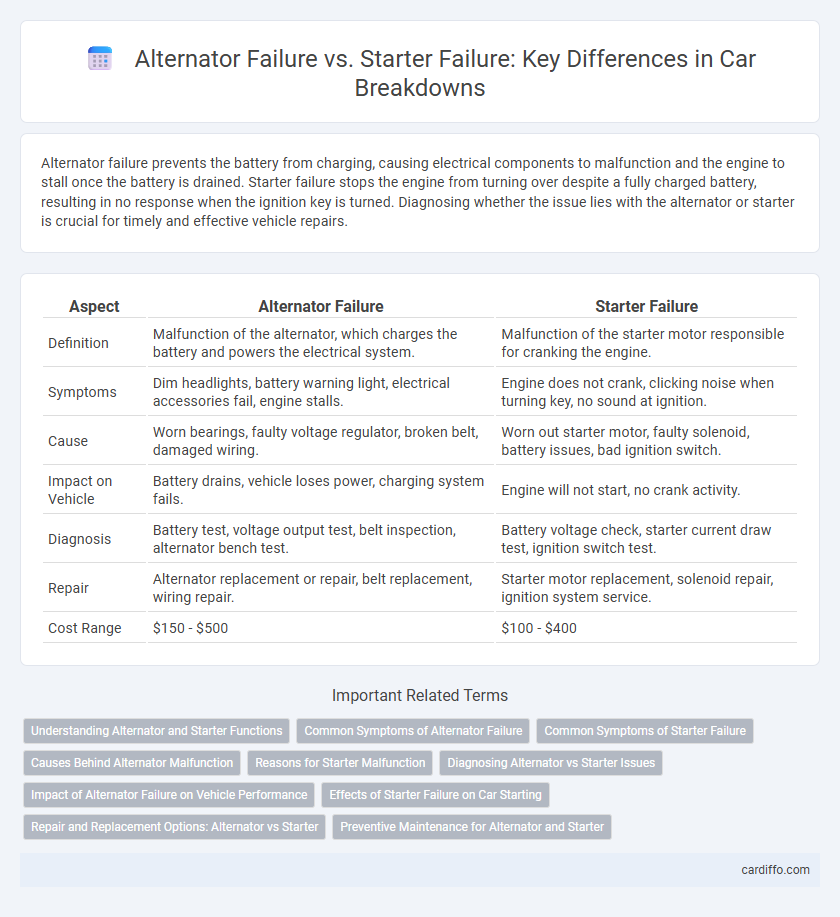

Alternator failure prevents the battery from charging, causing electrical components to malfunction and the engine to stall once the battery is drained. Starter failure stops the engine from turning over despite a fully charged battery, resulting in no response when the ignition key is turned. Diagnosing whether the issue lies with the alternator or starter is crucial for timely and effective vehicle repairs.

Table of Comparison

| Aspect | Alternator Failure | Starter Failure |

|---|---|---|

| Definition | Malfunction of the alternator, which charges the battery and powers the electrical system. | Malfunction of the starter motor responsible for cranking the engine. |

| Symptoms | Dim headlights, battery warning light, electrical accessories fail, engine stalls. | Engine does not crank, clicking noise when turning key, no sound at ignition. |

| Cause | Worn bearings, faulty voltage regulator, broken belt, damaged wiring. | Worn out starter motor, faulty solenoid, battery issues, bad ignition switch. |

| Impact on Vehicle | Battery drains, vehicle loses power, charging system fails. | Engine will not start, no crank activity. |

| Diagnosis | Battery test, voltage output test, belt inspection, alternator bench test. | Battery voltage check, starter current draw test, ignition switch test. |

| Repair | Alternator replacement or repair, belt replacement, wiring repair. | Starter motor replacement, solenoid repair, ignition system service. |

| Cost Range | $150 - $500 | $100 - $400 |

Understanding Alternator and Starter Functions

An alternator converts mechanical energy into electrical energy, supplying power to the vehicle's electrical system and charging the battery while the engine runs. A starter motor uses electrical energy from the battery to crank the engine during ignition, enabling it to start. Alternator failure often results in dimming lights and a dead battery over time, whereas starter failure leads to an inability to start the engine despite a fully charged battery.

Common Symptoms of Alternator Failure

Common symptoms of alternator failure include dim or flickering headlights, a dead battery, and unusual whining or grinding noises from the engine area. Electrical components such as dashboard lights, power windows, and radio may operate intermittently or stop functioning altogether. Frequent stalling or difficulty starting the vehicle also indicate a failing alternator compromising the battery's charge.

Common Symptoms of Starter Failure

Common symptoms of starter failure include a clicking noise when turning the key, a slow or no engine crank, and dim dashboard lights despite a charged battery. Vehicles may also experience intermittent starting issues or complete engine non-response, indicating the starter motor or solenoid is malfunctioning. Identifying these symptoms early helps distinguish starter failure from alternator problems, which typically involve battery drainage and electrical system malfunctions.

Causes Behind Alternator Malfunction

Alternator failure commonly results from worn-out brushes, a faulty voltage regulator, or a broken belt disrupting power generation within the vehicle's electrical system. Excessive heat and corrosion can deteriorate internal components, leading to insufficient battery charging and electrical malfunctions. Unlike starter failure, which often stems from mechanical issues or solenoid faults, alternator malfunction primarily affects the continuous supply of electricity while the engine runs.

Reasons for Starter Malfunction

Starter malfunction primarily occurs due to electrical issues such as a dead battery, corroded battery terminals, or faulty wiring that prevents sufficient current flow. Wear and tear on the starter motor components, including the solenoid or brushes, can also cause failure by hindering the motor's ability to engage with the engine flywheel. Additionally, mechanical problems like a stuck starter gear or damaged flywheel teeth contribute to starter failure, leading to unsuccessful engine cranking.

Diagnosing Alternator vs Starter Issues

Diagnosing alternator failure involves checking for dimming headlights, battery warning lights, and measuring voltage output, which should be between 13.5 to 14.5 volts when the engine runs. Starter failure is identified by symptoms such as a clicking noise when turning the key, no engine turnover, and testing the starter motor's electrical connections with a multimeter. Proper diagnosis differentiates alternator vs starter issues by focusing on electrical output and engine ignition response.

Impact of Alternator Failure on Vehicle Performance

Alternator failure causes the vehicle's battery to lose charge rapidly, leading to dimming headlights, malfunctioning electrical systems, and ultimately engine stalling. Unlike starter failure, which prevents the engine from starting, alternator failure impacts vehicle performance during operation by disrupting power supply to essential components. Continuous alternator issues can result in complete electrical system shutdown, compromising vehicle safety and reliability.

Effects of Starter Failure on Car Starting

Starter failure prevents the engine from cranking, making it impossible to start the vehicle despite a fully charged battery. Symptoms include a clicking sound when turning the key or complete silence, indicating the starter motor is not engaging. Unlike alternator failure, starter failure directly halts engine ignition, requiring starter motor repair or replacement to restore normal vehicle operation.

Repair and Replacement Options: Alternator vs Starter

Alternator failure typically requires either repairing the voltage regulator or replacing the entire alternator assembly, while starter failure often involves replacing the starter motor or solenoid. Repair options for alternators include rebuilding components to restore charging capabilities, whereas starter repairs focus on refurbishing the drive gear or electrical contacts. Both replacements demand precise diagnostics to ensure the correct part is addressed, optimizing vehicle restart and electrical system functionality.

Preventive Maintenance for Alternator and Starter

Regular preventive maintenance of the alternator includes checking belt tension, inspecting electrical connections, and testing voltage output to avoid unexpected failure and vehicle breakdowns. For the starter, routine inspection of the solenoid, cleaning terminals, and ensuring proper battery voltage can prevent starter malfunction and ensure reliable engine ignition. Implementing scheduled maintenance reduces the risk of costly repairs and extends the lifespan of both alternator and starter components.

Alternator Failure vs Starter Failure Infographic

cardiffo.com

cardiffo.com