Proper torque specification ensures bolts are tightened to the manufacturer's recommended force, preventing damage and ensuring safety, whereas hand tightening often results in inconsistent pressure and can lead to loosening or over-tightening. Using a calibrated torque wrench guarantees accurate clamping force, which is critical for reliability and longevity of mechanical assemblies. Ignoring torque specs and relying solely on hand tightness risks component failure and costly repairs.

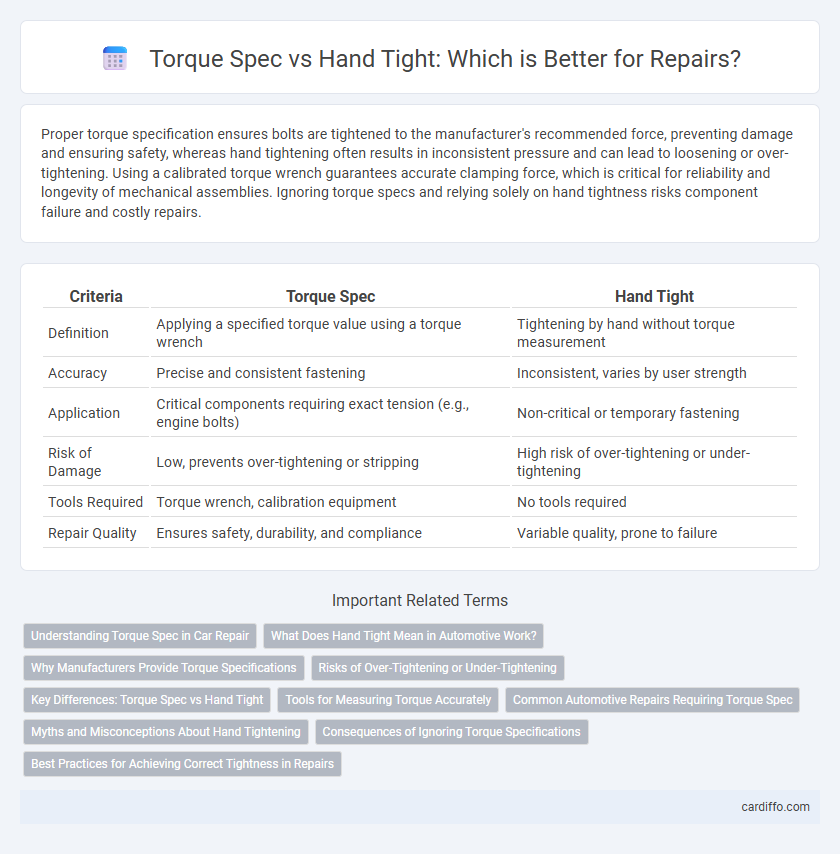

Table of Comparison

| Criteria | Torque Spec | Hand Tight |

|---|---|---|

| Definition | Applying a specified torque value using a torque wrench | Tightening by hand without torque measurement |

| Accuracy | Precise and consistent fastening | Inconsistent, varies by user strength |

| Application | Critical components requiring exact tension (e.g., engine bolts) | Non-critical or temporary fastening |

| Risk of Damage | Low, prevents over-tightening or stripping | High risk of over-tightening or under-tightening |

| Tools Required | Torque wrench, calibration equipment | No tools required |

| Repair Quality | Ensures safety, durability, and compliance | Variable quality, prone to failure |

Understanding Torque Spec in Car Repair

Torque specs provide precise measurements for tightening bolts to ensure proper clamping force without causing damage, critical in automotive repair to maintain safety and component integrity. Hand-tight tightening lacks consistency and can either leave fasteners too loose or damage threads, leading to potential failures. Understanding and applying torque specifications with a calibrated torque wrench enhances reliability and longevity of vehicle repairs.

What Does Hand Tight Mean in Automotive Work?

Hand tight in automotive work means tightening a bolt or nut using only hand force, without tools, to ensure initial secure positioning before applying torque specifications. It prevents over-tightening and potential damage to components, serving as a preliminary step to achieve proper clamping force with a torque wrench. Understanding hand tight versus torque specs is critical for maintaining vehicle safety and mechanical integrity.

Why Manufacturers Provide Torque Specifications

Manufacturers provide torque specifications to ensure fasteners are tightened to the precise level required for optimal performance and safety, preventing damage from over-tightening or loosening due to under-tightening. Proper torque application maintains the integrity of mechanical joints, reduces wear, and avoids costly repairs caused by thread stripping or component deformation. Using a calibrated torque wrench helps achieve these exact specifications, ensuring reliable and durable repairs.

Risks of Over-Tightening or Under-Tightening

Over-tightening fasteners beyond the specified torque can cause thread stripping, bolt stretching, or component damage, compromising the repair's structural integrity. Under-tightening can lead to joint loosening, leaks, or mechanical failure due to insufficient clamping force. Adhering to manufacturer torque specifications is crucial to ensure safety, performance, and longevity of repaired assemblies.

Key Differences: Torque Spec vs Hand Tight

Torque spec ensures fasteners are tightened to a precise value measured in Nm or ft-lbs, preventing under- or over-tightening that can cause damage or failure. Hand tight relies on the technician's feel and may lead to inconsistent clamping force, increasing the risk of parts loosening or warping. Using torque spec is critical for maintaining safety, reliability, and manufacturer warranty compliance in repair procedures.

Tools for Measuring Torque Accurately

Precision torque wrenches are essential tools for measuring torque accurately, ensuring bolts are tightened to the manufacturer's specified torque specs and preventing over- or under-tightening damage. Digital torque meters offer real-time, highly accurate readings, making them ideal for critical repairs requiring exact torque application. Using calibrated mechanical torque wrenches guarantees consistency and reliability in hand-tightening tasks, reducing the risk of component failure.

Common Automotive Repairs Requiring Torque Spec

Common automotive repairs requiring torque specs include cylinder head bolts, lug nuts, and suspension components to ensure proper clamping force and prevent damage or failure. Using a torque wrench guarantees accurate tightening according to manufacturer specifications, maintaining vehicle safety and performance. Relying solely on hand tight can lead to under-tightening or over-tightening, increasing the risk of part wear or unexpected breakdowns.

Myths and Misconceptions About Hand Tightening

Hand tightening is often misunderstood as sufficient for securing fasteners, but it rarely achieves the precise torque specifications required for optimal performance and safety. Myths surrounding hand tightening ignore the variability in grip strength and the critical role of torque specs in preventing over- or under-tightening, which can lead to mechanical failure or damage. Utilizing calibrated torque tools ensures fasteners meet manufacturer standards, enhancing reliability and longevity in repair applications.

Consequences of Ignoring Torque Specifications

Ignoring torque specifications during repairs can lead to severe consequences such as stripped threads, warped components, and compromised structural integrity. Over-tightening bolts risks material fatigue and potential part failure, while under-tightening causes loose fittings, vibration, and accelerated wear. Adhering to manufacturer-recommended torque values ensures optimal performance and safety, preventing costly repairs and hazardous malfunctions.

Best Practices for Achieving Correct Tightness in Repairs

Achieving correct tightness in repairs demands adherence to torque specifications rather than relying on hand tight methods, as torque specs provide precise measurements tailored to fastener material and size. Using a calibrated torque wrench ensures consistent application of the manufacturer's recommended torque value, preventing under-tightening or over-tightening that can lead to component failure or damage. Best practices include verifying torque wrench calibration, following repair manuals closely, and allowing appropriate relaxation intervals for thread compounds or lubrication during assembly.

Torque Spec vs Hand Tight Infographic

cardiffo.com

cardiffo.com