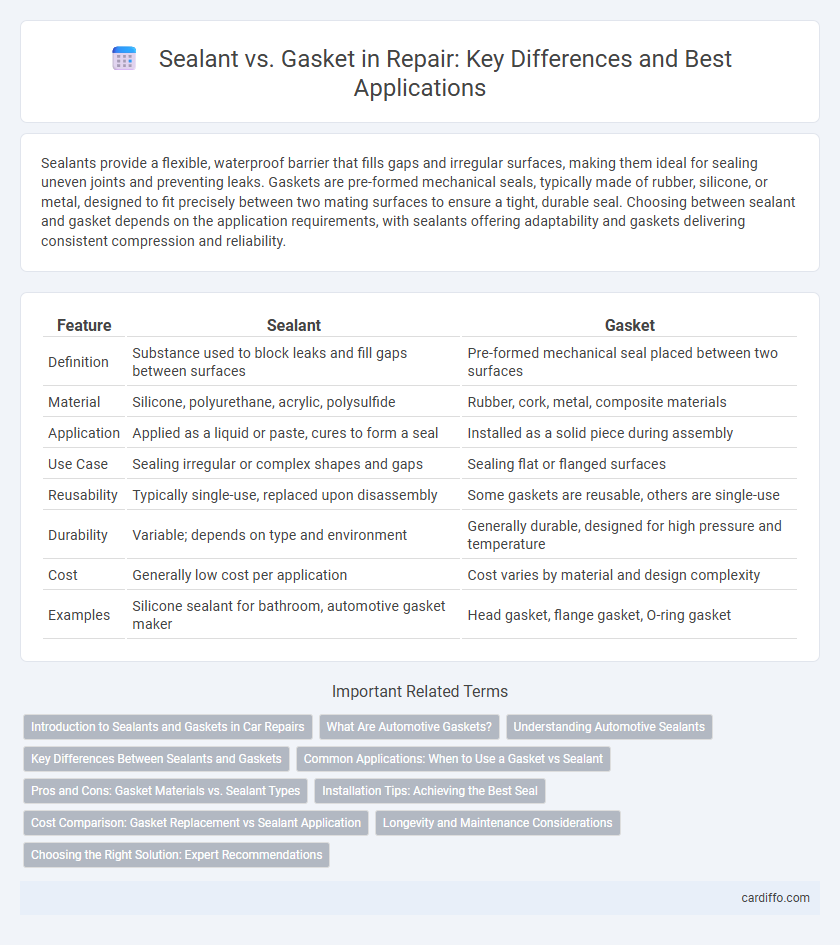

Sealants provide a flexible, waterproof barrier that fills gaps and irregular surfaces, making them ideal for sealing uneven joints and preventing leaks. Gaskets are pre-formed mechanical seals, typically made of rubber, silicone, or metal, designed to fit precisely between two mating surfaces to ensure a tight, durable seal. Choosing between sealant and gasket depends on the application requirements, with sealants offering adaptability and gaskets delivering consistent compression and reliability.

Table of Comparison

| Feature | Sealant | Gasket |

|---|---|---|

| Definition | Substance used to block leaks and fill gaps between surfaces | Pre-formed mechanical seal placed between two surfaces |

| Material | Silicone, polyurethane, acrylic, polysulfide | Rubber, cork, metal, composite materials |

| Application | Applied as a liquid or paste, cures to form a seal | Installed as a solid piece during assembly |

| Use Case | Sealing irregular or complex shapes and gaps | Sealing flat or flanged surfaces |

| Reusability | Typically single-use, replaced upon disassembly | Some gaskets are reusable, others are single-use |

| Durability | Variable; depends on type and environment | Generally durable, designed for high pressure and temperature |

| Cost | Generally low cost per application | Cost varies by material and design complexity |

| Examples | Silicone sealant for bathroom, automotive gasket maker | Head gasket, flange gasket, O-ring gasket |

Introduction to Sealants and Gaskets in Car Repairs

Sealants and gaskets play crucial roles in car repairs by preventing fluid leaks and ensuring airtight connections between engine components. Sealants are flexible materials applied as liquids or pastes that harden to fill gaps, ideal for irregular surfaces or minor imperfections. Gaskets are pre-formed components made from rubber, cork, or metal, providing consistent compression and sealing between flat surfaces such as cylinder heads and intake manifolds.

What Are Automotive Gaskets?

Automotive gaskets are precision-engineered components designed to create a secure, leak-proof seal between two mating surfaces within an engine or other vehicle systems. They prevent fluid leaks, maintain pressure, and ensure optimal engine performance by compensating for surface irregularities and thermal expansion. Common materials for gaskets include rubber, cork, metal, and composite substances, each selected based on specific temperature and pressure requirements in automotive applications.

Understanding Automotive Sealants

Automotive sealants provide flexible bonding and sealing capabilities crucial for preventing fluid leaks in engine components where gaskets alone may fail. Sealants adapt to irregular surfaces and thermal expansion, creating a durable barrier that enhances the longevity of repairs. Choosing the right automotive sealant, such as silicone or anaerobic types, ensures optimal compatibility with materials and operating temperatures.

Key Differences Between Sealants and Gaskets

Sealants are flexible substances applied to surfaces to fill gaps and prevent fluid leakage, adapting to irregular shapes and curing in place, whereas gaskets are pre-formed mechanical seals made from materials like rubber, silicone, or metal designed to fit between two mating surfaces. Sealants offer versatility in application, conforming to complex joints and providing waterproofing, while gaskets provide consistent compression resistance and are ideal for repetitive assembly and disassembly. Key differences include application method, material form, and suitability for dynamic versus static sealing environments.

Common Applications: When to Use a Gasket vs Sealant

Gaskets are commonly used in mechanical assemblies where precise, repeatable sealing is required between rigid surfaces like flanges and engine components. Sealants are ideal for irregular or uneven surfaces, filling gaps and providing a flexible barrier in plumbing joints, automotive repairs, and HVAC systems. Understanding the specific application environment and material compatibility ensures effective sealing performance and prevents leaks.

Pros and Cons: Gasket Materials vs. Sealant Types

Gasket materials such as rubber, silicone, and cork offer reliable mechanical sealing with consistent thickness and ease of replacement, but may deteriorate under extreme temperatures and chemical exposure. Sealant types like silicone, polyurethane, and anaerobic sealants provide versatile application and excellent chemical resistance, though they require precise curing time and can be messy to apply. Selecting between gaskets and sealants depends on factors like operating pressure, temperature range, ease of maintenance, and environmental conditions.

Installation Tips: Achieving the Best Seal

Proper surface preparation is critical when installing sealants or gaskets to achieve the best seal, ensuring cleanliness and dryness to promote adhesion. Applying sealants evenly with the correct bead size prevents gaps and reduces the risk of leakage in high-pressure systems. For gaskets, using the recommended torque specifications during tightening avoids deformation and ensures a uniform sealing surface that maintains integrity over time.

Cost Comparison: Gasket Replacement vs Sealant Application

Gasket replacement generally incurs higher costs due to the price of new gasket materials and the labor-intensive removal and installation process, especially for complex assemblies. Sealant application often offers a more budget-friendly alternative, requiring less labor and lower material expenses while providing effective sealing in many scenarios. However, the long-term cost efficiency of sealants depends on the application's pressure and temperature conditions, which may necessitate more frequent maintenance compared to durable gaskets.

Longevity and Maintenance Considerations

Sealants provide flexibility and can conform to irregular surfaces, offering longer-lasting protection against leaks but may require periodic reapplication due to degradation from environmental exposure. Gaskets, made from durable materials like rubber or silicone, offer consistent compression and typically require less frequent replacement, though they can fail if improperly installed or exposed to extreme temperatures. Maintenance strategies should consider the specific operating conditions and ease of access, with sealants favored for complex shapes and gaskets preferred for standardized flanges.

Choosing the Right Solution: Expert Recommendations

Selecting the right sealing method depends on factors such as pressure tolerance, temperature range, and the specific application environment. Sealants offer flexibility for irregular surfaces and minor imperfections, making them ideal for dynamic or complex joints. Gaskets provide reliable, consistent sealing in high-pressure systems, where precise dimensional control and material compatibility ensure long-term durability and leak prevention.

Sealant vs gasket Infographic

cardiffo.com

cardiffo.com