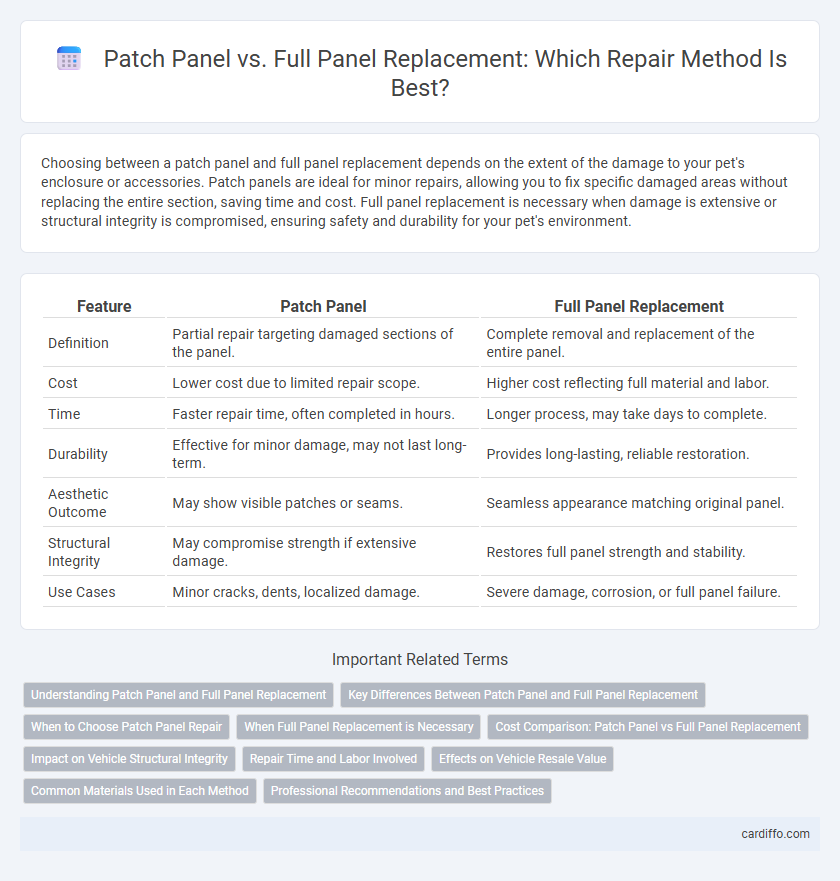

Choosing between a patch panel and full panel replacement depends on the extent of the damage to your pet's enclosure or accessories. Patch panels are ideal for minor repairs, allowing you to fix specific damaged areas without replacing the entire section, saving time and cost. Full panel replacement is necessary when damage is extensive or structural integrity is compromised, ensuring safety and durability for your pet's environment.

Table of Comparison

| Feature | Patch Panel | Full Panel Replacement |

|---|---|---|

| Definition | Partial repair targeting damaged sections of the panel. | Complete removal and replacement of the entire panel. |

| Cost | Lower cost due to limited repair scope. | Higher cost reflecting full material and labor. |

| Time | Faster repair time, often completed in hours. | Longer process, may take days to complete. |

| Durability | Effective for minor damage, may not last long-term. | Provides long-lasting, reliable restoration. |

| Aesthetic Outcome | May show visible patches or seams. | Seamless appearance matching original panel. |

| Structural Integrity | May compromise strength if extensive damage. | Restores full panel strength and stability. |

| Use Cases | Minor cracks, dents, localized damage. | Severe damage, corrosion, or full panel failure. |

Understanding Patch Panel and Full Panel Replacement

Understanding patch panel repair involves addressing localized damage or faults by replacing only the affected section, which saves time and cost compared to full panel replacement. Full panel replacement is necessary when widespread corrosion, severe structural damage, or multiple failures compromise the entire panel's integrity and safety. Evaluating the extent of damage through diagnostic tests and visual inspection determines whether a targeted patch repair or a complete panel overhaul is the most effective solution.

Key Differences Between Patch Panel and Full Panel Replacement

Patch panel repair targets specific damaged sections, enabling localized fixes without dismantling the entire system, which reduces downtime and cost. Full panel replacement involves removing and installing an entirely new panel, providing a comprehensive solution for extensive damage or when upgrading outdated infrastructure. Choosing between patch panel and full panel replacement depends on the damage severity, budget constraints, and long-term reliability requirements.

When to Choose Patch Panel Repair

Patch panel repair is ideal when damage is localized, minimizing downtime and reducing costs compared to full panel replacement. Technicians should opt for patch panel repair when the surrounding infrastructure remains intact and the issue involves isolated faults such as broken ports or connectors. This approach extends the lifespan of the existing system while maintaining network performance without the expense of complete panel replacement.

When Full Panel Replacement is Necessary

Full panel replacement is necessary when the patch panel shows extensive physical damage, such as cracked or broken ports, or when multiple ports fail simultaneously, compromising network reliability. Severe corrosion or wear that impedes proper cable connection or causes frequent signal loss also warrants a full panel replacement. Choosing a full replacement ensures long-term stability and reduces maintenance costs compared to repeated patching of damaged sections.

Cost Comparison: Patch Panel vs Full Panel Replacement

Patch panel replacement typically costs significantly less than a full panel replacement, often saving 50% to 70% due to lower labor and material expenses. Full panel replacement involves higher costs from complete dismantling, ordering a new panel, and extended labor time, which can double or triple the repair budget. Evaluating the extent of damage and electrical safety codes helps determine the more cost-effective option between patching and full replacement.

Impact on Vehicle Structural Integrity

Patch panel repair preserves the original structural components of a vehicle, maintaining its factory-designed strength and alignment. Full panel replacement can restore damaged areas but risks altering the vehicle's structural integrity if not executed with precise fitment and welding techniques. Choosing patch panels tends to result in better retention of crashworthiness and overall vehicle safety.

Repair Time and Labor Involved

Patch panel repair typically requires less time, often completed within a few hours, as it involves replacing only the damaged section rather than the entire assembly. Labor involved in patch panel repair is generally less intensive, minimizing downtime and reducing overall costs. In contrast, full panel replacement demands more extensive labor and longer repair time, as the entire panel must be removed, installed, and reconfigured, making it a more complex and time-consuming process.

Effects on Vehicle Resale Value

Choosing patch panel repair over a full panel replacement can preserve more original factory metal, often maintaining higher resale value due to authentic structural integrity. Full panel replacements may sometimes lead to concerns about the quality of repairs and potential misalignment, which can reduce buyer confidence and lower market value. Vehicle history reports and professional repair certifications play crucial roles in validating the quality of repairs and influencing resale price.

Common Materials Used in Each Method

Patch panels commonly utilize materials such as modular plastic casings and copper or aluminum contacts for efficient connectivity and cost-effective repairs. Full panel replacements often involve sturdier materials like steel or reinforced aluminum to ensure durability and structural integrity in heavy-duty applications. Selecting between these methods depends on the repair scope, with patch panels suited for minor damage and full replacements preferred for extensive wear or corrosion.

Professional Recommendations and Best Practices

Professional recommendations emphasize assessing the extent of damage before deciding between patch panel and full panel replacement, as patching is suitable for localized corrosion or minor dents, while full replacement provides comprehensive structural integrity for extensive damage. Best practices include thorough inspection, surface preparation, and proper alignment to ensure optimal adhesion and durability in patch repairs, whereas full panel replacement requires precise welding and seamless integration to maintain factory specifications. Technicians prioritize cost-effectiveness and long-term reliability, often favoring full panel replacement for safety-critical areas despite higher labor intensity.

Patch Panel vs Full Panel Replacement Infographic

cardiffo.com

cardiffo.com