Loose connections in pet breakdown situations often cause intermittent electrical failures due to unstable contact, while corroded terminals lead to persistent issues by hindering proper current flow. Identifying a loose connection requires checking for movement or gaps in wires, whereas corroded terminals show visible signs of rust or buildup that disrupt conductivity. Regular inspection and maintenance of terminals prevent corrosion, ensuring reliable connections and reducing the risk of breakdowns.

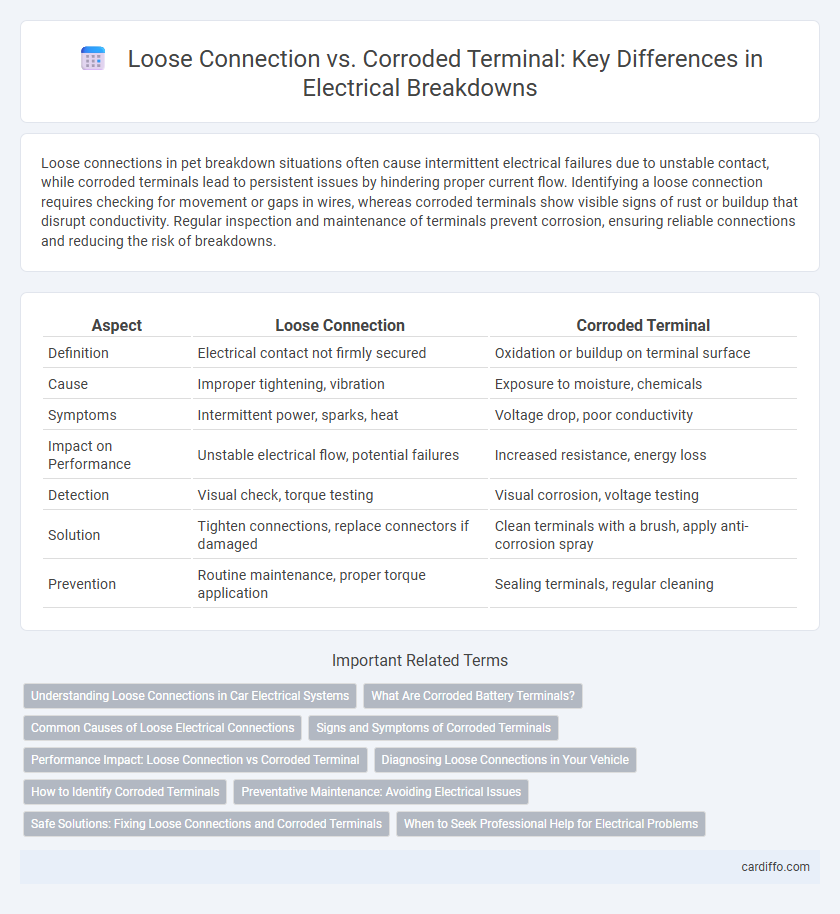

Table of Comparison

| Aspect | Loose Connection | Corroded Terminal |

|---|---|---|

| Definition | Electrical contact not firmly secured | Oxidation or buildup on terminal surface |

| Cause | Improper tightening, vibration | Exposure to moisture, chemicals |

| Symptoms | Intermittent power, sparks, heat | Voltage drop, poor conductivity |

| Impact on Performance | Unstable electrical flow, potential failures | Increased resistance, energy loss |

| Detection | Visual check, torque testing | Visual corrosion, voltage testing |

| Solution | Tighten connections, replace connectors if damaged | Clean terminals with a brush, apply anti-corrosion spray |

| Prevention | Routine maintenance, proper torque application | Sealing terminals, regular cleaning |

Understanding Loose Connections in Car Electrical Systems

Loose connections in car electrical systems cause intermittent power loss and voltage drops, leading to malfunctions in critical components like ignition coils and sensors. These faults differ from corroded terminals, which create resistive barriers due to oxidation, often resulting in poor conductivity and increased heat. Ensuring tight, clean terminal connections minimizes electrical failures and maintains optimal vehicle performance.

What Are Corroded Battery Terminals?

Corroded battery terminals occur when the metal connectors on a car battery undergo chemical reactions, usually caused by acid leaks or moisture, resulting in the buildup of white, ashy deposits or rust. This corrosion impedes the electrical flow between the battery and the vehicle's electrical system, leading to starting problems or reduced battery performance. Unlike loose connections, which are mechanical issues involving poor physical contact, corroded terminals require cleaning or replacement to restore effective conductivity.

Common Causes of Loose Electrical Connections

Loose electrical connections often result from vibration, thermal expansion, or improper installation, causing intermittent power loss and potential equipment failure. Corroded terminals arise due to moisture, oxidation, or chemical exposure, leading to increased resistance and overheating. Regular inspection and maintenance are essential to identify loose wires, worn connectors, and signs of corrosion to prevent breakdowns.

Signs and Symptoms of Corroded Terminals

Corroded terminals often exhibit signs such as a white or greenish powdery residue around the connection point, which indicates oxidation or chemical buildup. These terminals typically cause intermittent electrical problems, including flickering lights, slow engine cranking, or complete failure of the electrical system. Unlike loose connections, corroded terminals may resist proper tightening and display visible rust or discoloration, leading to increased resistance and poor conductivity.

Performance Impact: Loose Connection vs Corroded Terminal

Loose connections cause intermittent electrical flow, leading to inconsistent performance and potential system failures. Corroded terminals create high resistance, resulting in voltage drops, reduced power efficiency, and overheating risks. Both conditions degrade overall equipment reliability but corrosion is more likely to cause prolonged damage and permanent component failure.

Diagnosing Loose Connections in Your Vehicle

Diagnosing loose connections in your vehicle involves inspecting wiring harnesses and terminal joints for any signs of movement or poor contact, which can result in intermittent electrical issues or complete failure of components. Use a multimeter to test for voltage drop or continuity at suspected loose connections to confirm the problem, as loose terminals often cause fluctuating readings. Unlike corroded terminals that display visible rust or buildup impeding conductivity, loose connections may appear clean but fail due to physical displacement or insufficient tightening.

How to Identify Corroded Terminals

Corroded terminals can be identified by visible signs of oxidation, such as green or white powdery deposits around the battery or cable connections. A corroded terminal often causes decreased electrical conductivity, leading to intermittent power issues or difficulty starting the vehicle. Using a voltage tester or multimeter to check for voltage drops across terminals can confirm corrosion-related connectivity problems.

Preventative Maintenance: Avoiding Electrical Issues

Loose connections can cause intermittent power failures and increased resistance, leading to heat buildup and potential circuit damage, while corroded terminals degrade electrical conductivity and accelerate component wear. Preventative maintenance involving regular inspection, tightening of terminal connections, and cleaning or replacement of corroded parts significantly reduces the risk of electrical failures. Implementing these practices ensures system reliability and prolongs the lifespan of electrical equipment.

Safe Solutions: Fixing Loose Connections and Corroded Terminals

Fixing loose connections requires tightening or re-crimping wires to ensure a secure electrical path and prevent overheating or arcing. Safe solutions for corroded terminals involve cleaning the corrosion with a wire brush or using a terminal cleaner, followed by applying dielectric grease to protect against future corrosion. Proper maintenance and regular inspections help avoid electrical failures and enhance system reliability.

When to Seek Professional Help for Electrical Problems

Loose connections often cause intermittent power issues and flickering lights, while corroded terminals lead to poor conductivity and potential overheating. If troubleshooting these symptoms involves accessing wiring inside walls or complex circuit components, professional electricians should be contacted to prevent hazards. Signs like persistent sparking, burning smells, or frequent breaker trips indicate urgent need for expert assessment and repair.

Loose connection vs corroded terminal Infographic

cardiffo.com

cardiffo.com