Traditional alignment relies on mechanical tools and manual adjustments that can be time-consuming and less precise, often leading to uneven tire wear and compromised vehicle handling. Laser alignment employs advanced laser technology to deliver highly accurate measurements and adjustments, ensuring optimal wheel alignment for improved safety and fuel efficiency. Choosing laser alignment enhances repair quality by minimizing human error and providing quicker, more consistent results.

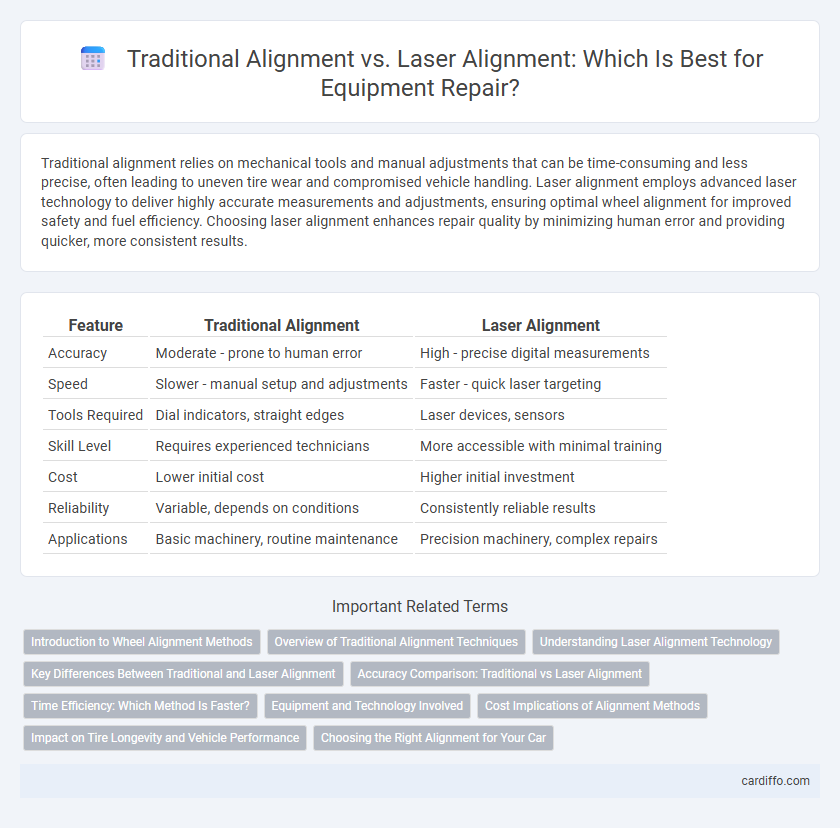

Table of Comparison

| Feature | Traditional Alignment | Laser Alignment |

|---|---|---|

| Accuracy | Moderate - prone to human error | High - precise digital measurements |

| Speed | Slower - manual setup and adjustments | Faster - quick laser targeting |

| Tools Required | Dial indicators, straight edges | Laser devices, sensors |

| Skill Level | Requires experienced technicians | More accessible with minimal training |

| Cost | Lower initial cost | Higher initial investment |

| Reliability | Variable, depends on conditions | Consistently reliable results |

| Applications | Basic machinery, routine maintenance | Precision machinery, complex repairs |

Introduction to Wheel Alignment Methods

Traditional wheel alignment uses mechanical tools such as camber gauges and turntables to adjust tire angles, providing basic correction based on manufacturer specifications. Laser alignment employs advanced laser technology and sensors to deliver precise measurements and more accurate adjustments, minimizing human error and improving vehicle handling. Understanding these methods helps determine the best approach for optimal tire wear and driving safety.

Overview of Traditional Alignment Techniques

Traditional alignment techniques primarily involve mechanical methods such as the use of dial indicators, straight edges, and feeler gauges to measure and adjust the position of components. These methods rely heavily on manual skill and experience to achieve precise alignment, often requiring multiple iterations and calibration checks. Despite being time-consuming, traditional alignment remains widely used due to its low initial cost and compatibility with various machinery types.

Understanding Laser Alignment Technology

Laser alignment technology uses precise light beams to measure wheel alignment angles, providing accuracy within fractions of a degree compared to traditional methods relying on mechanical gauges and visual estimates. This innovative system reduces human error, enhances diagnostic speed, and ensures optimal vehicle handling and tire longevity. The integration of advanced sensors and computerized analysis in laser alignment represents a significant advancement in automotive repair precision.

Key Differences Between Traditional and Laser Alignment

Traditional alignment relies on mechanical tools such as dial indicators and visual measurements, offering limited precision and often requiring manual adjustments. Laser alignment employs advanced laser beams and sensors, providing higher accuracy, faster setup times, and real-time digital readouts. The key differences lie in measurement accuracy, ease of use, and the ability to detect misalignments with minimal human error.

Accuracy Comparison: Traditional vs Laser Alignment

Traditional alignment relies on mechanical tools like dial indicators and measuring tapes, which can introduce human error and slight inaccuracies due to manual adjustments. Laser alignment uses high-precision laser technology that provides exact measurements and real-time feedback, significantly increasing alignment accuracy to within microns. This enhanced precision reduces equipment wear and improves overall operational efficiency compared to traditional methods.

Time Efficiency: Which Method Is Faster?

Traditional alignment typically requires more time due to manual adjustments and multiple measurement checks, often extending repair durations. Laser alignment uses precise, automated laser measurements that significantly reduce setup and correction times, enhancing workshop productivity. Faster alignment processes minimize vehicle downtime and allow technicians to service more cars efficiently.

Equipment and Technology Involved

Traditional alignment relies on mechanical tools such as turnplates, camber gauges, and bubble levels, which require manual adjustments and skilled technicians for precise measurements. Laser alignment utilizes advanced laser sensors, computerized cameras, and digital displays to deliver highly accurate and automated alignment readings with minimal human error. The integration of sophisticated software in laser systems enhances data analysis and alignment precision, significantly improving repair efficiency compared to traditional methods.

Cost Implications of Alignment Methods

Traditional alignment methods generally involve lower upfront costs but may require more frequent adjustments, leading to higher long-term maintenance expenses. Laser alignment offers higher precision, reducing wear and tear on vehicle components and potentially lowering overall repair and replacement costs. Investing in laser alignment can yield cost savings by improving accuracy and extending the lifespan of tires and suspension systems.

Impact on Tire Longevity and Vehicle Performance

Traditional alignment methods rely on manual adjustments that can lead to less precise measurements, potentially causing uneven tire wear and reduced tire longevity. Laser alignment uses advanced laser technology to provide highly accurate alignment angles, improving tire wear patterns and ensuring optimal vehicle handling and performance. Vehicles aligned with laser systems experience enhanced fuel efficiency, smoother steering response, and extended tire life compared to traditional alignment techniques.

Choosing the Right Alignment for Your Car

Traditional alignment relies on mechanical tools and manual adjustments, making it a cost-effective choice for routine wheel alignment needs. Laser alignment uses advanced technology to provide precise measurements, improving accuracy and extending tire life, ideal for modern vehicles with complex suspension systems. Selecting the right alignment depends on your car's make, model, and driving conditions, ensuring optimal performance and safety.

Traditional alignment vs laser alignment Infographic

cardiffo.com

cardiffo.com