Plastic welding creates a strong, seamless bond by melting and fusing the plastic pieces together, resulting in a durable and long-lasting repair. Epoxy repair involves applying an adhesive that chemically bonds to surfaces, which can be effective but may not offer the same structural integrity as plastic welding. For repairs requiring high strength and resistance to stress, plastic welding is often the preferred method over epoxy.

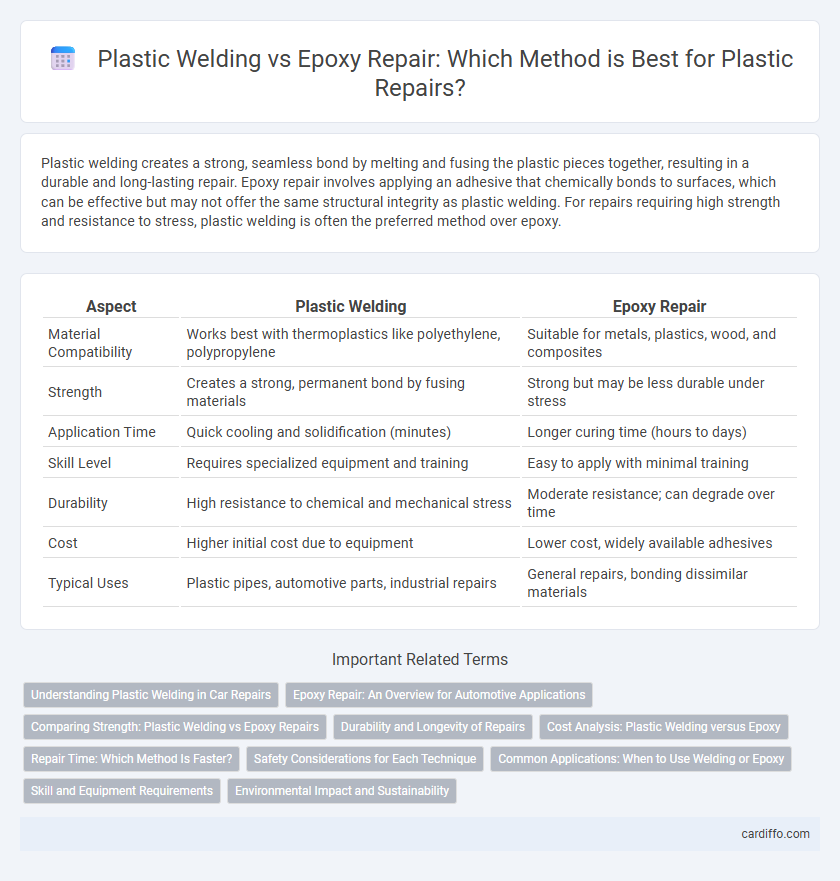

Table of Comparison

| Aspect | Plastic Welding | Epoxy Repair |

|---|---|---|

| Material Compatibility | Works best with thermoplastics like polyethylene, polypropylene | Suitable for metals, plastics, wood, and composites |

| Strength | Creates a strong, permanent bond by fusing materials | Strong but may be less durable under stress |

| Application Time | Quick cooling and solidification (minutes) | Longer curing time (hours to days) |

| Skill Level | Requires specialized equipment and training | Easy to apply with minimal training |

| Durability | High resistance to chemical and mechanical stress | Moderate resistance; can degrade over time |

| Cost | Higher initial cost due to equipment | Lower cost, widely available adhesives |

| Typical Uses | Plastic pipes, automotive parts, industrial repairs | General repairs, bonding dissimilar materials |

Understanding Plastic Welding in Car Repairs

Plastic welding in car repairs involves using heat to fuse plastic components, creating a strong, seamless bond that restores structural integrity. Unlike epoxy repair, which relies on adhesives and may degrade over time, plastic welding offers durability and resistance to environmental factors such as heat, moisture, and chemicals. Repair shops specializing in automotive plastics often prefer plastic welding for bumpers, dashboards, and other plastic parts to ensure long-lasting repairs and maintain vehicle safety standards.

Epoxy Repair: An Overview for Automotive Applications

Epoxy repair in automotive applications offers a durable, chemical-resistant bonding solution suitable for plastic, metal, and composite materials commonly found in vehicle components. Its strong adhesive properties and gap-filling capabilities enable effective restoration of cracked or broken parts without the need for specialized equipment. Epoxy resins provide high mechanical strength and resistance to environmental factors such as moisture, heat, and vibration, making them ideal for both exterior and interior automotive repairs.

Comparing Strength: Plastic Welding vs Epoxy Repairs

Plastic welding creates a stronger, more durable bond by fusing the plastic at the molecular level, often matching or exceeding the original material's strength. Epoxy repairs rely on adhesive strength, which can be effective but generally remain weaker and less resilient under stress or heat compared to plastic welding. For load-bearing or high-stress applications, plastic welding is typically the superior choice due to its enhanced structural integrity.

Durability and Longevity of Repairs

Plastic welding offers superior durability and longevity compared to epoxy repair, as it fuses materials at a molecular level, creating a strong, seamless bond that can withstand stress and environmental factors. Epoxy repair, while easier to apply, tends to degrade over time when exposed to UV light, moisture, and heat, resulting in weaker joints and potential failure. For long-lasting repairs in high-stress or outdoor conditions, plastic welding is generally the preferred method due to its resilience and structural integrity.

Cost Analysis: Plastic Welding versus Epoxy

Plastic welding offers a more durable and long-term solution for repairing plastic materials, often resulting in higher initial labor costs but lower maintenance expenses over time. Epoxy repair presents a cost-effective option with lower upfront materials and application costs, ideal for smaller or less critical repairs yet may require frequent touch-ups. Evaluating total ownership cost, including durability and repair frequency, reveals plastic welding as more economical for extensive or load-bearing repairs, while epoxy suits quick fixes and budget constraints.

Repair Time: Which Method Is Faster?

Plastic welding typically offers faster repair times compared to epoxy repair because it involves melting and fusing the plastic directly, allowing for immediate solidification and use. Epoxy repairs require longer curing periods, often ranging from several minutes to hours, depending on the product and environmental conditions. For urgent fixes where downtime must be minimized, plastic welding provides a more efficient solution.

Safety Considerations for Each Technique

Plastic welding offers a safer repair method for thermoplastics as it eliminates the need for toxic adhesives, reducing exposure to harmful fumes and chemicals often associated with epoxy repair. Epoxy repair requires proper ventilation and protective equipment due to the potential release of volatile organic compounds (VOCs) and skin irritation risks. Careful adherence to manufacturer safety guidelines is essential in both techniques to prevent accidents and ensure a health-conscious repair environment.

Common Applications: When to Use Welding or Epoxy

Plastic welding is ideal for repairing structural components in automotive bumpers, fuel tanks, and pipes due to its strong, permanent bond that withstands pressure and heat. Epoxy repair suits non-structural fixes like small cracks or surface damage on household items, electronics, and decorative plastics where flexibility and ease of application are prioritized. Choosing between welding and epoxy depends on the repair's mechanical demands, environmental exposure, and the type of plastic material involved.

Skill and Equipment Requirements

Plastic welding demands specialized equipment such as heat guns or ultrasonic welders and requires skilled operators trained in controlling temperature and pressure for effective bonding. Epoxy repair involves using two-part adhesive compounds that need less technical expertise but still requires precision in mixing and application to ensure strong adhesion. While plastic welding achieves durable, seamless joints ideal for structural repairs, epoxy offers a more accessible solution for quick fixes on varied plastic surfaces.

Environmental Impact and Sustainability

Plastic welding offers a more sustainable repair method by creating a strong, permanent bond through heat fusion, reducing the need for disposable adhesives and minimizing chemical waste. Epoxy repair involves curing chemical compounds that can release volatile organic compounds (VOCs), contributing to environmental pollution and creating non-recyclable residue. Choosing plastic welding over epoxy repair supports eco-friendly practices by promoting material recyclability and lowering the carbon footprint associated with plastic product maintenance.

Plastic welding vs epoxy repair Infographic

cardiffo.com

cardiffo.com