Soldering wires creates a strong, conductive bond ideal for permanent repairs, ensuring minimal resistance and lasting durability in pet repair projects. Crimping wires offers a quicker, mechanical connection that requires no heat, making it suitable for flexible joints or temporary fixes. Selecting between soldering and crimping depends on the specific pet repair's need for strength, conductivity, and ease of maintenance.

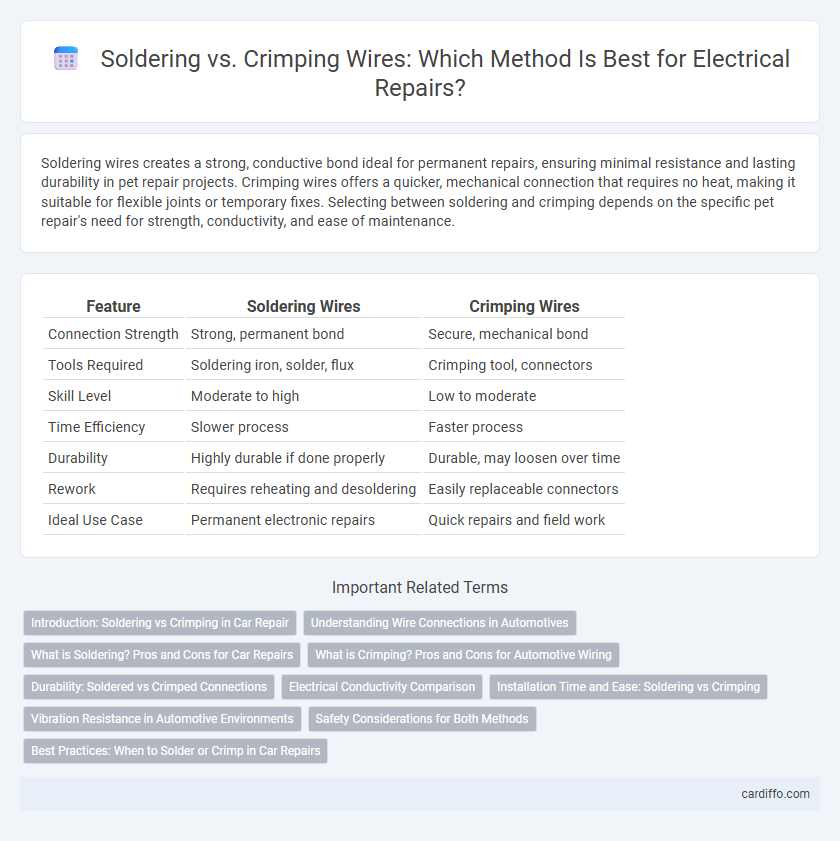

Table of Comparison

| Feature | Soldering Wires | Crimping Wires |

|---|---|---|

| Connection Strength | Strong, permanent bond | Secure, mechanical bond |

| Tools Required | Soldering iron, solder, flux | Crimping tool, connectors |

| Skill Level | Moderate to high | Low to moderate |

| Time Efficiency | Slower process | Faster process |

| Durability | Highly durable if done properly | Durable, may loosen over time |

| Rework | Requires reheating and desoldering | Easily replaceable connectors |

| Ideal Use Case | Permanent electronic repairs | Quick repairs and field work |

Introduction: Soldering vs Crimping in Car Repair

Soldering wires creates a strong, conductive bond by melting metal alloy to join strands, enhancing electrical continuity in car repairs. Crimping wires involves compacting connectors onto wire ends, providing mechanical stability and ease of installation without heat. Choosing between soldering and crimping depends on the specific automotive wiring application and desired durability.

Understanding Wire Connections in Automotives

Soldering wires in automotive repairs provides a strong, conductive, and durable connection that is resistant to corrosion when done correctly with proper flux and heat control. Crimping wires offers a quicker, vibration-resistant mechanical connection ideal for factory-grade reliability and mass production settings, using specialized crimp connectors that ensure consistent pressure. Understanding the balance between soldering's electrical conductivity and crimping's mechanical strength is critical for maintaining optimal wire performance and safety in automotive electrical systems.

What is Soldering? Pros and Cons for Car Repairs

Soldering is the process of joining wires by melting a filler metal (solder) to create a strong electrical and mechanical bond, commonly used in car repairs for precise and durable connections. Pros include excellent conductivity, permanent and corrosion-resistant joints, and suitability for complex or tight spaces in automotive wiring. Cons involve requiring skill and proper tools, longer repair times than crimping, and the risk of heat damage to sensitive car components if not performed correctly.

What is Crimping? Pros and Cons for Automotive Wiring

Crimping is a mechanical method of joining wires using a specialized tool that compresses a metal connector onto the wire, ensuring a secure and reliable electrical connection. In automotive wiring, crimping offers advantages such as faster installation, strong resistance to vibration, and minimal risk of overheating, making it ideal for vehicle environments. However, crimped connections may suffer from corrosion if not properly sealed and require the right tools and connectors to achieve consistent quality.

Durability: Soldered vs Crimped Connections

Soldered connections offer superior electrical conductivity and resistance to corrosion, enhancing long-term durability in high-vibration environments. Crimped connections, when performed with high-quality terminals and tools, provide strong mechanical bonds that resist wire fatigue and loosening over time. Both methods require proper technique to achieve optimal durability, but soldering can be more vulnerable to damage from thermal cycling compared to crimping.

Electrical Conductivity Comparison

Soldering wires creates a strong, low-resistance electrical connection by melting solder to bond metal surfaces, ensuring excellent conductivity with minimal signal loss. Crimping wires relies on mechanical compression to join conductors, which can introduce slight resistance due to potential gaps or oxidation but generally provides reliable conductivity when properly executed. Electrical conductivity in soldered joints typically surpasses crimped connections, making soldering the preferred method for high-performance or sensitive electronic repairs.

Installation Time and Ease: Soldering vs Crimping

Crimping wires significantly reduces installation time compared to soldering, as it eliminates the need for heating and cooling phases, allowing for quicker and more consistent connections. The ease of crimping lies in its straightforward, tool-based process, which requires minimal skill and produces reliable results. Soldering demands more precision and practice, making it slower and often more challenging for less experienced installers.

Vibration Resistance in Automotive Environments

Soldering wires creates a solid, permanent bond that resists corrosion and maintains electrical conductivity under vibration but can become brittle over time in automotive environments. Crimping wires form a mechanical connection that absorbs vibration better by maintaining flexibility and reducing the risk of wire fatigue or breakage. In high-vibration automotive settings, crimped connections generally offer superior durability and long-term reliability compared to soldered joints.

Safety Considerations for Both Methods

Soldering wires provides a durable and conductive connection but requires caution due to the high heat involved, posing risks of burns and potential damage to insulation or nearby components if not handled properly. Crimping wires eliminates heat exposure, reducing burn hazards, but demands using the correct tool and terminals to ensure a secure, reliable connection that prevents electrical shorts or wire loosening. Both methods require appropriate personal protective equipment (PPE) and workspace ventilation to minimize exposure to harmful fumes or sharp wire edges for safe and effective electrical repairs.

Best Practices: When to Solder or Crimp in Car Repairs

Soldering wires provides a strong, conductive, and corrosion-resistant connection ideal for permanent repairs in car electrical systems, especially where vibration and moisture are concerns. Crimping wires offers a faster, reliable, and mechanically robust method preferred for quick repairs and factory-style connections that require consistent tension and resistance to loosening. Best practices recommend soldering critical signal or power lines that demand durability and crimping for harnesses or connectors that benefit from standardized, repeatable assembly in automotive repairs.

Soldering wires vs Crimping wires Infographic

cardiffo.com

cardiffo.com