R12 refrigerant, once widely used in automotive and refrigeration systems, has been phased out due to its high ozone depletion potential and environmental regulations. R134a refrigerant serves as a common replacement, offering improved environmental safety with lower ozone impact and comparable cooling performance. When repairing systems originally designed for R12, proper retrofitting and compatibility checks with R134a are essential to ensure efficient and safe operation.

Table of Comparison

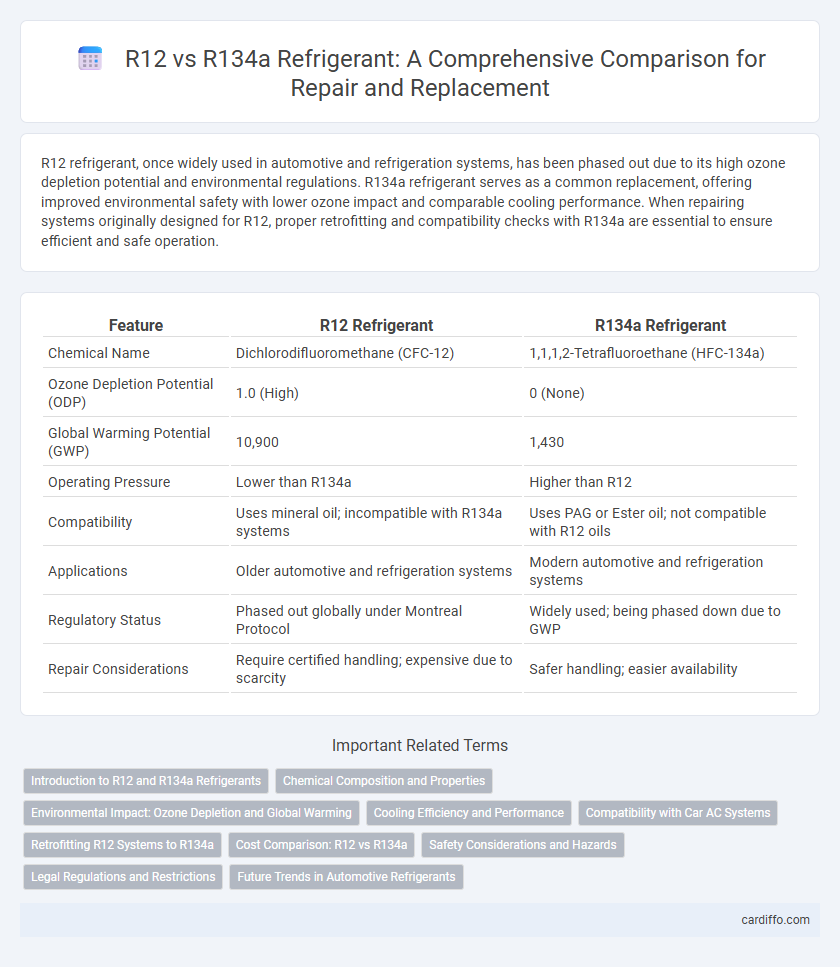

| Feature | R12 Refrigerant | R134a Refrigerant |

|---|---|---|

| Chemical Name | Dichlorodifluoromethane (CFC-12) | 1,1,1,2-Tetrafluoroethane (HFC-134a) |

| Ozone Depletion Potential (ODP) | 1.0 (High) | 0 (None) |

| Global Warming Potential (GWP) | 10,900 | 1,430 |

| Operating Pressure | Lower than R134a | Higher than R12 |

| Compatibility | Uses mineral oil; incompatible with R134a systems | Uses PAG or Ester oil; not compatible with R12 oils |

| Applications | Older automotive and refrigeration systems | Modern automotive and refrigeration systems |

| Regulatory Status | Phased out globally under Montreal Protocol | Widely used; being phased down due to GWP |

| Repair Considerations | Require certified handling; expensive due to scarcity | Safer handling; easier availability |

Introduction to R12 and R134a Refrigerants

R12 refrigerant, also known as dichlorodifluoromethane, was widely used in automotive and refrigeration systems due to its excellent thermodynamic properties but has been phased out because of its ozone-depleting effects. R134a refrigerant, or tetrafluoroethane, serves as a more environmentally friendly alternative with zero ozone depletion potential and improved compatibility with modern refrigeration oils. The transition from R12 to R134a reflects regulatory shifts aimed at reducing environmental impact while maintaining effective cooling performance in HVAC and automotive applications.

Chemical Composition and Properties

R12 refrigerant, chemically known as dichlorodifluoromethane (CCl2F2), belongs to the chlorofluorocarbon (CFC) family and has a higher ozone depletion potential compared to R134a. R134a, or 1,1,1,2-tetrafluoroethane (C2H2F4), is a hydrofluorocarbon (HFC) with zero ozone depletion potential and improved thermal stability. The differing chemical compositions lead to variations in boiling points, pressure, and environmental impact, influencing their use in automotive air conditioning and refrigeration systems.

Environmental Impact: Ozone Depletion and Global Warming

R12 refrigerant contains chlorofluorocarbons (CFCs) that cause significant ozone layer depletion and have a high global warming potential (GWP) of about 10,900. In contrast, R134a refrigerant is a hydrofluorocarbon (HFC) with zero ozone depletion potential (ODP) and a much lower GWP of approximately 1,430, making it less harmful to the environment. The phase-out of R12 in favor of R134a reflects efforts to reduce ozone damage and mitigate climate change caused by refrigerant emissions.

Cooling Efficiency and Performance

R12 refrigerant offers higher cooling efficiency due to its superior thermodynamic properties, enabling faster cooling cycles and better heat absorption compared to R134a. However, R134a is widely adopted for its improved environmental performance, featuring lower ozone depletion potential and acceptable cooling capacity in modern air conditioning systems. Despite its slightly reduced efficiency, R134a maintains reliable overall performance and energy consumption, making it a common replacement for R12 in automotive and refrigeration applications.

Compatibility with Car AC Systems

R12 refrigerant is incompatible with most modern car AC systems designed for R134a due to differences in chemical composition and operating pressure. R134a requires specific seals, lubricants, and system components that cannot be used interchangeably with R12 systems. Converting an R12 system to R134a involves replacing hoses, compressors, and seals to prevent leaks and ensure optimal air conditioning performance.

Retrofitting R12 Systems to R134a

Retrofitting R12 systems to R134a refrigerant requires replacing seals, oils, and possibly the receiver-drier to accommodate R134a's chemical properties and prevent leaks. R134a operates at higher pressures than R12, demanding system components compatible with increased stress levels and ensuring optimal cooling efficiency. Proper flushing of the system and thorough leak testing are essential steps to maintain performance and avoid contamination during the retrofit process.

Cost Comparison: R12 vs R134a

R12 refrigerant typically costs more due to its phase-out status and limited availability from environmental regulations. R134a is generally more affordable and widely accessible, reflecting its status as the preferred replacement that meets current environmental standards. Maintenance and repair costs also favor R134a, as its compatibility with modern systems reduces long-term expenses compared to the increasingly scarce R12.

Safety Considerations and Hazards

R12 refrigerant poses significant health and environmental hazards due to its ozone-depleting properties and high toxicity, requiring careful handling with protective equipment and proper ventilation. R134a, a hydrofluorocarbon, is non-ozone depleting and has lower toxicity, but it is still flammable in certain concentrations and can cause frostbite or respiratory issues if released during repair. Safe disposal and recovery procedures are critical for both refrigerants to prevent environmental contamination and ensure technician safety during HVAC system maintenance.

Legal Regulations and Restrictions

R12 refrigerant is banned in many countries due to its ozone-depleting properties under the Montreal Protocol, making its use in automotive and refrigeration systems illegal or highly restricted. R134a refrigerant, which has a lower environmental impact, is widely accepted and regulated as a safer alternative but is subject to phase-down policies due to its global warming potential. Compliance with environmental laws requires technicians and service centers to use certified recovery and recycling methods for both refrigerants during repair and maintenance.

Future Trends in Automotive Refrigerants

R134a refrigerant, phased out due to high global warming potential (GWP), is being replaced by R1234yf and other low-GWP alternatives in automotive air conditioning systems, aligning with stricter environmental regulations. R12 refrigerant, obsolete and banned worldwide for ozone depletion, remains a reference point in the evolution toward environmentally friendly refrigerants. Future trends favor refrigerants with minimal environmental impact, enhanced energy efficiency, and compliance with international climate agreements such as the Kigali Amendment.

R12 refrigerant vs R134a refrigerant Infographic

cardiffo.com

cardiffo.com