A starter motor issue prevents the engine from turning over, resulting in no sound or a single click when attempting to start the vehicle. Conversely, an ignition coil problem allows the engine to crank but fails to ignite the fuel-air mixture, causing repeated starting attempts without engine ignition. Diagnosing these distinct symptoms helps pinpoint whether the starter motor or ignition coil is the root cause of a breakdown.

Table of Comparison

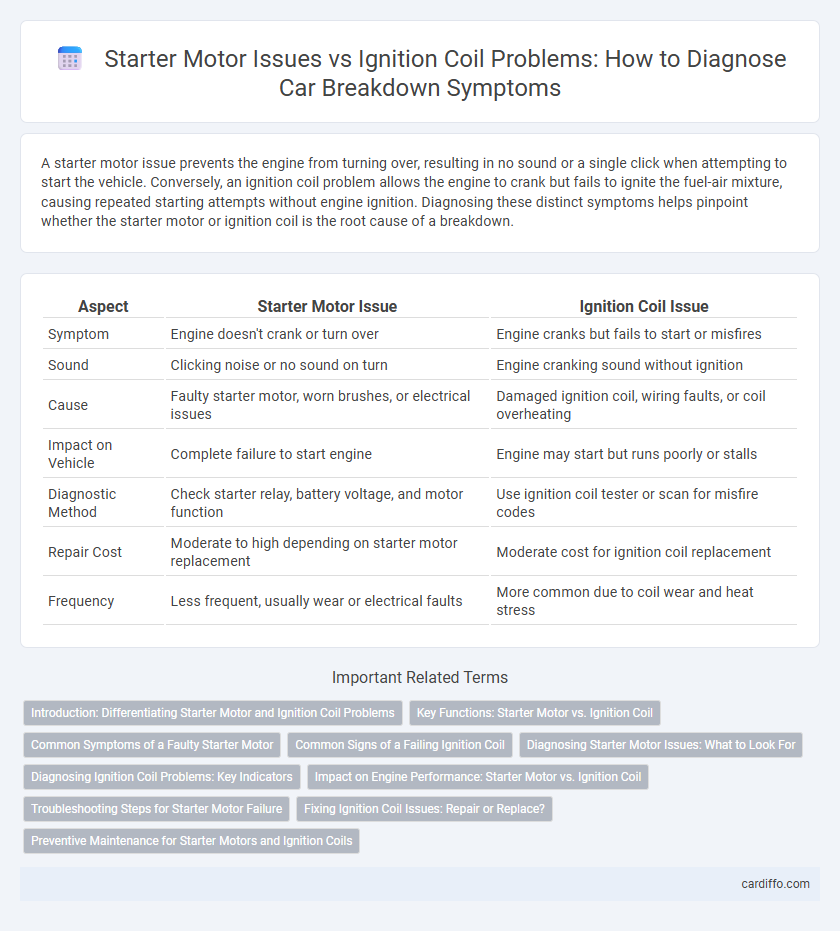

| Aspect | Starter Motor Issue | Ignition Coil Issue |

|---|---|---|

| Symptom | Engine doesn't crank or turn over | Engine cranks but fails to start or misfires |

| Sound | Clicking noise or no sound on turn | Engine cranking sound without ignition |

| Cause | Faulty starter motor, worn brushes, or electrical issues | Damaged ignition coil, wiring faults, or coil overheating |

| Impact on Vehicle | Complete failure to start engine | Engine may start but runs poorly or stalls |

| Diagnostic Method | Check starter relay, battery voltage, and motor function | Use ignition coil tester or scan for misfire codes |

| Repair Cost | Moderate to high depending on starter motor replacement | Moderate cost for ignition coil replacement |

| Frequency | Less frequent, usually wear or electrical faults | More common due to coil wear and heat stress |

Introduction: Differentiating Starter Motor and Ignition Coil Problems

Starter motor issues primarily prevent the engine from turning over, often causing a clicking sound or complete silence when attempting to start the vehicle. Ignition coil problems lead to misfires, poor engine performance, and difficulty igniting the fuel-air mixture in each cylinder. Diagnosing these components accurately ensures timely repairs and prevents further engine damage.

Key Functions: Starter Motor vs. Ignition Coil

The starter motor is responsible for physically rotating the engine to initiate the combustion cycle, while the ignition coil generates the high voltage needed to create a spark in the spark plugs for ignition. A faulty starter motor results in the engine not cranking, leading to a no-start condition without engine turnover. In contrast, a malfunctioning ignition coil can cause misfires, poor fuel efficiency, and engine stalling despite the engine turning over.

Common Symptoms of a Faulty Starter Motor

Common symptoms of a faulty starter motor include a clicking noise when turning the key, a slow or grinding start, and the engine failing to crank despite a fully charged battery. Unlike ignition coil issues that often cause engine misfires or stalling, starter motor problems typically prevent the engine from starting altogether. Recognizing these signs promptly can help avoid extended breakdowns and costly repairs.

Common Signs of a Failing Ignition Coil

Common signs of a failing ignition coil include engine misfires, rough idling, and difficulty starting the vehicle, which can be mistaken for starter motor issues. A faulty ignition coil often causes the check engine light to illuminate and results in poor fuel economy due to incomplete combustion. Unlike starter motor problems, ignition coil failure usually presents with intermittent power loss and backfiring during acceleration.

Diagnosing Starter Motor Issues: What to Look For

Diagnosing starter motor issues involves checking for clicking sounds when turning the key, a lack of engine crank, and dim dashboard lights, indicating insufficient power delivery from the battery or faulty starter motor connections. Inspecting the starter motor, solenoid, and battery terminals for corrosion or loose wiring is essential for accurate identification. Conducting a voltage drop test and tapping the starter motor can further confirm whether the starter motor is failing or if the ignition coil might be the underlying problem.

Diagnosing Ignition Coil Problems: Key Indicators

Diagnosing ignition coil problems involves observing symptoms like engine misfires, rough idling, and difficulty starting the vehicle, which can often be mistaken for starter motor issues. Measuring coil resistance with a multimeter and checking for spark at the spark plugs are key diagnostic steps to confirm ignition coil failure. Ignition coil malfunctions disrupt proper spark generation, leading to performance issues that differ from the mechanical cranking problems typically caused by starter motor faults.

Impact on Engine Performance: Starter Motor vs. Ignition Coil

A faulty starter motor prevents the engine from cranking, leading to complete failure to start, which directly halts engine operation before ignition. In contrast, a malfunctioning ignition coil disrupts spark generation, causing misfires, reduced power, rough idling, and poor fuel efficiency once the engine is running. Both issues impair engine performance but affect different stages of engine operation--starting versus combustion continuity.

Troubleshooting Steps for Starter Motor Failure

Troubleshooting starter motor failure begins with checking the battery voltage to ensure it provides sufficient power, followed by inspecting the starter relay and fuse for continuity. Next, test the starter motor solenoid by measuring resistance or using a bypass method to verify engagement. Finally, examine wiring connections for corrosion or damage, and perform a bench test on the starter motor to confirm mechanical and electrical functionality.

Fixing Ignition Coil Issues: Repair or Replace?

Ignition coil issues often manifest as engine misfires, poor fuel economy, and difficulty starting, signaling the need for prompt attention. Diagnosing whether to repair or replace hinges on the coil's condition, with replacements typically recommended for cracked casings or burnt windings to ensure reliable ignition performance. Professional testing using a multimeter can confirm coil resistance levels, guiding effective repairs and preventing further engine breakdown.

Preventive Maintenance for Starter Motors and Ignition Coils

Preventive maintenance for starter motors involves regular inspection of electrical connections, cleaning of terminals, and testing for voltage drops to ensure reliable engine cranking, while ignition coils require periodic checks for cracks, corrosion, and resistance levels to prevent misfires and starting failures. Early detection of wear or damage in both components through diagnostic testing reduces the risk of unexpected breakdowns and extends the lifespan of the vehicle's ignition system. Implementing scheduled maintenance protocols minimizes the chances of starter motor failure or ignition coil malfunction, enhancing overall vehicle performance and reliability.

Starter motor issue vs ignition coil issue Infographic

cardiffo.com

cardiffo.com