Wheel bearing failure typically causes grinding noises and uneven tire wear due to increased friction, while axle failure often results in vibrations, difficulty steering, and potential loss of vehicle control. Diagnosing the issue involves checking for wheel play or wobbling to identify bearing problems, whereas axle failure is detected by inspecting for visible damage or clicking sounds during turns. Timely repair of either component is crucial to maintain vehicle safety and prevent further mechanical damage.

Table of Comparison

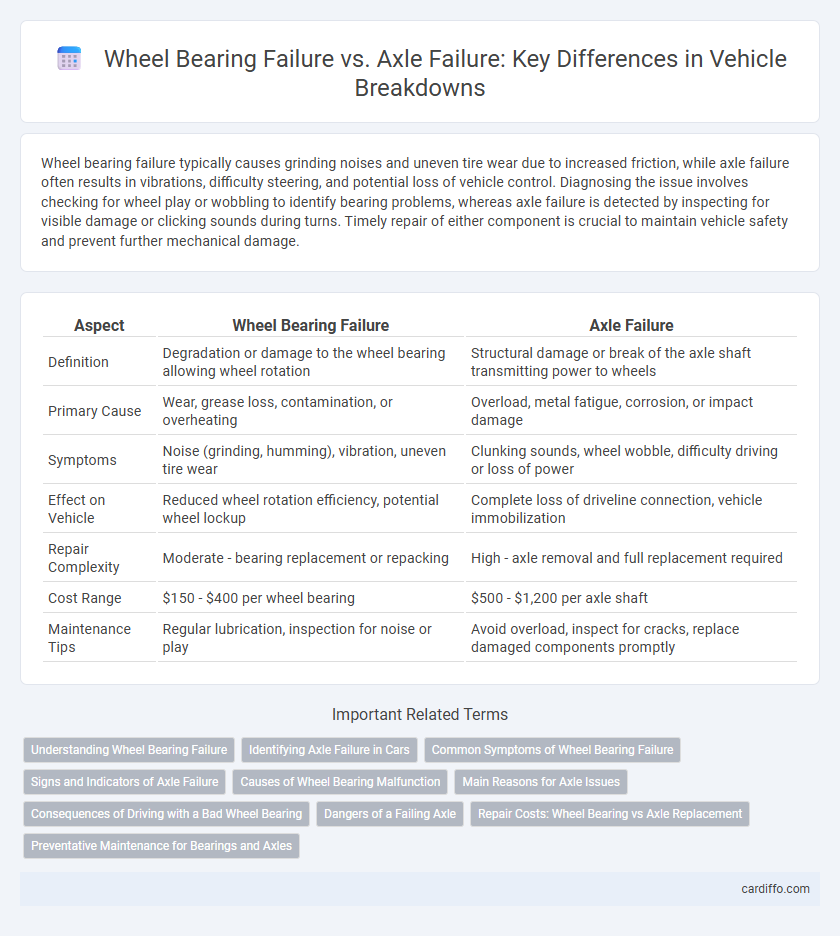

| Aspect | Wheel Bearing Failure | Axle Failure |

|---|---|---|

| Definition | Degradation or damage to the wheel bearing allowing wheel rotation | Structural damage or break of the axle shaft transmitting power to wheels |

| Primary Cause | Wear, grease loss, contamination, or overheating | Overload, metal fatigue, corrosion, or impact damage |

| Symptoms | Noise (grinding, humming), vibration, uneven tire wear | Clunking sounds, wheel wobble, difficulty driving or loss of power |

| Effect on Vehicle | Reduced wheel rotation efficiency, potential wheel lockup | Complete loss of driveline connection, vehicle immobilization |

| Repair Complexity | Moderate - bearing replacement or repacking | High - axle removal and full replacement required |

| Cost Range | $150 - $400 per wheel bearing | $500 - $1,200 per axle shaft |

| Maintenance Tips | Regular lubrication, inspection for noise or play | Avoid overload, inspect for cracks, replace damaged components promptly |

Understanding Wheel Bearing Failure

Wheel bearing failure occurs when the bearing that allows the wheel to rotate smoothly becomes worn or damaged, leading to increased friction, noise, and potential wheel lock-up. Unlike axle failure, which involves structural breakage or bending of the axle shaft, wheel bearing failure primarily affects the rotation and stability of the wheel assembly. Early signs of wheel bearing failure can include humming noises, uneven tire wear, and vibration, emphasizing the importance of timely inspection and replacement to prevent complete breakdown.

Identifying Axle Failure in Cars

Axle failure in cars often manifests through uneven tire wear, vibrations during acceleration, and audible clicking noises when turning. Inspecting the CV joints and axle shafts for cracks, tears, or excessive play can help confirm axle damage. Prompt identification of axle failure prevents complete drivetrain breakdown and ensures vehicle safety.

Common Symptoms of Wheel Bearing Failure

Common symptoms of wheel bearing failure include a humming or growling noise that intensifies with vehicle speed, uneven tire wear, and vibration or wobbling in the steering wheel. Another key indicator is excessive play or looseness in the wheel hub, which can compromise vehicle stability and safety. Unlike axle failure, wheel bearing issues typically present as continuous noise rather than sudden loss of power or complete wheel detachment.

Signs and Indicators of Axle Failure

Axle failure is often indicated by symptoms such as loud clunking noises when shifting gears or turning, excessive vibrations felt through the steering wheel, and visible damage or bending of the axle shaft. Leaking grease around the axle seals and difficulty in maintaining vehicle control also signal axle issues. Unlike wheel bearing failure, axle problems usually result in more severe drivability challenges and potential safety hazards.

Causes of Wheel Bearing Malfunction

Wheel bearing malfunction primarily occurs due to prolonged exposure to contaminants like water, dirt, and debris, which degrade the bearing's lubrication and cause corrosion. Excessive loading, poor installation, and lack of maintenance contribute significantly to premature wear and eventual failure. Unlike axle failure, which often stems from impact damage or metal fatigue, wheel bearing issues are mostly related to lubrication breakdown and environmental factors.

Main Reasons for Axle Issues

Axle failure primarily occurs due to excessive load stress, corrosion, and poor lubrication, which weaken the axle shaft and joints over time. Impact damage from potholes or collisions can cause cracks or bends, compromising the integrity of the axle assembly. Manufacturing defects and lack of timely maintenance further exacerbate wear, leading to premature axle breakdowns.

Consequences of Driving with a Bad Wheel Bearing

Driving with a bad wheel bearing can lead to severe consequences such as increased wheel wobble, uneven tire wear, and compromised vehicle stability, significantly raising the risk of accidents. Unlike axle failure, which often results in immediate loss of vehicle control, a failing wheel bearing gradually degrades performance but can ultimately cause the wheel to lock up or detach if left unaddressed. Prompt repair of wheel bearings is critical to maintaining safe handling, preventing costly damage to suspension components, and avoiding unsafe breakdowns on the road.

Dangers of a Failing Axle

A failing axle poses significant dangers, including sudden loss of vehicle control and potential wheel detachment, which can cause severe accidents. Unlike wheel bearing failure, which often presents gradual symptoms like noise and vibration, axle failure can occur abruptly without warning. Immediate damage to the drivetrain and suspension components further increases repair costs and risks to driver safety.

Repair Costs: Wheel Bearing vs Axle Replacement

Wheel bearing replacement typically costs between $150 and $400, depending on the vehicle make and model, while axle replacement ranges from $300 to $1,000 or more due to increased labor and parts complexity. Wheel bearing repairs generally involve less labor time, averaging one to two hours, whereas axle replacements can take two to four hours or longer, impacting total repair costs. Proper diagnosis is crucial since misidentifying a wheel bearing failure as an axle issue may lead to unnecessary expenses.

Preventative Maintenance for Bearings and Axles

Regular inspection and lubrication of wheel bearings significantly reduce the risk of failure by minimizing friction and wear. Implementing a scheduled maintenance program, including axle alignment checks and load assessments, helps detect early signs of axle fatigue or damage. Prioritizing these preventative measures extends component lifespan and prevents costly breakdowns.

Wheel bearing failure vs axle failure Infographic

cardiffo.com

cardiffo.com