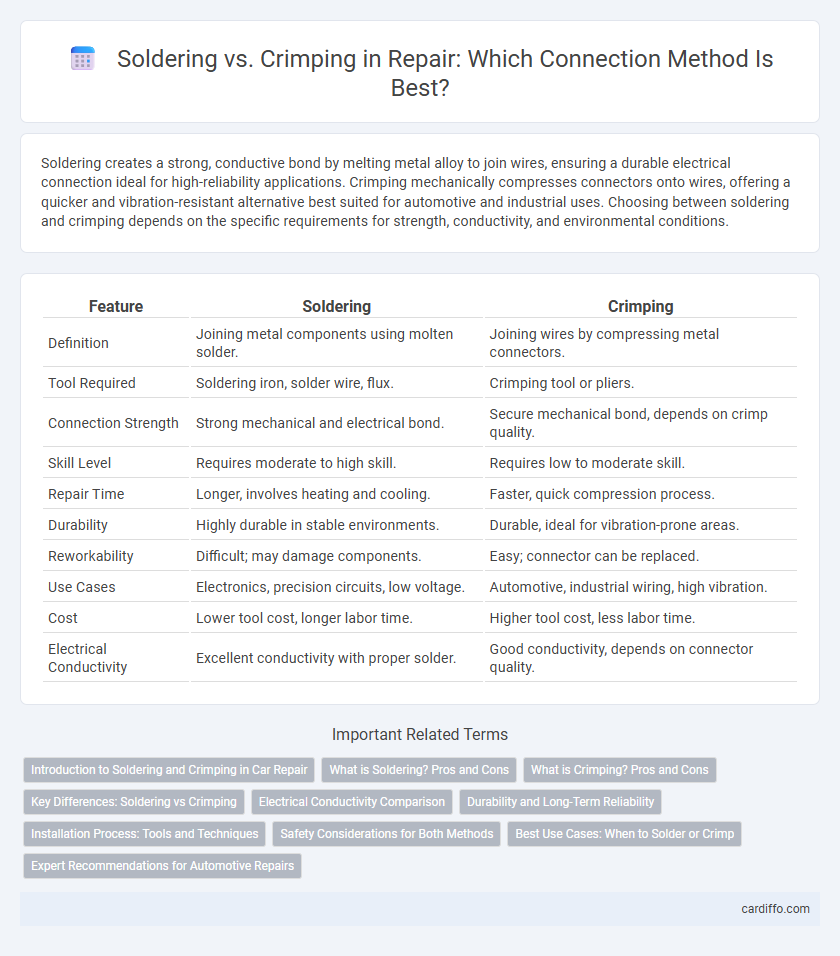

Soldering creates a strong, conductive bond by melting metal alloy to join wires, ensuring a durable electrical connection ideal for high-reliability applications. Crimping mechanically compresses connectors onto wires, offering a quicker and vibration-resistant alternative best suited for automotive and industrial uses. Choosing between soldering and crimping depends on the specific requirements for strength, conductivity, and environmental conditions.

Table of Comparison

| Feature | Soldering | Crimping |

|---|---|---|

| Definition | Joining metal components using molten solder. | Joining wires by compressing metal connectors. |

| Tool Required | Soldering iron, solder wire, flux. | Crimping tool or pliers. |

| Connection Strength | Strong mechanical and electrical bond. | Secure mechanical bond, depends on crimp quality. |

| Skill Level | Requires moderate to high skill. | Requires low to moderate skill. |

| Repair Time | Longer, involves heating and cooling. | Faster, quick compression process. |

| Durability | Highly durable in stable environments. | Durable, ideal for vibration-prone areas. |

| Reworkability | Difficult; may damage components. | Easy; connector can be replaced. |

| Use Cases | Electronics, precision circuits, low voltage. | Automotive, industrial wiring, high vibration. |

| Cost | Lower tool cost, longer labor time. | Higher tool cost, less labor time. |

| Electrical Conductivity | Excellent conductivity with proper solder. | Good conductivity, depends on connector quality. |

Introduction to Soldering and Crimping in Car Repair

Soldering in car repair involves melting a filler metal to join electrical wires, creating a strong, conductive bond ideal for permanent connections in automotive wiring harnesses. Crimping, on the other hand, mechanically compresses a connector onto a wire without heat, ensuring quick, reliable, and vibration-resistant electrical connections used in sensor and battery terminals. Both techniques are essential for maintaining electrical integrity and durability in vehicle repair and maintenance.

What is Soldering? Pros and Cons

Soldering is a repair technique that joins metal components by melting a filler metal, typically solder, to create a strong electrical and mechanical bond. Its advantages include providing a reliable, conductive connection and the ability to join complex or delicate parts with precision. However, soldering requires proper heat control to avoid damage, is generally slower than crimping, and may be less suitable for high-vibration environments due to potential joint fatigue.

What is Crimping? Pros and Cons

Crimping is a technique used in electrical and mechanical repairs where a connector is joined to a cable by deforming one or both to create a secure connection without solder. Pros of crimping include faster installation, reliable mechanical strength, and reduced heat damage risk to components, making it ideal for high-volume or vibration-prone applications. Cons involve potential for improper crimps leading to poor conductivity and the necessity for specialized tools to ensure optimal connection quality.

Key Differences: Soldering vs Crimping

Soldering creates a strong electrical connection by melting metal alloy around wires, ensuring conductivity and mechanical strength, while crimping uses deforming metal connectors to secure wires without heat. Soldering requires precise temperature control and is ideal for permanent, high-reliability joints, whereas crimping offers quicker assembly with consistent results and easier maintenance. The choice depends on the application's demand for durability, environmental conditions, and required mechanical robustness.

Electrical Conductivity Comparison

Soldering provides superior electrical conductivity by creating a strong metallurgical bond that minimizes resistance at the connection point. Crimping relies on mechanical pressure to join wires, which can result in variable conductivity depending on crimp quality and materials used. High-quality soldered joints typically deliver more consistent conductivity, important for sensitive electronic applications.

Durability and Long-Term Reliability

Soldering provides superior long-term reliability by creating a solid metallic bond that resists oxidation and maintains electrical continuity over time. Crimping, while faster and less skill-intensive, may be more susceptible to loosening or corrosion under vibration and environmental stress. For critical repairs demanding maximum durability, soldered connections often outperform crimps in maintaining stable, low-resistance contacts.

Installation Process: Tools and Techniques

Soldering requires a soldering iron, flux, and solder wire to create a secure electrical connection by melting and fusing metals together. Crimping uses a specialized crimping tool to deform a metal sleeve around a wire, ensuring mechanical and electrical bonding without heat. The installation process for soldering demands careful temperature control and clean surfaces, whereas crimping emphasizes precise pressure and compatible connectors for reliability.

Safety Considerations for Both Methods

Soldering requires careful ventilation and protection from burns due to the high heat and toxic fumes produced by molten solder and flux. Crimping poses fewer inhalation risks but demands proper tool use to avoid pinched fingers and ensure secure, reliable connections that prevent electrical hazards. Both methods necessitate safety gloves and eye protection to minimize injury during repair processes.

Best Use Cases: When to Solder or Crimp

Soldering excels in creating permanent, conductive, and moisture-resistant electrical connections, ideal for delicate electronics and circuit board repairs. Crimping provides a faster, reliable mechanical bond suited for automotive wiring, heavy-gauge cables, and situations requiring vibration resistance. Choosing between soldering and crimping depends on the application's durability needs, electrical performance, and environmental exposure.

Expert Recommendations for Automotive Repairs

Experts recommend soldering for automotive wiring repairs due to its superior electrical conductivity and long-term durability under engine vibration. Crimping is favored for quick, reliable connections with minimal heat exposure, reducing wire insulation damage. High-quality connectors and proper tools are essential for both methods to ensure safety and performance in automotive electrical systems.

Soldering vs Crimping Infographic

cardiffo.com

cardiffo.com