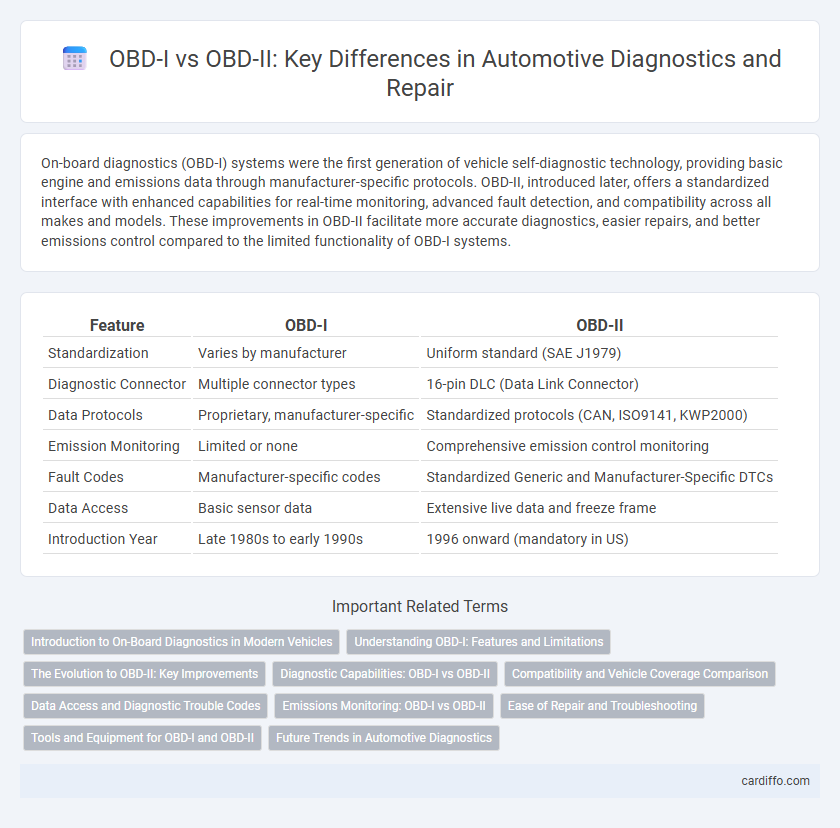

On-board diagnostics (OBD-I) systems were the first generation of vehicle self-diagnostic technology, providing basic engine and emissions data through manufacturer-specific protocols. OBD-II, introduced later, offers a standardized interface with enhanced capabilities for real-time monitoring, advanced fault detection, and compatibility across all makes and models. These improvements in OBD-II facilitate more accurate diagnostics, easier repairs, and better emissions control compared to the limited functionality of OBD-I systems.

Table of Comparison

| Feature | OBD-I | OBD-II |

|---|---|---|

| Standardization | Varies by manufacturer | Uniform standard (SAE J1979) |

| Diagnostic Connector | Multiple connector types | 16-pin DLC (Data Link Connector) |

| Data Protocols | Proprietary, manufacturer-specific | Standardized protocols (CAN, ISO9141, KWP2000) |

| Emission Monitoring | Limited or none | Comprehensive emission control monitoring |

| Fault Codes | Manufacturer-specific codes | Standardized Generic and Manufacturer-Specific DTCs |

| Data Access | Basic sensor data | Extensive live data and freeze frame |

| Introduction Year | Late 1980s to early 1990s | 1996 onward (mandatory in US) |

Introduction to On-Board Diagnostics in Modern Vehicles

On-board diagnostics (OBD) systems provide critical data for vehicle repair and maintenance by monitoring engine performance and emission controls. OBD-I, introduced in the early 1980s, offered limited diagnostic capabilities with manufacturer-specific codes, whereas OBD-II, standardized in 1996, delivers real-time data and universal codes through enhanced sensors and communication protocols. Modern vehicles rely on OBD-II for comprehensive fault detection, enabling technicians to efficiently diagnose issues and ensure compliance with emission standards.

Understanding OBD-I: Features and Limitations

OBD-I systems, introduced in the early 1980s, provide basic diagnostic information through manufacturer-specific protocols and limited sensor data. These early systems monitor essential engine components but lack standardized codes, making it difficult to interpret and compare fault information across different vehicle makes. The limited real-time data and inconsistent fault code formats in OBD-I restrict effective troubleshooting compared to the more advanced, unified diagnostics offered by OBD-II systems.

The Evolution to OBD-II: Key Improvements

The evolution from OBD-I to OBD-II greatly enhanced vehicle diagnostics by standardizing data protocols and expanding the range of monitored systems, allowing for more precise fault detection and emission controls. OBD-II introduced a unified 16-pin connector and standardized trouble codes, facilitating easier access to real-time data across different vehicle makes and models. This advancement significantly improved repair efficiency, emissions compliance, and overall vehicle maintenance capabilities.

Diagnostic Capabilities: OBD-I vs OBD-II

OBD-I systems provide basic diagnostic capabilities primarily focused on emissions control and simple fault detection, with limited standardized codes and real-time data access. In contrast, OBD-II offers enhanced diagnostic functionality, featuring comprehensive standardized trouble codes, advanced sensor monitoring, and live data streams for more accurate fault identification and troubleshooting. The expanded diagnostic scope of OBD-II supports improved repair precision and vehicle maintenance efficiency.

Compatibility and Vehicle Coverage Comparison

OBD-I systems, introduced in the early 1980s, offer limited compatibility primarily with vehicles manufactured before 1996, featuring manufacturer-specific protocols and connectors. In contrast, OBD-II, standardized in 1996, provides universal compatibility across all gasoline-powered vehicles in the U.S. and newer models globally, supporting standardized diagnostic trouble codes and a uniform 16-pin connector. This expansive vehicle coverage and interoperability make OBD-II essential for comprehensive diagnostics and emissions testing compared to the fragmented OBD-I systems.

Data Access and Diagnostic Trouble Codes

OBD-I systems provide limited data access with manufacturer-specific diagnostic trouble codes, often requiring proprietary tools to retrieve information. OBD-II offers standardized diagnostic trouble codes (DTCs) and broad data accessibility, enabling universal scan tools to read real-time data and clear faults across different vehicle makes. The enhanced data stream in OBD-II supports more precise troubleshooting and improves vehicle repair efficiency.

Emissions Monitoring: OBD-I vs OBD-II

OBD-II provides more comprehensive emissions monitoring than OBD-I by continuously tracking a wider range of emission control components, including the catalytic converter, oxygen sensors, and evaporative emissions system. Unlike OBD-I, which offers limited diagnostic capabilities and inconsistent data formats, OBD-II standardizes fault codes and enables real-time data access to detect emissions-related malfunctions promptly. This enhanced monitoring helps ensure vehicles meet stricter environmental regulations and reduces harmful pollutants more effectively.

Ease of Repair and Troubleshooting

OBD-II systems offer improved ease of repair and troubleshooting compared to OBD-I by providing standardized diagnostic trouble codes (DTCs) that allow mechanics to quickly identify and address vehicle issues. The enhanced communication protocols and real-time data access in OBD-II reduce diagnostic time and increase repair accuracy. In contrast, OBD-I systems use manufacturer-specific codes and lack comprehensive data streams, making fault detection more complex and time-consuming.

Tools and Equipment for OBD-I and OBD-II

OBD-I tools primarily consist of basic code readers and manual jumper wires for data retrieval, designed for limited diagnostic protocols in pre-1996 vehicles. OBD-II diagnostic equipment features advanced scan tools with standardized connectors, supporting extensive real-time data, freeze frame captures, and enhanced emissions monitoring for post-1996 vehicles. Technicians rely on sophisticated OBD-II software and hardware interfaces to access comprehensive diagnostic trouble codes (DTCs) and perform in-depth system tests unavailable with OBD-I tools.

Future Trends in Automotive Diagnostics

On-board diagnostics (OBD-II) systems have significantly advanced from OBD-I by providing standardized access to real-time vehicle data and comprehensive fault codes, enabling more precise diagnostics and repair. Future trends in automotive diagnostics focus on integrating telematics, artificial intelligence, and cloud connectivity to allow remote monitoring, predictive maintenance, and enhanced vehicle health insights. These innovations aim to improve repair efficiency, reduce downtime, and support the growing complexity of electric and autonomous vehicles.

On-board diagnostics (OBD-I) vs OBD-II Infographic

cardiffo.com

cardiffo.com