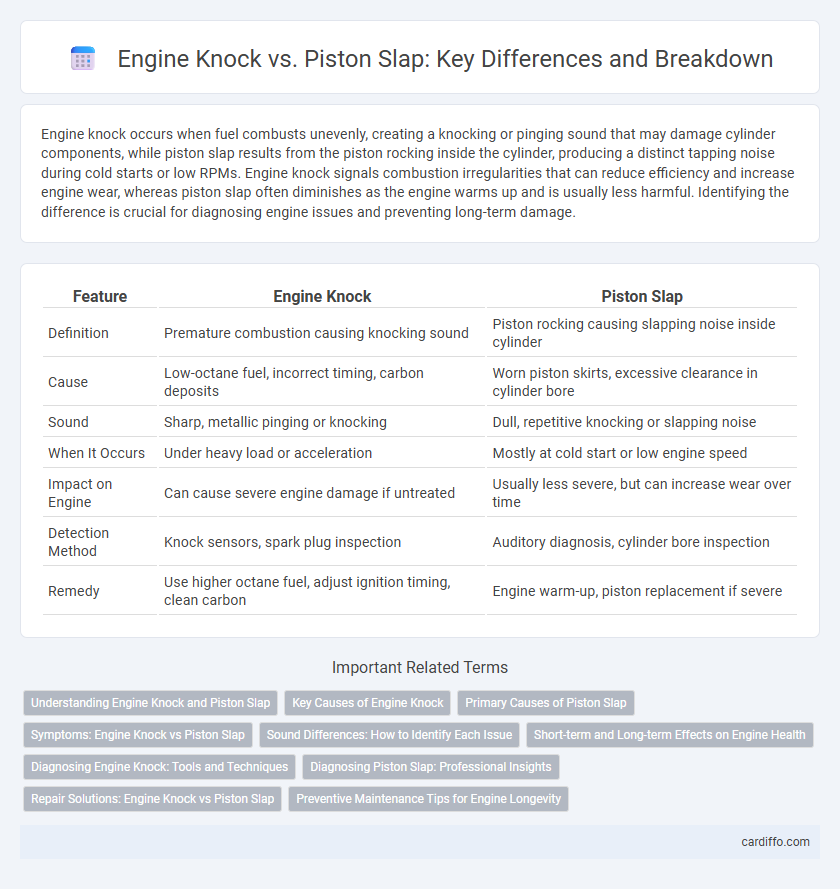

Table of Comparison

| Feature | Engine Knock | Piston Slap |

|---|---|---|

| Definition | Premature combustion causing knocking sound | Piston rocking causing slapping noise inside cylinder |

| Cause | Low-octane fuel, incorrect timing, carbon deposits | Worn piston skirts, excessive clearance in cylinder bore |

| Sound | Sharp, metallic pinging or knocking | Dull, repetitive knocking or slapping noise |

| When It Occurs | Under heavy load or acceleration | Mostly at cold start or low engine speed |

| Impact on Engine | Can cause severe engine damage if untreated | Usually less severe, but can increase wear over time |

| Detection Method | Knock sensors, spark plug inspection | Auditory diagnosis, cylinder bore inspection |

| Remedy | Use higher octane fuel, adjust ignition timing, clean carbon | Engine warm-up, piston replacement if severe |

Understanding Engine Knock and Piston Slap

Engine knock occurs when fuel combusts unevenly in the cylinder, causing a sharp metallic noise and potential damage to the pistons and valves. Piston slap arises from excessive clearance between the piston and cylinder wall, producing a distinct knocking sound during cold starts or light acceleration. Differentiating engine knock from piston slap is crucial for accurate diagnosis and effective repair to maintain engine performance and longevity.

Key Causes of Engine Knock

Engine knock primarily occurs due to premature combustion of the air-fuel mixture in the cylinder, often caused by low-octane gasoline, incorrect ignition timing, or excessive engine temperature. Carbon deposits on the piston crown and cylinder walls increase compression and create hot spots that initiate knocking. In contrast, piston slap results from piston skirt clearance and wear, not combustion issues, making fuel quality and timing the essential factors distinguishing engine knock.

Primary Causes of Piston Slap

Piston slap primarily occurs due to excessive clearance between the piston and cylinder wall, often caused by engine wear, cold starts, or improper piston sizing. This condition results in the piston rocking side-to-side within the cylinder bore, creating a distinct knocking noise during operation. Metallurgical issues such as poor piston material or inadequate lubrication further exacerbate piston slap by increasing friction and wear on the cylinder walls.

Symptoms: Engine Knock vs Piston Slap

Engine knock presents as a metallic rattling noise during acceleration or under load, often caused by premature fuel combustion. Piston slap produces a distinct knocking sound primarily during cold starts, resulting from excessive clearance between the piston and cylinder wall. While engine knock can lead to performance loss and engine damage if untreated, piston slap usually diminishes as the engine warms up.

Sound Differences: How to Identify Each Issue

Engine knock produces a sharp, metallic pinging or knocking sound that intensifies with acceleration and engine load, often indicating abnormal combustion. Piston slap creates a deeper, rhythmic knocking noise primarily during cold starts and low RPMs, caused by pistons rocking within the cylinder bore. Identifying these distinct sound differences helps diagnose underlying engine issues and determine whether timing, fuel quality, or piston wear is the root cause.

Short-term and Long-term Effects on Engine Health

Engine knock causes immediate damage to engine components such as pistons and cylinder walls, leading to decreased performance and increased wear in the short term. Piston slap results in a distinct noise from loose piston-to-cylinder clearance, causing gradual wear and potential scoring over prolonged use. Long-term exposure to engine knock can lead to severe engine damage including cracked pistons and blown head gaskets, while extended piston slap often results in reduced compression and oil consumption issues.

Diagnosing Engine Knock: Tools and Techniques

Diagnosing engine knock involves using a combination of electronic knock sensors and advanced diagnostic tools such as oscilloscopes to detect abnormal combustion patterns. Visual inspection with a borescope can identify piston slap or damage within the cylinder walls, while sound analysis apps help distinguish between consistent knocking and intermittent piston slap noises. Combining sensor data with real-time engine performance monitoring enables accurate identification and effective resolution of engine issues.

Diagnosing Piston Slap: Professional Insights

Diagnosing piston slap involves identifying the characteristic metallic knocking noise during engine startup or cold operation, which typically diminishes as the engine warms up. Professional mechanics use specialized diagnostic tools such as stethoscopes or vibration analyzers to distinguish piston slap from engine knock caused by pre-ignition or detonation. Accurate diagnosis requires comprehensive inspection of piston clearances and cylinder bore wear, often utilizing borescope imaging for precise assessment.

Repair Solutions: Engine Knock vs Piston Slap

Engine knock repair solutions often involve using higher-octane fuel, adjusting ignition timing, or replacing damaged spark plugs and sensors to prevent pre-detonation and restore smooth combustion. Piston slap repair typically requires inspecting and replacing worn piston skirts or cylinders, along with restoring proper clearances to eliminate the loose fit causing the noise. Accurate diagnosis is crucial to determine whether the issue is caused by combustion irregularities or mechanical wear for effective repair.

Preventive Maintenance Tips for Engine Longevity

Engine knock and piston slap both indicate abnormal combustion or mechanical issues that can accelerate engine wear if left unaddressed. Regularly inspecting and replacing spark plugs, using high-quality fuel, and maintaining proper oil levels help prevent engine knock by ensuring efficient combustion and lubrication. To avoid piston slap, monitor oil pressure closely, use recommended oil viscosity, and perform timely oil changes to maintain the optimal clearance between pistons and cylinder walls.

Engine knock vs piston slap Infographic

cardiffo.com

cardiffo.com