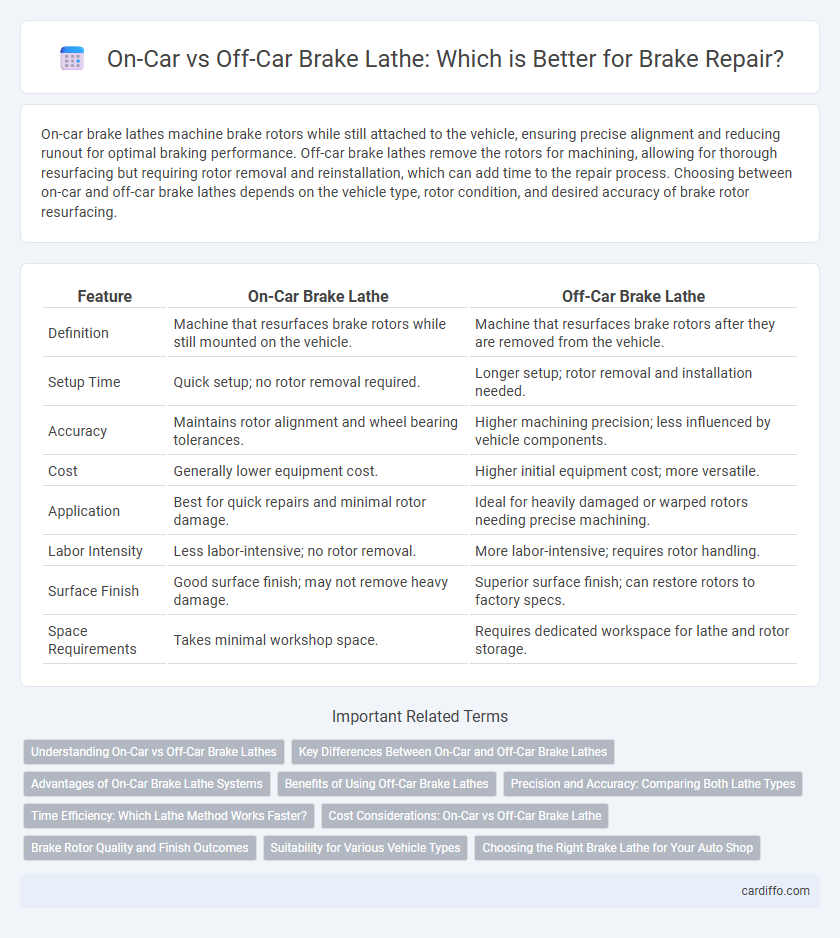

On-car brake lathes machine brake rotors while still attached to the vehicle, ensuring precise alignment and reducing runout for optimal braking performance. Off-car brake lathes remove the rotors for machining, allowing for thorough resurfacing but requiring rotor removal and reinstallation, which can add time to the repair process. Choosing between on-car and off-car brake lathes depends on the vehicle type, rotor condition, and desired accuracy of brake rotor resurfacing.

Table of Comparison

| Feature | On-Car Brake Lathe | Off-Car Brake Lathe |

|---|---|---|

| Definition | Machine that resurfaces brake rotors while still mounted on the vehicle. | Machine that resurfaces brake rotors after they are removed from the vehicle. |

| Setup Time | Quick setup; no rotor removal required. | Longer setup; rotor removal and installation needed. |

| Accuracy | Maintains rotor alignment and wheel bearing tolerances. | Higher machining precision; less influenced by vehicle components. |

| Cost | Generally lower equipment cost. | Higher initial equipment cost; more versatile. |

| Application | Best for quick repairs and minimal rotor damage. | Ideal for heavily damaged or warped rotors needing precise machining. |

| Labor Intensity | Less labor-intensive; no rotor removal. | More labor-intensive; requires rotor handling. |

| Surface Finish | Good surface finish; may not remove heavy damage. | Superior surface finish; can restore rotors to factory specs. |

| Space Requirements | Takes minimal workshop space. | Requires dedicated workspace for lathe and rotor storage. |

Understanding On-Car vs Off-Car Brake Lathes

On-car brake lathes enable technicians to resurface brake rotors directly on the vehicle, preserving rotor alignment and reducing installation time. Off-car brake lathes require removing the rotor for resurfacing, often providing more precise material removal and the ability to address severe rotor damage. Understanding the differences in application, accuracy, and time efficiency helps in selecting the appropriate brake lathe for vehicle maintenance and repair.

Key Differences Between On-Car and Off-Car Brake Lathes

On-car brake lathes machine the brake rotors while still mounted on the vehicle, preserving alignment and minimizing the risk of rotor runout. Off-car brake lathes require rotor removal, offering precision machining with controlled setup but adding labor time for rotor removal and reinstallation. Key differences include on-car lathes providing quick, alignment-preserving resurfacing ideal for minor brake pulse issues, while off-car lathes allow comprehensive rotor resurfacing for significant damage or wear, ensuring optimal rotor thickness and surface finish.

Advantages of On-Car Brake Lathe Systems

On-car brake lathe systems provide precise braking surface restoration by machining rotor or drum directly on the vehicle, reducing alignment errors caused by rotor removal. This method preserves concentricity and wheel alignment, leading to improved brake performance and extended rotor life. On-car lathes also minimize labor time and costs associated with disassembling brake components, enhancing overall repair efficiency.

Benefits of Using Off-Car Brake Lathes

Off-car brake lathes provide precise rotor resurfacing by allowing the technician to remove the rotor from the vehicle, eliminating the risk of spindle runout that can occur with on-car machines. This method ensures consistent, high-quality brake rotor refinishing by maintaining optimal surface flatness and parallelism, leading to improved braking performance and reduced vibration. Off-car lathes also offer versatility for resurfacing rotors from multiple vehicle types, enhancing repair shop efficiency and customer satisfaction.

Precision and Accuracy: Comparing Both Lathe Types

On-car brake lathes offer enhanced precision by machining the brake rotor directly on the vehicle, ensuring true alignment with the hub and minimizing runout. Off-car brake lathes provide high accuracy through controlled, stationary setups that allow for uniform material removal and customizable cutting parameters. Both types achieve precise rotor resurfacing, but on-car lathes excel in maintaining factory-level alignment, while off-car lathes offer superior control over surface finish and dimensional tolerances.

Time Efficiency: Which Lathe Method Works Faster?

On-car brake lathes provide significant time efficiency by machining the brake rotors directly on the vehicle, eliminating the need to remove, transport, and remount the rotors. Off-car brake lathes require rotor removal and setup, which adds labor time and increases the overall brake service duration. Technicians seeking faster turnaround often prefer on-car lathes due to reduced handling and quicker precision resurfacing.

Cost Considerations: On-Car vs Off-Car Brake Lathe

On-car brake lathes generally reduce labor costs by machining the brake rotor while still mounted on the vehicle, eliminating the need for rotor removal and reinstallation. Off-car brake lathes require rotor removal, increasing labor time and potential shop downtime, but often provide more precise machining and are better suited for high-volume repair shops. The initial investment for on-car lathes can be higher, but long-term operational savings often outweigh these costs compared to off-car lathe setups.

Brake Rotor Quality and Finish Outcomes

On-car brake lathes provide precise rotor resurfacing by machining the brake rotor directly on the vehicle, preserving factory runout and alignment for improved brake rotor quality and finish outcomes. Off-car brake lathes allow removal and resurfacing of rotors separately, offering more controlled machining environments but risking potential misalignment and inconsistent finish due to rotor handling. Brake rotor quality from on-car lathes generally results in lower vibration and better surface smoothness, enhancing braking performance and longevity compared to off-car lathe refinishing.

Suitability for Various Vehicle Types

On-car brake lathes are ideal for high-performance and heavy-duty vehicles requiring precise rotor machining without removal, preserving rotor alignment. Off-car brake lathes suit a wider range of vehicle types, offering versatility for standard passenger cars, trucks, and fleet vehicles by enabling rotors to be machined separately. Technicians select the lathe type based on vehicle weight, rotor size, and desired machining accuracy to optimize brake system performance.

Choosing the Right Brake Lathe for Your Auto Shop

Choosing the right brake lathe for your auto shop depends on the volume of work and precision required, with on-car brake lathes offering the advantage of machining rotors directly without removal, reducing labor time and potential errors. Off-car brake lathes provide greater versatility and precision for a wider range of rotor types and sizes, ideal for shops handling diverse vehicles and requiring consistent, high-quality resurfacing. Assessing shop workflow, vehicle types serviced, and budget constraints ensures the selection enhances productivity and brake repair quality.

on-car brake lathe vs off-car brake lathe Infographic

cardiffo.com

cardiffo.com