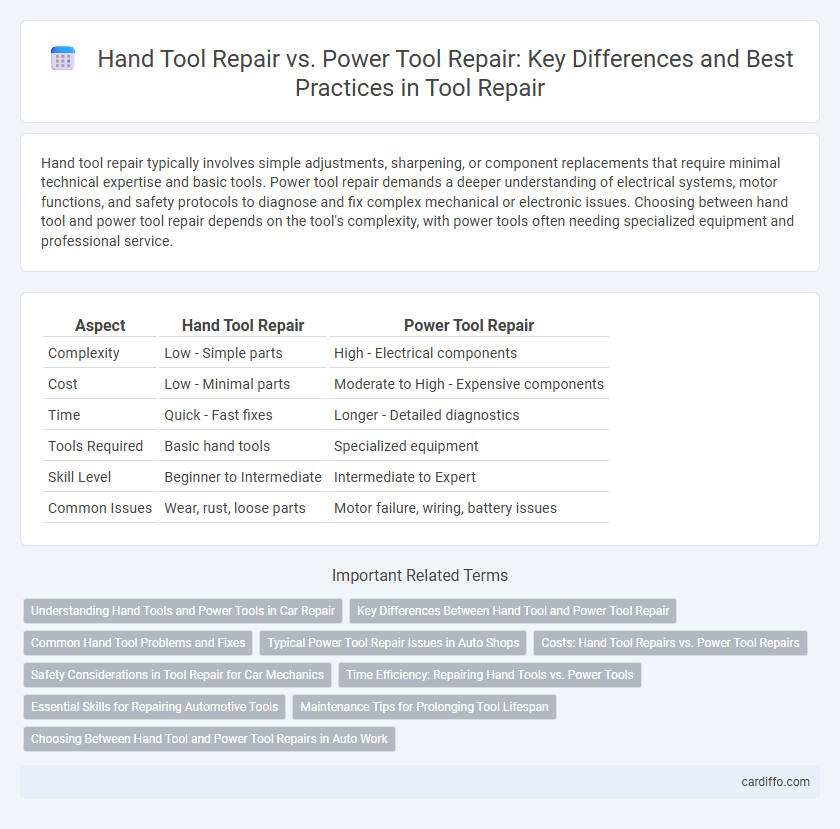

Hand tool repair typically involves simple adjustments, sharpening, or component replacements that require minimal technical expertise and basic tools. Power tool repair demands a deeper understanding of electrical systems, motor functions, and safety protocols to diagnose and fix complex mechanical or electronic issues. Choosing between hand tool and power tool repair depends on the tool's complexity, with power tools often needing specialized equipment and professional service.

Table of Comparison

| Aspect | Hand Tool Repair | Power Tool Repair |

|---|---|---|

| Complexity | Low - Simple parts | High - Electrical components |

| Cost | Low - Minimal parts | Moderate to High - Expensive components |

| Time | Quick - Fast fixes | Longer - Detailed diagnostics |

| Tools Required | Basic hand tools | Specialized equipment |

| Skill Level | Beginner to Intermediate | Intermediate to Expert |

| Common Issues | Wear, rust, loose parts | Motor failure, wiring, battery issues |

Understanding Hand Tools and Power Tools in Car Repair

Hand tools in car repair, such as wrenches and screwdrivers, provide precision and control for tasks requiring detailed manual adjustments, enabling mechanics to work efficiently in tight spaces. Power tools, including impact wrenches and electric drills, deliver high torque and speed, significantly reducing the time needed for repetitive or heavy-duty operations like loosening bolts or drilling. Mastery of both hand tools and power tools enhances overall repair effectiveness, balancing finesse with power for optimal automotive maintenance.

Key Differences Between Hand Tool and Power Tool Repair

Hand tool repair primarily involves manual techniques such as sharpening, tightening, and replacing small parts, requiring minimal equipment. Power tool repair demands specialized knowledge of electrical components, motor diagnostics, and safety protocols to address complex issues like motor failures or circuit malfunctions. Time efficiency and precision are greater in power tool repair due to technology dependence, whereas hand tool repair is typically more straightforward and cost-effective.

Common Hand Tool Problems and Fixes

Common hand tool problems include rusted metal parts, loose or cracked handles, and dull cutting edges. Fixes often involve cleaning and lubricating metal components, tightening or replacing handles, and sharpening blades using whetstones or grinders. Regular maintenance extends tool life and ensures efficient performance during repairs.

Typical Power Tool Repair Issues in Auto Shops

Typical power tool repair issues in auto shops include motor burnout, worn brushes, and faulty switches, which commonly arise from heavy usage and exposure to dust and grease. Gear damage and battery malfunctions are also frequent problems in cordless tools due to mechanical stress and poor charging practices. Addressing these repairs promptly ensures optimal tool performance and minimizes downtime in automotive maintenance operations.

Costs: Hand Tool Repairs vs. Power Tool Repairs

Hand tool repairs generally incur lower costs due to simpler mechanisms and fewer replacement parts, making maintenance affordable and quick. Power tool repairs often involve higher expenses driven by complex electronics, motor replacements, and specialized labor. Comparing repair costs highlights that hand tools provide cost-effective longevity, while power tools may require significant investment to restore optimal functionality.

Safety Considerations in Tool Repair for Car Mechanics

Hand tool repair for car mechanics often involves simpler safety measures such as wearing gloves and ensuring tools are properly cleaned and inspected for damage to prevent injury. Power tool repair requires stricter protocols, including disconnecting power sources, using lockout-tagout procedures, and inspecting electrical components to avoid shocks and accidental startups. Emphasizing proper training and personal protective equipment (PPE) minimizes risks associated with both hand and power tool repairs in automotive maintenance.

Time Efficiency: Repairing Hand Tools vs. Power Tools

Repairing hand tools typically requires less time due to their simpler mechanical structures and fewer components. Power tool repair often involves complex diagnostics, electrical inspections, and specialized parts replacement, leading to longer service durations. Efficient scheduling and access to specific replacement parts can significantly impact the overall repair time for power tools compared to hand tools.

Essential Skills for Repairing Automotive Tools

Mastering hand tool repair requires precision in handling mechanical components such as wrenches, screwdrivers, and pliers, including techniques like cleaning, lubrication, and part replacement. Power tool repair demands expertise in electrical systems, motor diagnostics, and circuit board troubleshooting, essential for tools like electric drills and impact wrenches. Both repair types necessitate a strong knowledge of safety protocols, technical schematics, and appropriate use of diagnostic equipment to maintain optimal automotive tool performance.

Maintenance Tips for Prolonging Tool Lifespan

Regular lubrication and cleaning are essential for both hand tool repair and power tool repair to prevent rust and ensure smooth operation. Inspecting and tightening screws, bolts, and moving parts can significantly extend the lifespan of hand tools, while power tools benefit from periodic motor checks and battery maintenance. Storing tools in a dry, organized space reduces wear and minimizes the risk of damage, supporting long-term tool performance.

Choosing Between Hand Tool and Power Tool Repairs in Auto Work

Hand tool repair in auto work ensures precision and control, making it ideal for delicate tasks like fine adjustments and detailed component work. Power tool repair offers efficiency and speed for heavy-duty jobs such as loosening rusted bolts or large-scale disassembly. Assessing the scope of damage and the specific auto repair requirements determines whether hand tool or power tool maintenance is more suitable for optimal performance and longevity.

hand tool repair vs power tool repair Infographic

cardiffo.com

cardiffo.com