Hydraulic brake failure occurs when brake fluid leaks or loses pressure, causing a loss of braking power and increased stopping distances. Pneumatic brake failure typically results from air leaks or compressor issues, leading to insufficient air pressure and reduced brake responsiveness. While hydraulic systems rely on fluid dynamics for brake function, pneumatic systems depend on compressed air, making diagnosis and repair methods distinct for each.

Table of Comparison

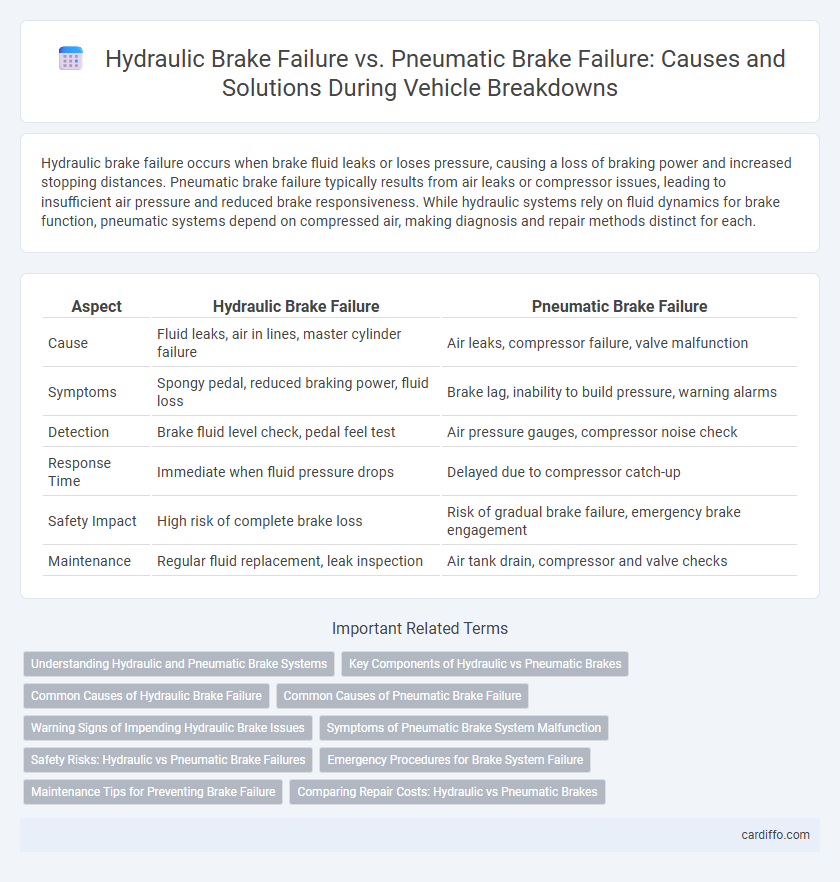

| Aspect | Hydraulic Brake Failure | Pneumatic Brake Failure |

|---|---|---|

| Cause | Fluid leaks, air in lines, master cylinder failure | Air leaks, compressor failure, valve malfunction |

| Symptoms | Spongy pedal, reduced braking power, fluid loss | Brake lag, inability to build pressure, warning alarms |

| Detection | Brake fluid level check, pedal feel test | Air pressure gauges, compressor noise check |

| Response Time | Immediate when fluid pressure drops | Delayed due to compressor catch-up |

| Safety Impact | High risk of complete brake loss | Risk of gradual brake failure, emergency brake engagement |

| Maintenance | Regular fluid replacement, leak inspection | Air tank drain, compressor and valve checks |

Understanding Hydraulic and Pneumatic Brake Systems

Hydraulic brake systems rely on fluid pressure to transmit force from the brake pedal to the brake pads, making them highly responsive and efficient under varying loads. Pneumatic brake systems use compressed air to activate brake mechanisms, providing strong braking power in heavy-duty vehicles and ensuring reliability during extended use. Understanding the operational principles and failure modes of each system is crucial for diagnosing breakdowns and maintaining vehicle safety.

Key Components of Hydraulic vs Pneumatic Brakes

Hydraulic brakes rely on a master cylinder, brake fluid, and calipers to convert pedal pressure into fluid pressure that clamps the brake pads onto the rotors, while pneumatic brakes use compressed air, air compressors, and air chambers to apply force to brake shoes against drums. Key failure points in hydraulic systems include fluid leaks and master cylinder malfunctions, whereas pneumatic systems commonly face issues like air leaks or compressor failures. Understanding these critical components helps diagnose breakdowns effectively and enhances maintenance strategies for both brake types.

Common Causes of Hydraulic Brake Failure

Hydraulic brake failure commonly results from fluid leaks, air trapped in the brake lines, or worn brake pads causing reduced pressure in the system. Contaminated brake fluid and damaged master cylinders also contribute significantly to the malfunction of hydraulic braking systems. Proper maintenance and timely fluid replacement are essential to prevent these failures and ensure efficient brake performance.

Common Causes of Pneumatic Brake Failure

Common causes of pneumatic brake failure include air leaks in the brake lines, malfunctioning compressors, and faulty air dryers that allow moisture to enter the system. Contaminants in the compressed air or damaged brake chambers can also reduce braking efficiency. Proper maintenance of valves, hoses, and fittings is essential to prevent these issues and ensure reliable pneumatic brake performance.

Warning Signs of Impending Hydraulic Brake Issues

Warning signs of impending hydraulic brake failure include a spongy or soft brake pedal, which indicates air or fluid leaks in the system, and decreased braking power that compromises stopping distance. Visible fluid leaks near the brake lines or master cylinder and a brake warning light illuminated on the dashboard are critical indicators requiring immediate inspection. Regular monitoring of brake fluid levels and responsiveness can prevent complete hydraulic brake system breakdowns and ensure overall vehicle safety.

Symptoms of Pneumatic Brake System Malfunction

Pneumatic brake system malfunction often presents with symptoms such as an unusual drop in air pressure, slow or unresponsive brake application, and audible air leaks near the brake chambers or valves. Drivers may notice prolonged stopping distances, inconsistent brake pedal feel, or warning lights indicating low air reserve. Regular inspection of air compressors, reservoirs, and valves is critical to promptly identify and address these signs of pneumatic brake failure.

Safety Risks: Hydraulic vs Pneumatic Brake Failures

Hydraulic brake failure often results in complete loss of braking force due to fluid leakage or air ingress, posing significant safety risks such as increased stopping distances and potential vehicle control loss. Pneumatic brake failure, commonly caused by air pressure loss or compressor malfunctions, can lead to partial or total brake inoperability, increasing the risk of accidents in heavy-duty vehicles. Understanding the differing failure modes helps prioritize maintenance strategies to mitigate safety hazards associated with both hydraulic and pneumatic brake systems.

Emergency Procedures for Brake System Failure

In the event of hydraulic brake failure, immediately pump the brake pedal to build pressure and use the emergency brake gradually to slow the vehicle while steering cautiously. For pneumatic brake failure, rapidly release the tractor protection valve to activate emergency brakes and bring the vehicle to a controlled stop using the parking brake. Both cases require shifting to a lower gear and alerting other drivers with hazard signals to ensure safety during the breakdown.

Maintenance Tips for Preventing Brake Failure

Regular inspection and maintenance of hydraulic brake fluid levels, hoses, and seals are crucial for preventing hydraulic brake failure, as leaks or contaminated fluid can reduce braking efficiency. Pneumatic brake systems require routine checks for air leaks, compressor performance, and moisture drainage to avoid pressure loss and ensure reliable brake response. Consistent upkeep according to manufacturer guidelines significantly reduces the risk of both hydraulic and pneumatic brake failures, enhancing overall vehicle safety and performance.

Comparing Repair Costs: Hydraulic vs Pneumatic Brakes

Repair costs for hydraulic brakes tend to be higher due to the complexity of fluid replacement, sealing, and potential component machining, whereas pneumatic brake repairs often involve air system diagnostics, compressor maintenance, and hose replacements which can be more economical. Hydraulic systems typically require specialized fluids and precision parts, increasing parts and labor expenses compared to pneumatic systems that use compressed air and standard fittings. Overall, pneumatic brake repairs generally incur lower costs and shorter downtime than hydraulic brake failures, making them more cost-effective for heavy-duty vehicle maintenance.

Hydraulic brake failure vs pneumatic brake failure Infographic

cardiffo.com

cardiffo.com