Rebuilding an alternator involves refurbishing the existing components, which can be cost-effective and environmentally friendly, while replacing an alternator provides a brand-new unit offering guaranteed reliability and longer lifespan. Rebuilding may be suitable for minor damages or worn-out parts, but replacement ensures complete restoration and reduces the risk of future failures. Choosing between rebuilding and replacing depends on factors like budget, vehicle age, and the extent of alternator damage.

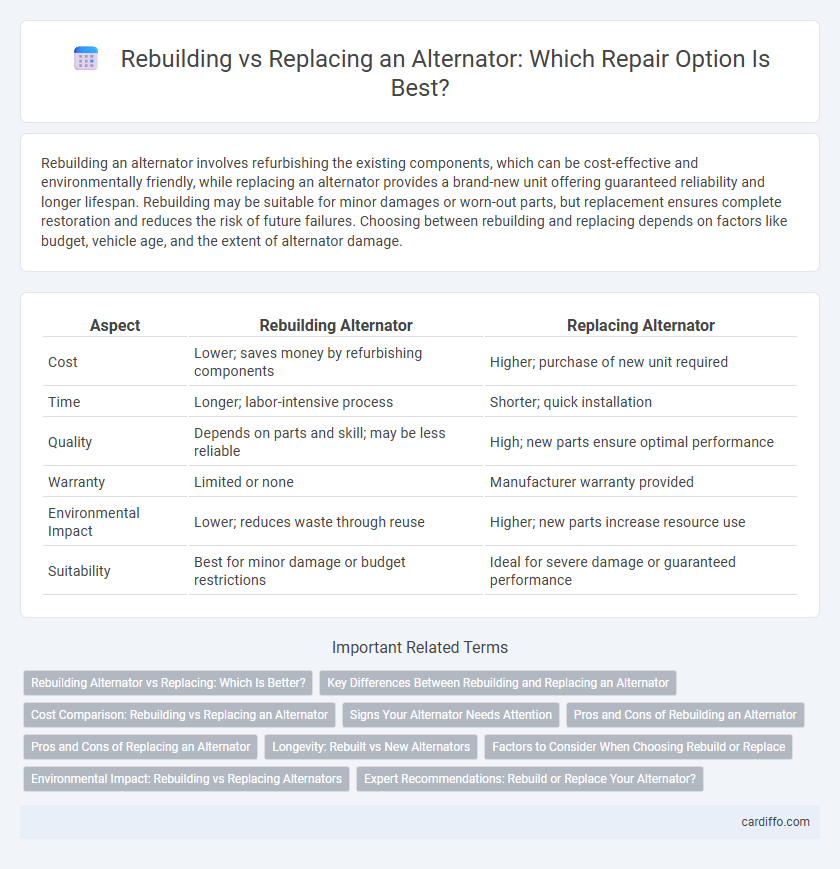

Table of Comparison

| Aspect | Rebuilding Alternator | Replacing Alternator |

|---|---|---|

| Cost | Lower; saves money by refurbishing components | Higher; purchase of new unit required |

| Time | Longer; labor-intensive process | Shorter; quick installation |

| Quality | Depends on parts and skill; may be less reliable | High; new parts ensure optimal performance |

| Warranty | Limited or none | Manufacturer warranty provided |

| Environmental Impact | Lower; reduces waste through reuse | Higher; new parts increase resource use |

| Suitability | Best for minor damage or budget restrictions | Ideal for severe damage or guaranteed performance |

Rebuilding Alternator vs Replacing: Which Is Better?

Rebuilding an alternator involves refurbishing its components like brushes, bearings, and diodes, often costing less than a full replacement and reducing waste. Replacing an alternator guarantees a brand-new unit with a full warranty and longer lifespan but comes at a higher price. The decision hinges on factors such as cost, vehicle age, availability of parts, and long-term reliability requirements.

Key Differences Between Rebuilding and Replacing an Alternator

Rebuilding an alternator involves disassembling, cleaning, and replacing worn components, which can be cost-effective and extend the life of the original unit but requires skilled labor and time. Replacing an alternator installs a completely new or remanufactured unit, ensuring reliability and often comes with a warranty but typically incurs higher upfront costs. Key differences include cost, turnaround time, warranty availability, and the potential lifespan of the repaired or replaced alternator.

Cost Comparison: Rebuilding vs Replacing an Alternator

Rebuilding an alternator typically costs between $100 and $300, significantly less than the $400 to $800 price range for a new alternator replacement. Rebuilt alternators can extend the lifespan of your vehicle's charging system while offering savings on parts and labor. However, the durability and warranty coverage of a new alternator often justify the higher initial expense for long-term reliability.

Signs Your Alternator Needs Attention

Signs your alternator needs attention include dimming headlights, warning lights on the dashboard, and unusual noises like grinding or whining. Rebuilding the alternator can be a cost-effective solution if components like the brushes or bearings show wear but the core structure remains intact. Replacing the alternator is often recommended when there is extensive damage or frequent failures that affect the vehicle's electrical performance and reliability.

Pros and Cons of Rebuilding an Alternator

Rebuilding an alternator offers cost savings compared to full replacement by allowing the reuse of core components while restoring functionality through new parts like brushes, bearings, and diodes. However, the rebuilt alternator may have a shorter lifespan and less reliability than a brand-new unit, especially if wear or damage is extensive. This option suits vehicles with rare or expensive alternators but requires precise labor and quality parts to ensure performance and longevity.

Pros and Cons of Replacing an Alternator

Replacing an alternator ensures restoring a vehicle's electrical system to optimal performance, offering a reliable solution with a brand-new component that minimizes the risk of future failures. New alternators often come with warranties, providing peace of mind and potentially lower long-term maintenance costs. However, the higher upfront cost and potential compatibility issues with older vehicle models can be significant drawbacks compared to rebuilding options.

Longevity: Rebuilt vs New Alternators

Rebuilt alternators offer a cost-effective solution with longevity dependent on the quality of parts and workmanship involved in the rebuild process. New alternators typically provide a longer lifespan due to factory-tested components and warranties that assure performance over time. Choosing between rebuilding and replacing an alternator often hinges on balancing immediate expenses against expected durability and reliability.

Factors to Consider When Choosing Rebuild or Replace

When deciding between rebuilding or replacing an alternator, key factors to consider include the alternator's age, the extent of internal damage, and cost-effectiveness. Rebuilding may be suitable for high-quality or rare alternators with minor wear, while replacement is often preferable for severely damaged or outdated units. Availability of parts, warranty coverage, and labor costs also influence the decision-making process.

Environmental Impact: Rebuilding vs Replacing Alternators

Rebuilding alternators significantly reduces environmental impact by minimizing electronic waste and conserving raw materials compared to full replacements. Rebuilding processes often involve refurbishing key components, leading to lower carbon emissions and less resource extraction than manufacturing new alternators. Selecting rebuilding over replacing supports sustainable automotive practices by extending the lifespan of existing parts and reducing landfill contributions.

Expert Recommendations: Rebuild or Replace Your Alternator?

Expert recommendations for alternator repair emphasize assessing the extent of wear and damage before deciding between rebuilding or replacing the unit. Rebuilding an alternator involves refurbishing internal components such as bearings, brushes, and diodes, which can be cost-effective for moderately worn units but may compromise long-term reliability. Replacing the alternator with a new or remanufactured unit ensures optimal performance and warranty coverage, especially for extensively damaged or high-mileage vehicles.

Rebuilding alternator vs replacing alternator Infographic

cardiffo.com

cardiffo.com