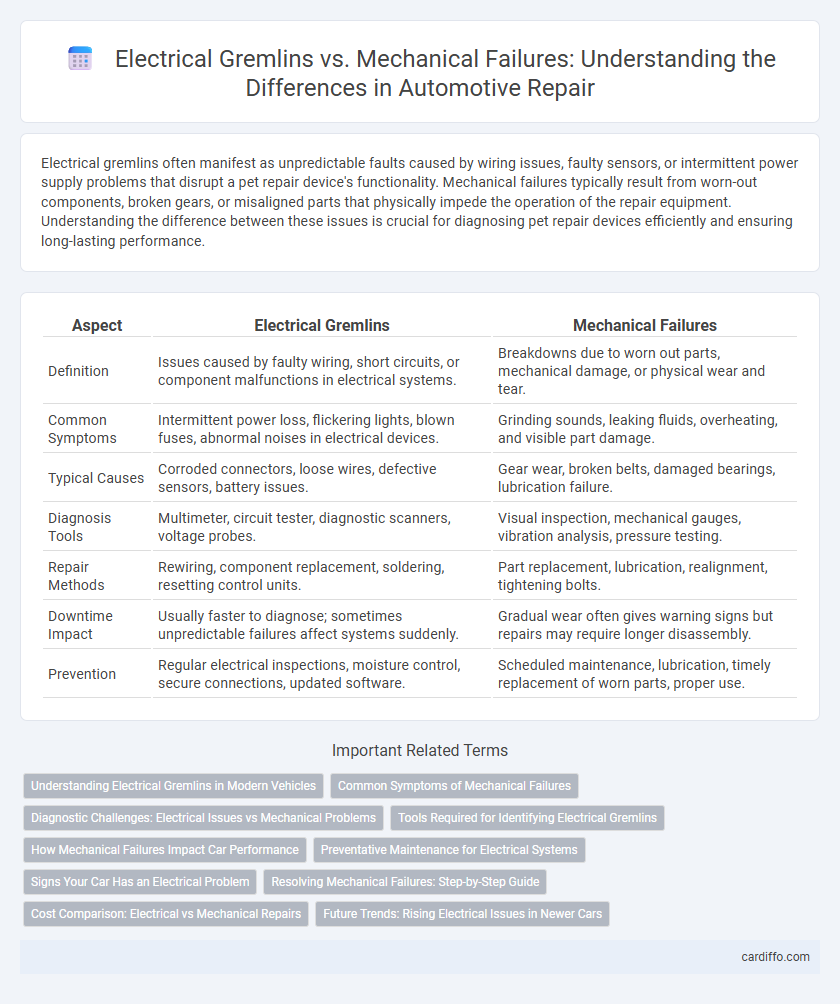

Electrical gremlins often manifest as unpredictable faults caused by wiring issues, faulty sensors, or intermittent power supply problems that disrupt a pet repair device's functionality. Mechanical failures typically result from worn-out components, broken gears, or misaligned parts that physically impede the operation of the repair equipment. Understanding the difference between these issues is crucial for diagnosing pet repair devices efficiently and ensuring long-lasting performance.

Table of Comparison

| Aspect | Electrical Gremlins | Mechanical Failures |

|---|---|---|

| Definition | Issues caused by faulty wiring, short circuits, or component malfunctions in electrical systems. | Breakdowns due to worn out parts, mechanical damage, or physical wear and tear. |

| Common Symptoms | Intermittent power loss, flickering lights, blown fuses, abnormal noises in electrical devices. | Grinding sounds, leaking fluids, overheating, and visible part damage. |

| Typical Causes | Corroded connectors, loose wires, defective sensors, battery issues. | Gear wear, broken belts, damaged bearings, lubrication failure. |

| Diagnosis Tools | Multimeter, circuit tester, diagnostic scanners, voltage probes. | Visual inspection, mechanical gauges, vibration analysis, pressure testing. |

| Repair Methods | Rewiring, component replacement, soldering, resetting control units. | Part replacement, lubrication, realignment, tightening bolts. |

| Downtime Impact | Usually faster to diagnose; sometimes unpredictable failures affect systems suddenly. | Gradual wear often gives warning signs but repairs may require longer disassembly. |

| Prevention | Regular electrical inspections, moisture control, secure connections, updated software. | Scheduled maintenance, lubrication, timely replacement of worn parts, proper use. |

Understanding Electrical Gremlins in Modern Vehicles

Electrical gremlins in modern vehicles often manifest as intermittent faults, such as flickering lights, unresponsive sensors, or malfunctioning infotainment systems, caused by issues like loose wiring, corroded connectors, or software glitches. Diagnosing these problems requires specialized diagnostic tools capable of reading error codes and monitoring real-time sensor data to pinpoint irregularities in the vehicle's electronic control units (ECUs). Understanding the complexity of vehicle electronics systems is crucial for effective troubleshooting and ensuring a seamless repair process that distinguishes electrical gremlins from mechanical failures.

Common Symptoms of Mechanical Failures

Mechanical failures commonly present symptoms such as unusual noises like grinding or clunking, visible wear or damage on parts, and irregular operation including vibrations or stiffness. These issues often result from component fatigue, misalignment, or lubrication breakdown. Identifying these symptoms early helps prevent further damage and ensures timely repair of mechanical systems.

Diagnostic Challenges: Electrical Issues vs Mechanical Problems

Electrical gremlins often manifest as intermittent faults driven by complex wiring faults, sensor malfunctions, or software glitches, making diagnostics reliant on advanced scan tools and wiring diagrams. Mechanical failures typically present more consistently through physical wear, broken components, or lubrication issues, allowing for tactile inspection and straightforward testing methods. Distinguishing between electrical and mechanical causes requires comprehensive diagnostics combining sensor data analysis and physical examination to pinpoint the root cause efficiently.

Tools Required for Identifying Electrical Gremlins

Diagnostic tools essential for identifying electrical gremlins include multimeters, oscilloscopes, and circuit testers, which measure voltage, current, and signal integrity in electrical systems. Thermal imaging cameras help detect overheating components and faulty connections, while specialized software can analyze error codes from vehicle or machinery control units. Proper use of these tools enables precise troubleshooting and effective repair of electrical malfunctions.

How Mechanical Failures Impact Car Performance

Mechanical failures significantly degrade car performance by causing issues such as reduced engine efficiency, compromised braking systems, and faulty suspension components. These failures often result in increased fuel consumption, diminished power output, and unsafe handling characteristics. Timely diagnosis and repair of mechanical faults are essential to maintain optimal vehicle reliability and safety on the road.

Preventative Maintenance for Electrical Systems

Preventative maintenance for electrical systems targets electrical gremlins such as voltage fluctuations, loose connections, and circuit overloads by regularly inspecting wiring, testing components, and ensuring proper insulation. Mechanical failures, often caused by wear and tear of physical parts, are mitigated by lubrication and timely replacement of moving components, but electrical issues require specialized diagnostic tools like multimeters and thermal cameras. Implementing scheduled maintenance protocols reduces downtime, enhances system reliability, and prevents costly repairs related to unforeseen electrical faults.

Signs Your Car Has an Electrical Problem

Flickering dashboard lights, intermittent power loss, and malfunctioning electronic accessories are common signs your car has an electrical problem. Difficulty starting the engine or frequent battery drain also indicate potential electrical gremlins rather than mechanical failures. Diagnosing these issues early can prevent costly repairs and ensure vehicle reliability.

Resolving Mechanical Failures: Step-by-Step Guide

Diagnosing mechanical failures involves a systematic inspection of moving parts, checking for wear, misalignment, or broken components. Begin by isolating the affected mechanism, then use diagnostic tools such as calipers and vibration analyzers to identify faults precisely. Address the issue by cleaning, lubricating, tightening, or replacing defective parts, followed by testing the repair under operational conditions to ensure full functionality.

Cost Comparison: Electrical vs Mechanical Repairs

Electrical repairs often incur higher costs due to the complexity of diagnosing circuit issues and the expensive components involved, such as sensors and control modules. Mechanical failures typically require more labor-intensive work but use fewer costly parts, leading to generally lower repair expenses. Budget planning should consider the variability in parts pricing and labor time, as electrical faults can escalate costs rapidly compared to mechanical repairs.

Future Trends: Rising Electrical Issues in Newer Cars

Future automotive repairs reveal a significant rise in electrical gremlins as newer vehicles increasingly rely on complex electronic systems and advanced software integration. Diagnostic tools are evolving to address intricate electrical failures, emphasizing the need for technicians skilled in both digital and traditional mechanical repair. This trend underscores a shift towards prioritizing electrical system diagnostics and maintenance to ensure vehicle reliability and safety.

Electrical Gremlins vs Mechanical Failures Infographic

cardiffo.com

cardiffo.com