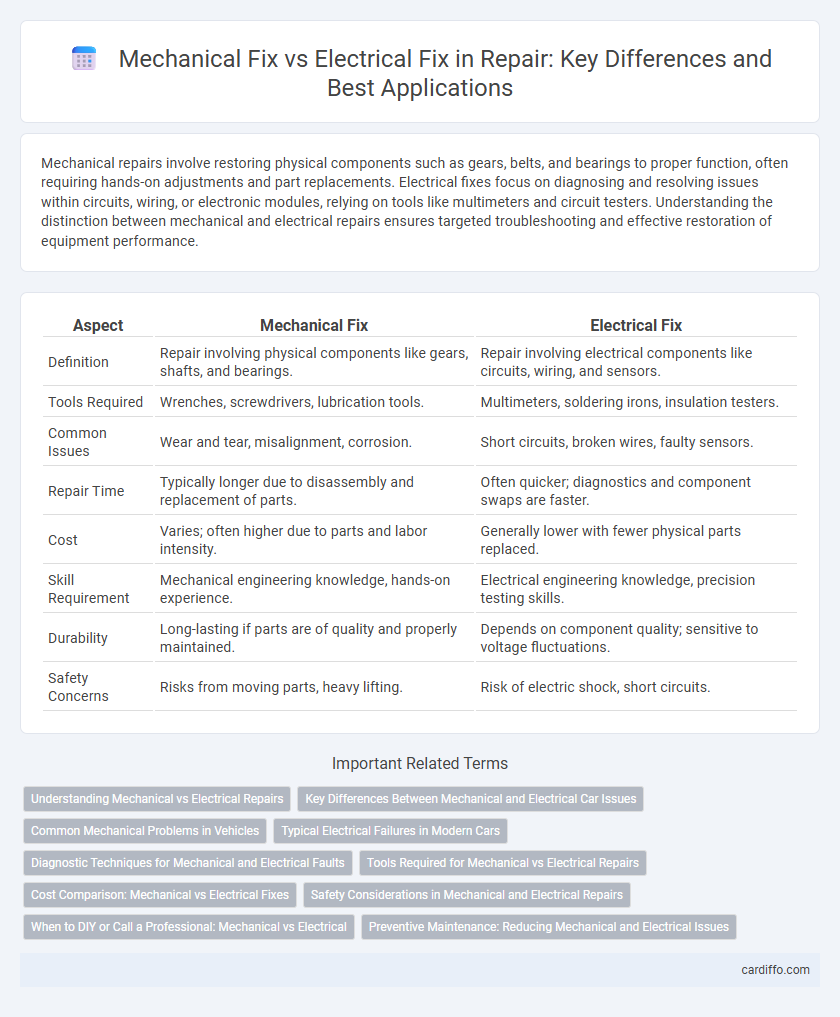

Mechanical repairs involve restoring physical components such as gears, belts, and bearings to proper function, often requiring hands-on adjustments and part replacements. Electrical fixes focus on diagnosing and resolving issues within circuits, wiring, or electronic modules, relying on tools like multimeters and circuit testers. Understanding the distinction between mechanical and electrical repairs ensures targeted troubleshooting and effective restoration of equipment performance.

Table of Comparison

| Aspect | Mechanical Fix | Electrical Fix |

|---|---|---|

| Definition | Repair involving physical components like gears, shafts, and bearings. | Repair involving electrical components like circuits, wiring, and sensors. |

| Tools Required | Wrenches, screwdrivers, lubrication tools. | Multimeters, soldering irons, insulation testers. |

| Common Issues | Wear and tear, misalignment, corrosion. | Short circuits, broken wires, faulty sensors. |

| Repair Time | Typically longer due to disassembly and replacement of parts. | Often quicker; diagnostics and component swaps are faster. |

| Cost | Varies; often higher due to parts and labor intensity. | Generally lower with fewer physical parts replaced. |

| Skill Requirement | Mechanical engineering knowledge, hands-on experience. | Electrical engineering knowledge, precision testing skills. |

| Durability | Long-lasting if parts are of quality and properly maintained. | Depends on component quality; sensitive to voltage fluctuations. |

| Safety Concerns | Risks from moving parts, heavy lifting. | Risk of electric shock, short circuits. |

Understanding Mechanical vs Electrical Repairs

Mechanical repairs involve addressing physical components such as gears, bearings, and belts that require manual adjustments or replacements to restore functionality. Electrical fixes focus on diagnosing and correcting issues within wiring, circuits, or electronic components using specialized tools and techniques. Mastery of both repair types demands distinct skill sets, with mechanical repairs emphasizing hands-on craftsmanship and electrical repairs requiring knowledge of electrical theory and safety protocols.

Key Differences Between Mechanical and Electrical Car Issues

Mechanical car issues primarily involve physical components such as the engine, transmission, and brakes, requiring hands-on repairs like replacing worn-out parts or fixing leaks. Electrical car issues focus on systems powered by the vehicle's battery and wiring, including sensors, wiring harnesses, and control modules, often necessitating diagnostic tools to identify faults. Understanding these key differences is essential for accurate diagnosis and efficient repair, as mechanical problems usually demand manual adjustment or part replacement, while electrical issues often hinge on circuit testing and software updates.

Common Mechanical Problems in Vehicles

Common mechanical problems in vehicles include issues such as worn-out brake pads, faulty suspension components, and engine overheating caused by coolant leaks or radiator failure. Mechanical repairs often involve replacing or adjusting physical parts like belts, gears, and bearings that directly affect a car's performance and safety. Unlike electrical fixes, mechanical repairs focus on restoring the vehicle's moving parts and structural integrity to ensure reliable functionality.

Typical Electrical Failures in Modern Cars

Typical electrical failures in modern cars often involve faulty sensors, malfunctioning alternators, and wiring issues that disrupt the vehicle's electronic control units (ECUs). Unlike mechanical repairs that address physical components like engines and transmissions, electrical fixes require diagnostic tools to identify short circuits, blown fuses, or failed modules. Efficient repair of electrical problems ensures the proper functioning of critical systems such as engine management, infotainment, and safety controls.

Diagnostic Techniques for Mechanical and Electrical Faults

Effective diagnostic techniques for mechanical faults include vibration analysis, thermal imaging, and ultrasonic testing, which identify issues such as bearing wear or misalignment. Electrical fault diagnosis relies on tools like multimeters, oscilloscopes, and insulation testers to detect wiring problems, short circuits, or component failures. Combining these diagnostic methods ensures precise identification and faster repair of complex systems with both mechanical and electrical components.

Tools Required for Mechanical vs Electrical Repairs

Mechanical repairs typically require tools such as wrenches, screwdrivers, hammers, torque wrenches, and socket sets to handle nuts, bolts, and moving parts. Electrical repairs demand specialized equipment like multimeters, wire strippers, insulated screwdrivers, circuit testers, and soldering irons to safely diagnose and fix wiring, connectors, and circuits. Proper tool selection ensures efficiency and safety when addressing mechanical or electrical issues in various systems.

Cost Comparison: Mechanical vs Electrical Fixes

Mechanical repairs typically involve components such as gears, belts, and bearings, often requiring more labor-intensive processes that drive up costs. Electrical fixes usually focus on wiring, circuit boards, and control units, which can be more expensive due to the need for specialized diagnostic tools and replacement parts. Cost comparison reveals mechanical repairs tend to have lower parts costs but higher labor hours, while electrical fixes incur higher parts expenses but may require less labor time.

Safety Considerations in Mechanical and Electrical Repairs

Mechanical repairs often involve handling heavy tools and moving parts, necessitating strict adherence to personal protective equipment (PPE) like gloves and eye protection to prevent physical injuries. Electrical repairs pose significant risks of electric shock, burns, and fires, making it essential to disconnect power sources and use insulated tools to ensure safety. Implementing lockout-tagout (LOTO) procedures and verifying the absence of voltage before beginning electrical work significantly reduce the chances of accidents.

When to DIY or Call a Professional: Mechanical vs Electrical

Mechanical repairs such as tightening bolts, replacing belts, or fixing leaks can often be handled by DIY enthusiasts with basic tools and safety knowledge, while electrical fixes involving wiring, circuit breakers, or complex appliances require professional expertise due to safety risks and code regulations. Assess the complexity and potential hazards of the task before proceeding, as improper electrical work can lead to fire hazards or electrocution, making licensed electricians the safest option. Mechanical issues generally pose fewer risks and are more accessible for DIY solutions, but electrical problems demand strict adherence to safety standards and specialized skills.

Preventive Maintenance: Reducing Mechanical and Electrical Issues

Preventive maintenance significantly reduces mechanical and electrical failures by identifying potential issues before they escalate, extending equipment lifespan and improving system reliability. Mechanical fixes often address wear and tear in moving parts such as bearings and belts, while electrical fixes focus on preventing circuit failures and insulation breakdown. Implementing scheduled inspections and routine servicing minimizes downtime and lowers overall repair costs in industrial environments.

mechanical fix vs electrical fix Infographic

cardiffo.com

cardiffo.com