Resurfacing rotors involves machining the existing surface to remove imperfections and restore smoothness, which can extend the life of the rotors at a lower cost compared to replacement. However, resurfacing is only viable if the rotors have sufficient thickness and no deep cracks or significant damage are present. Replacing rotors provides a more reliable and safer solution when wear, warping, or structural issues exceed repair limits, ensuring optimal braking performance and longevity.

Table of Comparison

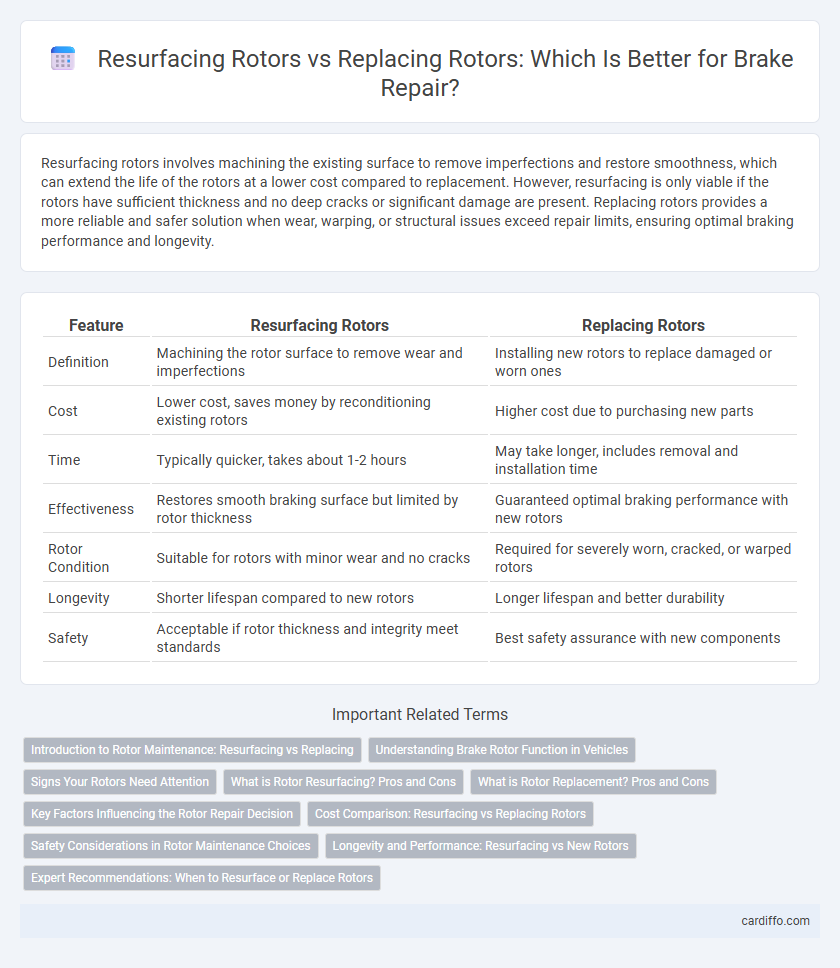

| Feature | Resurfacing Rotors | Replacing Rotors |

|---|---|---|

| Definition | Machining the rotor surface to remove wear and imperfections | Installing new rotors to replace damaged or worn ones |

| Cost | Lower cost, saves money by reconditioning existing rotors | Higher cost due to purchasing new parts |

| Time | Typically quicker, takes about 1-2 hours | May take longer, includes removal and installation time |

| Effectiveness | Restores smooth braking surface but limited by rotor thickness | Guaranteed optimal braking performance with new rotors |

| Rotor Condition | Suitable for rotors with minor wear and no cracks | Required for severely worn, cracked, or warped rotors |

| Longevity | Shorter lifespan compared to new rotors | Longer lifespan and better durability |

| Safety | Acceptable if rotor thickness and integrity meet standards | Best safety assurance with new components |

Introduction to Rotor Maintenance: Resurfacing vs Replacing

Rotors, an essential component of the braking system, require regular maintenance to ensure optimal performance and safety. Resurfacing rotors involves machining the existing surface to remove imperfections and restore smoothness, which can extend rotor life if thickness standards are maintained. Replacing rotors is necessary when wear exceeds safety limits, warping occurs, or damage is too severe, guaranteeing reliable braking and preventing further system issues.

Understanding Brake Rotor Function in Vehicles

Brake rotors play a critical role in vehicle braking systems by providing a surface for brake pads to clamp down on, creating friction that slows the wheel's rotation. Resurfacing rotors restores a smooth, even surface that can extend rotor life and improve braking performance when minimal wear or damage is present. Replacing rotors is necessary when rotors are excessively worn, warped, or below minimum thickness specifications, ensuring safe and effective braking operation.

Signs Your Rotors Need Attention

Worn, warped, or scored rotors often cause vibrations or pulsations during braking, signaling the need for repair. Deep grooves or excessive thickness variation can be measured with a micrometer, indicating whether resurfacing is feasible or replacement is necessary. Persistent brake noise, diminished stopping power, and visible rotor damage are critical indicators that rotors require professional inspection to determine the best course of action.

What is Rotor Resurfacing? Pros and Cons

Rotor resurfacing involves machining the surface of brake rotors to remove grooves, corrosion, and uneven wear, restoring a smooth braking surface. Pros include cost savings compared to full replacement and extending rotor life while maintaining safe braking performance, but cons involve potential rotor weakening, limited resurfacing thickness, and the risk of reduced heat dissipation leading to brake fade. This method is ideal when rotors are still within manufacturer thickness limits and free from severe damage or warping.

What is Rotor Replacement? Pros and Cons

Rotor replacement involves removing the worn or damaged brake rotors and installing new ones to restore optimal braking performance. Pros include improved safety, enhanced braking efficiency, and long-term durability, while cons involve higher initial costs and longer repair time compared to rotor resurfacing. This option is often recommended when rotors are severely warped, cracked, or below the minimum thickness specified by the manufacturer.

Key Factors Influencing the Rotor Repair Decision

Resurfacing rotors is recommended when the rotor has minor surface imperfections and sufficient thickness to maintain structural integrity, ensuring cost-effective brake performance restoration. Replacing rotors becomes necessary when there is deep scoring, warping, or the rotor thickness falls below the manufacturer's minimum specification, which compromises safety and braking efficiency. Factors such as rotor condition, vehicle type, cost considerations, and brake system compatibility are critical in deciding between resurfacing and replacing rotors.

Cost Comparison: Resurfacing vs Replacing Rotors

Resurfacing rotors typically costs between $10 to $40 per rotor, making it a budget-friendly option when the rotor is only slightly worn or warped. Replacing rotors can range from $30 to $75 per rotor for standard quality, with premium or performance rotors reaching $100 or more, factoring in labor costs up to $150 per axle. Cost comparison reveals that resurfacing offers immediate savings but risks reduced rotor lifespan, while replacing ensures optimal performance and longevity at a higher upfront expense.

Safety Considerations in Rotor Maintenance Choices

Resurfacing rotors can save costs while maintaining adequate braking performance, but worn or warped rotors may compromise vehicle safety and require replacement to ensure optimal stopping power. Choosing replacement rotors eliminates the risk of compromised metal integrity caused by repeated resurfacing, significantly reducing brake fade and vibration during critical braking situations. Safety considerations demand strict adherence to manufacturer specifications, as improper rotor maintenance can lead to reduced friction efficiency and increased accident risk.

Longevity and Performance: Resurfacing vs New Rotors

Resurfacing rotors extends their usability by restoring a smooth surface, but may reduce overall thickness and compromise longevity compared to new rotors. New rotors guarantee optimal performance, heat dissipation, and structural integrity, ensuring consistent braking efficiency over a longer lifespan. Choosing replacement over resurfacing is crucial for maintaining safety and avoiding warping or brake fade under heavy use.

Expert Recommendations: When to Resurface or Replace Rotors

Experts recommend resurfacing rotors only when the surface is uneven but the thickness remains within manufacturer specifications, ensuring safe braking performance. Replacing rotors is advised when deep grooves, warping, or thickness below the minimum threshold compromises structural integrity and safety. Advanced diagnostic tools and manufacturer guidelines help technicians determine the optimal choice between resurfacing and replacement for reliable vehicle braking.

Resurfacing rotors vs replacing rotors Infographic

cardiffo.com

cardiffo.com