Patch repairs involve applying a replacement piece of material over a damaged area, offering a quick and cost-effective solution for minor surface defects. Welding fuses two metal pieces together, providing a strong, durable bond ideal for structural damage or deeper cracks. Choosing between patch and weld depends on the extent of damage, material type, and desired repair longevity.

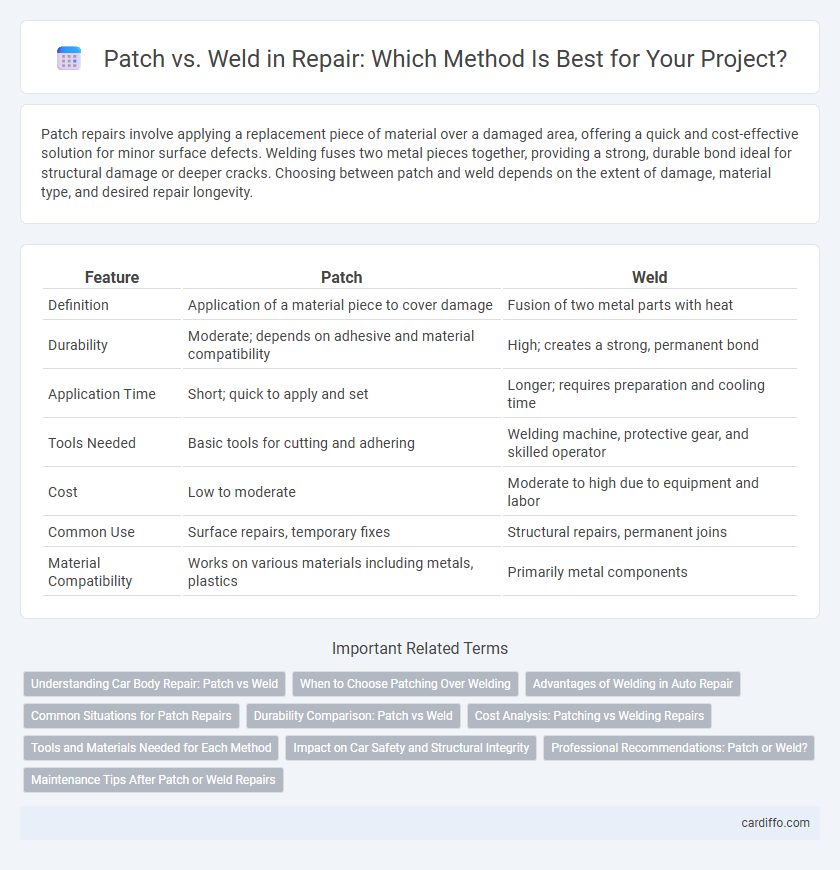

Table of Comparison

| Feature | Patch | Weld |

|---|---|---|

| Definition | Application of a material piece to cover damage | Fusion of two metal parts with heat |

| Durability | Moderate; depends on adhesive and material compatibility | High; creates a strong, permanent bond |

| Application Time | Short; quick to apply and set | Longer; requires preparation and cooling time |

| Tools Needed | Basic tools for cutting and adhering | Welding machine, protective gear, and skilled operator |

| Cost | Low to moderate | Moderate to high due to equipment and labor |

| Common Use | Surface repairs, temporary fixes | Structural repairs, permanent joins |

| Material Compatibility | Works on various materials including metals, plastics | Primarily metal components |

Understanding Car Body Repair: Patch vs Weld

Car body repair involves choosing between patching and welding based on damage severity and location. Patch repair uses pre-cut metal pieces to cover holes or rust spots, offering a quicker, cost-effective solution for minor damage. Welding fuses metal parts together, providing stronger, more durable repairs essential for structural integrity in major collision repairs.

When to Choose Patching Over Welding

Patching is ideal when repairing localized surface damage or holes without compromising the structural integrity of the entire component. It offers a quicker, more cost-effective solution for minor defects where full welding might be excessive or risk heat distortion. Choose patching over welding for corrosion spots, small cracks, or thin metal areas sensitive to heat input.

Advantages of Welding in Auto Repair

Welding in auto repair offers superior strength and durability compared to patching, ensuring long-lasting structural integrity in vehicle frames. It enables precise joining of metal components, providing a seamless finish that restores original safety standards. Welding also allows for customized repairs on complex or damaged areas, which patching methods cannot adequately address.

Common Situations for Patch Repairs

Patch repairs are commonly used for fixing localized damage such as cracks, holes, or corrosion on metal surfaces. They offer a quick and cost-effective solution for areas where structural integrity is not severely compromised. Typical situations include automotive bodywork, ship hull maintenance, and HVAC duct fixing, where welding may be impractical or unnecessary.

Durability Comparison: Patch vs Weld

Patching provides a quick repair solution but often lacks the long-term durability of welding, which fuses materials together for enhanced strength and resistance to stress. Welded repairs generally withstand higher loads and environmental challenges, making them suitable for structural applications requiring longevity. In contrast, patches may degrade faster under mechanical strain or exposure to harsh conditions, necessitating more frequent maintenance or replacement.

Cost Analysis: Patching vs Welding Repairs

Patching repairs generally incur lower immediate costs due to minimal labor and materials, making them suitable for quick fixes and smaller damages. Welding repairs, while often more expensive upfront due to specialized skills and equipment, provide stronger, longer-lasting structural integrity that reduces future maintenance expenses. Evaluating overall cost efficiency requires analyzing repair size, expected lifespan, and potential downtime to determine the most economical solution between patching and welding.

Tools and Materials Needed for Each Method

Patch repair requires tools such as metal shears, clamps, a drill, and rivets or bolts, along with sheet metal or composite patches as materials. Welding demands equipment like a welding machine, protective helmet, welding rods or wire, and shielding gas, with various metals such as steel, aluminum, or stainless steel serving as the base material. Each method necessitates specific tools and materials tailored to the repair type, ensuring structural integrity and durability.

Impact on Car Safety and Structural Integrity

Patching a damaged area provides a quick fix but may compromise the car's safety and structural integrity if not properly reinforced, potentially leading to weaker crash resistance. Welding restores the frame or body panel by fusing metal parts together, offering superior strength and durability critical for maintaining the vehicle's original safety standards. Properly executed welding ensures the structural components function as designed, preserving crash protection and overall vehicle stability.

Professional Recommendations: Patch or Weld?

Professional recommendations for repair methods prioritize patching when addressing surface-level damage or minor defects, as it preserves the base material and reduces the risk of heat distortion. Welding is advised for structural repairs requiring full penetration and strength restoration, especially on load-bearing components. Experts emphasize evaluating factors such as material type, damage extent, and intended use to determine the optimal repair approach.

Maintenance Tips After Patch or Weld Repairs

Regular inspection of patch and weld repairs is crucial to ensure structural integrity and early detection of cracks or corrosion. Applying anti-corrosion coatings and maintaining appropriate environmental conditions significantly extend the lifespan of repairs. Scheduling routine maintenance based on the material type and stress exposure helps prevent unexpected failures in patched or welded areas.

Patch vs Weld Infographic

cardiffo.com

cardiffo.com