Pushrod engines use a simpler design with lifters and pushrods to operate the valves, offering durability and easier maintenance. Overhead cam (OHC) engines place the camshaft above the valves, allowing for more precise timing and higher RPM potential. Choosing between pushrod and overhead cam depends on priorities like performance, efficiency, and mechanical complexity.

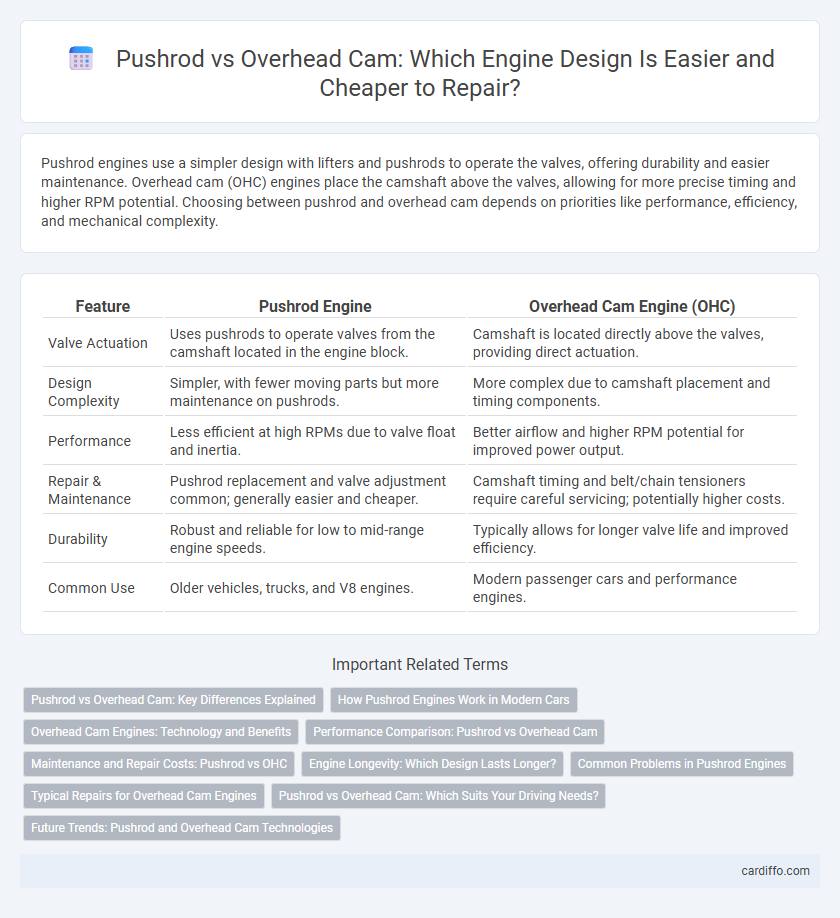

Table of Comparison

| Feature | Pushrod Engine | Overhead Cam Engine (OHC) |

|---|---|---|

| Valve Actuation | Uses pushrods to operate valves from the camshaft located in the engine block. | Camshaft is located directly above the valves, providing direct actuation. |

| Design Complexity | Simpler, with fewer moving parts but more maintenance on pushrods. | More complex due to camshaft placement and timing components. |

| Performance | Less efficient at high RPMs due to valve float and inertia. | Better airflow and higher RPM potential for improved power output. |

| Repair & Maintenance | Pushrod replacement and valve adjustment common; generally easier and cheaper. | Camshaft timing and belt/chain tensioners require careful servicing; potentially higher costs. |

| Durability | Robust and reliable for low to mid-range engine speeds. | Typically allows for longer valve life and improved efficiency. |

| Common Use | Older vehicles, trucks, and V8 engines. | Modern passenger cars and performance engines. |

Pushrod vs Overhead Cam: Key Differences Explained

Pushrod and overhead cam (OHC) engines differ primarily in valve train design; pushrod engines use lifters and pushrods to actuate valves from a camshaft located in the engine block, while overhead cam engines position the camshafts directly above the valves. Pushrod engines typically offer a more compact design and lower manufacturing costs but often have less precise valve timing and reduced high-RPM performance compared to overhead cam systems. Overhead cam engines provide improved efficiency, higher engine speeds, and better power output due to more direct valve actuation and reduced valvetrain mass.

How Pushrod Engines Work in Modern Cars

Pushrod engines in modern cars operate by using a camshaft located within the engine block to move pushrods upward, which then activate the rocker arms to open and close the valves. This design allows for a more compact engine layout and typically results in increased low-end torque, making pushrod engines particularly effective for trucks and muscle cars. Despite the rise of overhead camshaft systems, pushrod engines remain favored for their durability and simpler repair process in performance and heavy-duty applications.

Overhead Cam Engines: Technology and Benefits

Overhead cam (OHC) engines utilize camshafts located above the cylinder head, enabling more precise valve timing and improved engine efficiency compared to pushrod designs. This technology reduces valve train mass and allows higher engine speeds, enhancing performance and fuel economy. Enhanced airflow and reduced mechanical complexity contribute to lower emissions and increased engine longevity, making OHC systems a preferred choice in modern vehicle repairs.

Performance Comparison: Pushrod vs Overhead Cam

Pushrod engines typically offer a more compact design with fewer moving parts, resulting in lower manufacturing costs and improved low-end torque, making them suitable for applications requiring strong initial acceleration. Overhead cam (OHC) engines provide better high-RPM performance due to more precise valve timing and reduced valvetrain inertia, which enhances airflow efficiency and overall horsepower. Performance comparison reveals OHC designs generally deliver superior peak power and fuel efficiency, while pushrod engines excel in durability and torque at lower engine speeds.

Maintenance and Repair Costs: Pushrod vs OHC

Pushrod engines typically have fewer moving parts, leading to lower maintenance and repair costs compared to overhead cam (OHC) engines, which feature more complex valve train components that can increase service expenses. Overhead cam engines often require specialized tools and expertise for timing belt or chain replacements, making repairs more time-consuming and costly. Routine valve adjustments are generally simpler and less frequent in pushrod systems, contributing to their cost-effectiveness in long-term maintenance.

Engine Longevity: Which Design Lasts Longer?

Pushrod engines generally offer greater engine longevity due to their simpler design with fewer moving parts, reducing wear and potential failure points. Overhead cam (OHC) engines, while providing better performance and efficiency, often experience more stress on timing components, potentially leading to earlier maintenance issues. Regular maintenance and quality materials are critical factors influencing the durability of both pushrod and overhead cam engine designs.

Common Problems in Pushrod Engines

Pushrod engines often face common problems such as valve train wear and improper valve timing due to the longer pushrod mechanism, which can lead to decreased engine performance and increased maintenance costs. Excessive play in the pushrod or worn rocker arms can cause noisy operation and reduced efficiency, necessitating frequent adjustments and inspections. Compared to overhead cam engines, pushrod designs are more prone to mechanical issues stemming from their complex valvetrain geometry and higher mechanical stress on components.

Typical Repairs for Overhead Cam Engines

Typical repairs for overhead cam engines often involve replacing worn timing belts or chains, adjusting camshaft timing, and addressing valve seal or gasket failures. Overhead cam designs require precise timing alignment, making camshaft sensor replacement and valve clearance adjustments common maintenance tasks. Repair technicians must also monitor for oil leaks around camshaft seals and ensure proper lubrication to prevent premature wear.

Pushrod vs Overhead Cam: Which Suits Your Driving Needs?

Pushrod engines offer a compact design with fewer moving parts, making them ideal for low-end torque and simple repairs, while overhead cam (OHC) engines provide higher RPM efficiency and better fuel economy suited for performance-oriented driving. Choosing between pushrod and overhead cam designs depends on your driving preferences: pushrod engines excel in durability and towing power, whereas OHC engines deliver smoother operation and advanced valve timing for a refined driving experience. Understanding these key differences helps drivers select an engine type aligned with their maintenance capabilities and performance expectations.

Future Trends: Pushrod and Overhead Cam Technologies

Future trends in pushrod and overhead cam (OHC) technologies emphasize increasing efficiency and performance through advanced materials and precision engineering. Pushrod engines are evolving with lightweight alloys and improved valvetrain designs to enhance durability and fuel economy in compact applications. OHC systems benefit from variable valve timing and electrification, driving innovations that support stricter emissions standards and hybrid powertrain integration.

Pushrod vs Overhead Cam Infographic

cardiffo.com

cardiffo.com