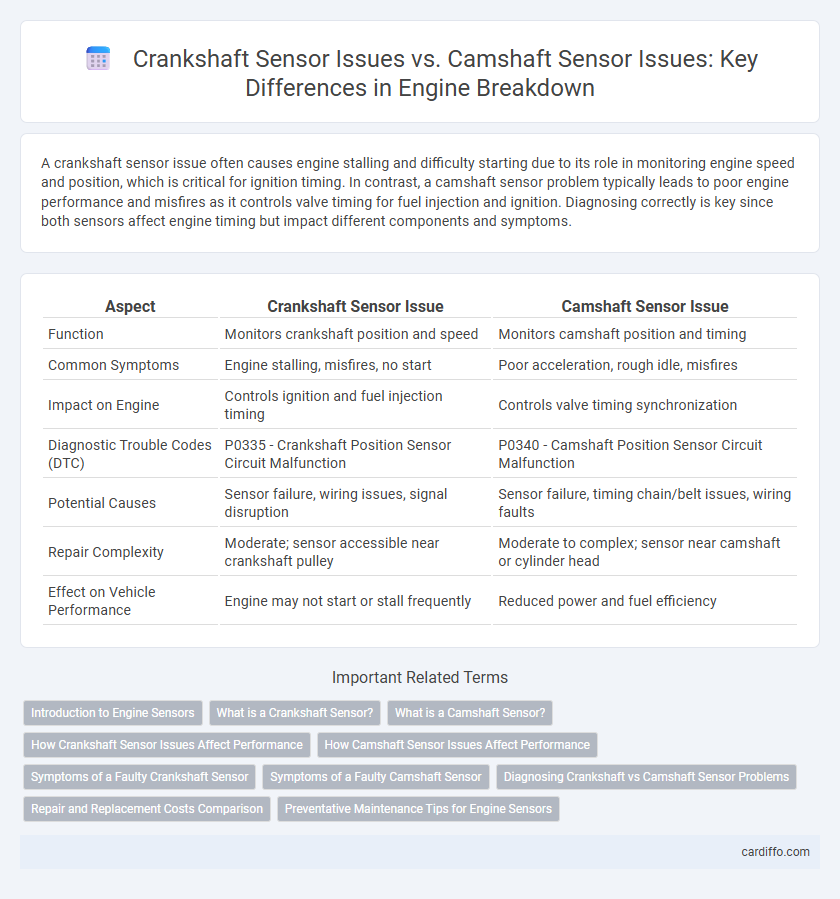

A crankshaft sensor issue often causes engine stalling and difficulty starting due to its role in monitoring engine speed and position, which is critical for ignition timing. In contrast, a camshaft sensor problem typically leads to poor engine performance and misfires as it controls valve timing for fuel injection and ignition. Diagnosing correctly is key since both sensors affect engine timing but impact different components and symptoms.

Table of Comparison

| Aspect | Crankshaft Sensor Issue | Camshaft Sensor Issue |

|---|---|---|

| Function | Monitors crankshaft position and speed | Monitors camshaft position and timing |

| Common Symptoms | Engine stalling, misfires, no start | Poor acceleration, rough idle, misfires |

| Impact on Engine | Controls ignition and fuel injection timing | Controls valve timing synchronization |

| Diagnostic Trouble Codes (DTC) | P0335 - Crankshaft Position Sensor Circuit Malfunction | P0340 - Camshaft Position Sensor Circuit Malfunction |

| Potential Causes | Sensor failure, wiring issues, signal disruption | Sensor failure, timing chain/belt issues, wiring faults |

| Repair Complexity | Moderate; sensor accessible near crankshaft pulley | Moderate to complex; sensor near camshaft or cylinder head |

| Effect on Vehicle Performance | Engine may not start or stall frequently | Reduced power and fuel efficiency |

Introduction to Engine Sensors

Engine sensors such as the crankshaft sensor and camshaft sensor play critical roles in monitoring engine timing and ensuring optimal performance. The crankshaft sensor measures the rotational speed and position of the crankshaft, enabling precise fuel injection and ignition timing, while the camshaft sensor tracks the position of the camshaft to control the timing of valve operation. Faults in either sensor can lead to engine misfires, stalling, or failure to start, highlighting their importance in electronic engine management systems.

What is a Crankshaft Sensor?

A crankshaft sensor monitors the rotational speed and position of the crankshaft, providing critical data to the engine control unit (ECU) for ignition timing and fuel injection. Unlike the camshaft sensor, which tracks the camshaft position for valve timing, a faulty crankshaft sensor often causes engine stalling, misfires, or failure to start. Accurate crankshaft sensor signals ensure precise engine synchronization and optimal performance, making it a vital component in engine management systems.

What is a Camshaft Sensor?

A camshaft sensor monitors the position and rotational speed of the camshaft, providing critical data to the engine control unit (ECU) for precise timing of fuel injection and ignition. Unlike the crankshaft sensor, which tracks the crankshaft's position to manage engine speed, the camshaft sensor ensures valves open and close at the correct intervals, directly impacting engine performance. Malfunctions in the camshaft sensor can cause misfires, poor acceleration, and stalling, making it essential for efficient engine operation.

How Crankshaft Sensor Issues Affect Performance

Crankshaft sensor issues disrupt engine timing by miscommunicating the crankshaft position to the engine control unit, causing misfires, stalling, or failure to start. Unlike camshaft sensor problems that primarily affect valve timing, crankshaft sensor faults have a more immediate and critical impact on ignition and fuel injection sequences. This leads to reduced engine performance, decreased fuel efficiency, and increased emissions, making diagnosis and repair crucial for maintaining optimal engine function.

How Camshaft Sensor Issues Affect Performance

Camshaft sensor issues disrupt engine timing by sending incorrect data to the engine control unit, causing misfires, stalling, and reduced fuel efficiency. Unlike crankshaft sensor problems that mainly affect engine starting and RPM detection, camshaft sensor faults specifically hinder variable valve timing and ignition timing, leading to rough idling and poor acceleration. Diagnosing camshaft sensor malfunctions quickly is crucial to maintain optimal engine performance and prevent extensive damage.

Symptoms of a Faulty Crankshaft Sensor

Symptoms of a faulty crankshaft sensor include engine misfires, stalling, and difficulty starting the vehicle due to inaccurate engine timing data. Unlike camshaft sensor issues that primarily affect valve timing and ignition synchronization, crankshaft sensor failure directly disrupts the engine's ability to monitor crankshaft position and speed. This often results in erratic idling, reduced engine performance, and triggering of the check engine light with diagnostic trouble codes related to crankshaft position sensor malfunctions.

Symptoms of a Faulty Camshaft Sensor

A faulty camshaft sensor often causes engine misfires, poor acceleration, and difficulty starting as it disrupts the engine timing. Unlike a crankshaft sensor issue, the camshaft sensor malfunction may trigger the check engine light specifically with codes related to camshaft position. Erratic idle and stalling are common symptoms that help distinguish camshaft sensor problems from crankshaft sensor failures.

Diagnosing Crankshaft vs Camshaft Sensor Problems

Diagnosing crankshaft sensor problems involves checking for irregular engine stalling, misfires, or no-start conditions, as this sensor monitors engine speed and position critical for ignition timing. Camshaft sensor issues often cause rough idling and poor acceleration due to incorrect timing of fuel injection and valve operation. Utilizing diagnostic trouble codes (DTCs) from an OBD-II scanner can help differentiate sensor faults and pinpoint whether the crankshaft or camshaft sensor is malfunctioning.

Repair and Replacement Costs Comparison

Crankshaft sensor repair typically costs between $150 and $300, while replacement can range from $200 to $400 depending on vehicle make and labor rates. Camshaft sensor repairs are generally priced slightly higher, averaging $200 to $350 for repair, with replacement costs reaching up to $450 due to more complex sensor positioning. Both sensors are critical for engine timing, but camshaft sensor replacement often requires more labor, increasing overall repair expenses compared to crankshaft sensor issues.

Preventative Maintenance Tips for Engine Sensors

Regularly inspecting and cleaning the crankshaft and camshaft sensors can prevent engine misfires and stalling problems linked to sensor failures. Using diagnostic tools to monitor sensor signals helps detect early signs of wear or malfunction, reducing breakdown risks. Replacing sensors at manufacturer-recommended intervals ensures optimal engine performance and longevity by maintaining accurate timing and fuel injection controls.

Crankshaft sensor issue vs camshaft sensor issue Infographic

cardiffo.com

cardiffo.com