Refurbished parts undergo thorough inspection, cleaning, and minor repairs to restore functionality, while remanufactured parts are rebuilt to meet original equipment manufacturer (OEM) specifications through extensive disassembly and replacement of worn components. Refurbished parts offer a cost-effective solution with reasonable reliability, but remanufactured parts provide higher durability and performance consistency due to their rigorous restoration process. Choosing between refurbished and remanufactured parts depends on the balance between budget constraints and the desired lifespan or warranty coverage for the repair.

Table of Comparison

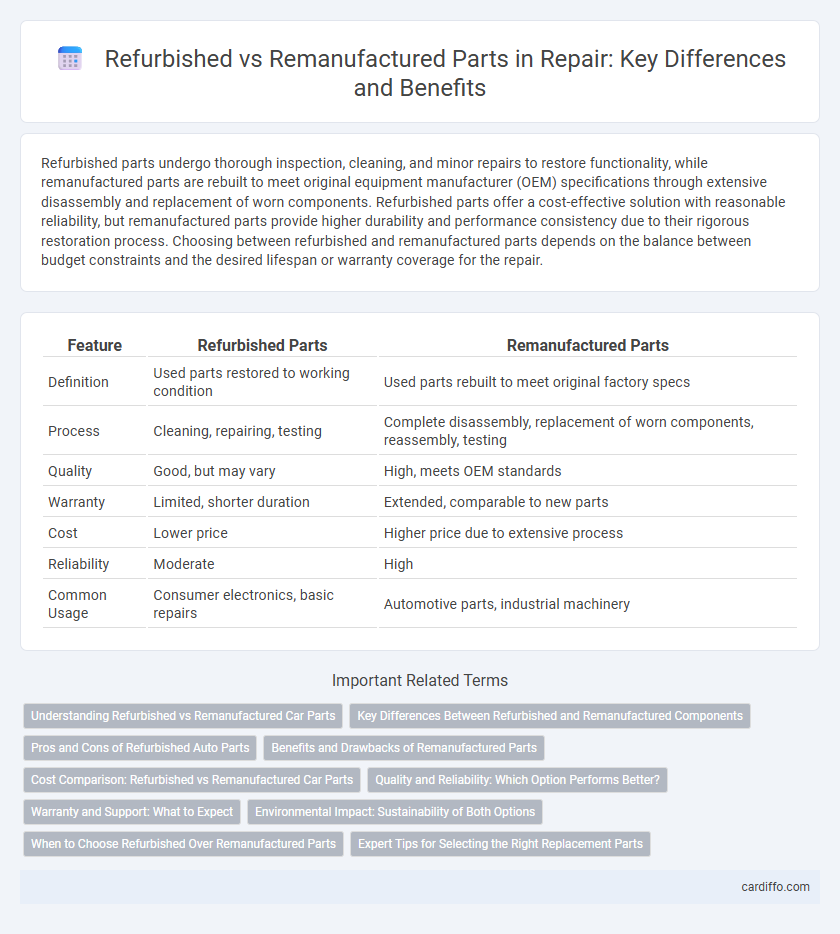

| Feature | Refurbished Parts | Remanufactured Parts |

|---|---|---|

| Definition | Used parts restored to working condition | Used parts rebuilt to meet original factory specs |

| Process | Cleaning, repairing, testing | Complete disassembly, replacement of worn components, reassembly, testing |

| Quality | Good, but may vary | High, meets OEM standards |

| Warranty | Limited, shorter duration | Extended, comparable to new parts |

| Cost | Lower price | Higher price due to extensive process |

| Reliability | Moderate | High |

| Common Usage | Consumer electronics, basic repairs | Automotive parts, industrial machinery |

Understanding Refurbished vs Remanufactured Car Parts

Refurbished car parts are used components restored to working condition through cleaning, repairing, and testing, often retaining some original wear, while remanufactured parts are completely rebuilt to meet or exceed OEM specifications with new components and rigorous quality control. Choosing remanufactured parts ensures higher reliability and longer lifespan due to strict adherence to factory standards compared to refurbished parts, which may vary in quality depending on the restoration process. Ultimately, understanding these distinctions helps buyers make informed decisions for car repairs, balancing cost and performance needs.

Key Differences Between Refurbished and Remanufactured Components

Refurbished parts are used components restored to functional condition through cleaning, repairing, and testing, often with no guarantee of meeting original factory specifications. Remanufactured parts undergo a more rigorous process involving complete disassembly, replacement of worn components, and reassembly to meet or exceed OEM standards, ensuring higher reliability and performance. The key differences lie in the extent of restoration, quality assurance, and warranty coverage, with remanufactured parts offering more consistency and longer lifespan than refurbished ones.

Pros and Cons of Refurbished Auto Parts

Refurbished auto parts offer a cost-effective alternative to new components, providing savings of up to 40% while restoring functionality through cleaning, repairing, and testing. These parts may have variable quality and shorter warranties compared to remanufactured parts, which undergo complete disassembly and replacement of worn components. Consumers benefit from lower prices and quicker availability but face potential risks regarding durability and performance consistency.

Benefits and Drawbacks of Remanufactured Parts

Remanufactured parts offer the benefit of restoring components to like-new condition through rigorous processes including disassembly, cleaning, replacement of worn parts, and testing, ensuring high reliability and performance. These parts often come with warranties, providing assurance and extending the lifespan of machinery or vehicles, which can result in significant cost savings compared to new parts. However, remanufactured parts may have limited availability for certain models and their quality can vary depending on the remanufacturer's standards, potentially leading to inconsistencies in performance or fit.

Cost Comparison: Refurbished vs Remanufactured Car Parts

Refurbished car parts generally cost 30-50% less than remanufactured parts due to minimal processing, often involving cleaning and minor repairs only. Remanufactured parts undergo extensive reengineering and testing, resulting in higher reliability but a price premium typically 20-40% above refurbished options. Choosing between the two depends on budget constraints and desired part longevity, with refurbished parts offering savings and remanufactured parts providing near-new performance.

Quality and Reliability: Which Option Performs Better?

Refurbished parts undergo inspection, cleaning, and minor repairs to restore functionality but may retain some wear, impacting long-term reliability. Remanufactured parts are rebuilt to meet original equipment manufacturer (OEM) standards through comprehensive testing and replacement of worn components, resulting in higher quality and consistent performance. Studies indicate remanufactured parts typically offer superior durability and performance, making them a more reliable choice for repair solutions.

Warranty and Support: What to Expect

Refurbished parts typically come with limited warranties ranging from 30 to 90 days, reflecting their repaired condition and potential variability in lifespan. Remanufactured parts offer more comprehensive warranties comparable to new products, often extending up to 12 months or more, ensuring higher reliability and manufacturer support. Support for remanufactured components is generally more robust, including access to technical assistance and replacement guarantees, while refurbished parts may have restricted service options.

Environmental Impact: Sustainability of Both Options

Refurbished parts typically involve repairing and testing used components to extend their lifespan, which reduces waste and conserves resources but may have variable environmental benefits depending on the extent of restoration. Remanufactured parts are rebuilt to meet original equipment manufacturer (OEM) standards, ensuring higher durability and performance while promoting circular economy principles by significantly lowering raw material extraction and energy consumption. Both options contribute to sustainability by minimizing landfill waste and carbon emissions, though remanufacturing generally offers a more consistent and impactful reduction in environmental footprint.

When to Choose Refurbished Over Remanufactured Parts

Refurbished parts are ideal when cost savings and faster turnaround are priorities, as they typically undergo cosmetic repairs and basic functionality testing without full disassembly. Choose refurbished parts for less critical applications or older equipment where perfect component precision is less essential. This approach balances quality and affordability, especially when the budget limits full remanufacturing processes.

Expert Tips for Selecting the Right Replacement Parts

When selecting replacement parts, experts recommend understanding the distinction between refurbished and remanufactured components, as refurbished parts are repaired to working condition but may have prior wear, while remanufactured parts undergo extensive rebuilding to meet original manufacturer specifications. Evaluate the warranty terms and supplier credibility to ensure reliability and performance that align with the vehicle's requirements. Prioritize parts with documented testing and quality assurance certifications to optimize the longevity and safety of repairs.

Refurbished parts vs remanufactured parts Infographic

cardiffo.com

cardiffo.com