Hand sanding allows for precise control and is ideal for delicate surfaces or intricate details, ensuring a smooth, customized finish. Machine sanding covers larger areas quickly, boosting efficiency and providing consistent results on flat, extensive surfaces. Choosing between hand sanding and machine sanding depends on the project's size, surface complexity, and desired finish quality.

Table of Comparison

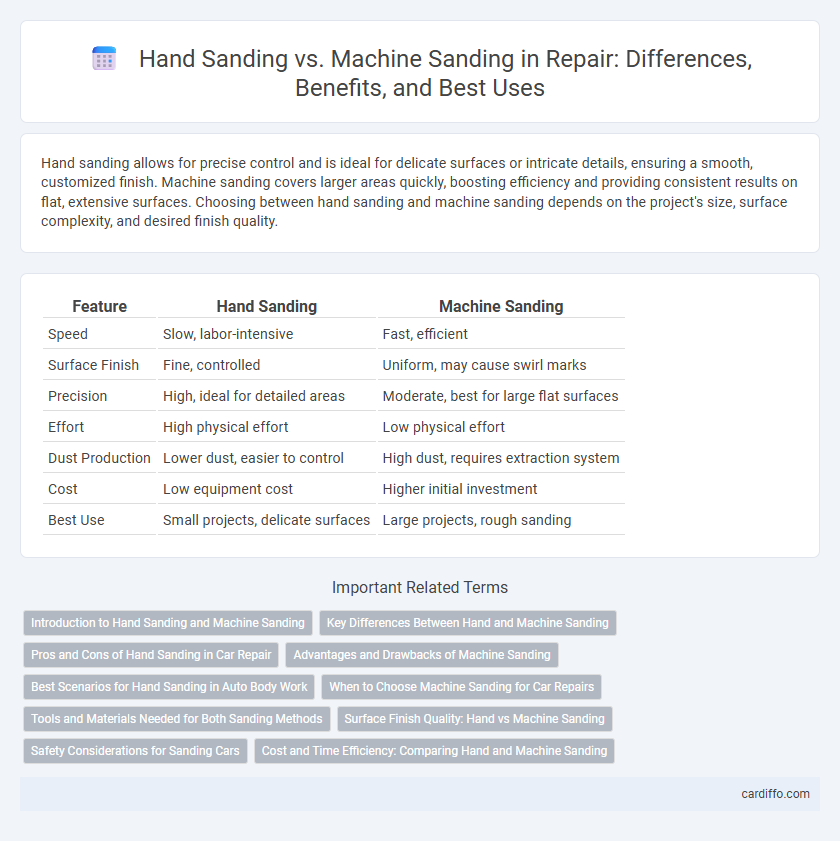

| Feature | Hand Sanding | Machine Sanding |

|---|---|---|

| Speed | Slow, labor-intensive | Fast, efficient |

| Surface Finish | Fine, controlled | Uniform, may cause swirl marks |

| Precision | High, ideal for detailed areas | Moderate, best for large flat surfaces |

| Effort | High physical effort | Low physical effort |

| Dust Production | Lower dust, easier to control | High dust, requires extraction system |

| Cost | Low equipment cost | Higher initial investment |

| Best Use | Small projects, delicate surfaces | Large projects, rough sanding |

Introduction to Hand Sanding and Machine Sanding

Hand sanding allows precise control for delicate surfaces and intricate details, using sandpaper sheets or sanding blocks to manually smooth wood, metal, or painted surfaces. Machine sanding employs power tools like orbital sanders and belt sanders, offering faster material removal and consistent finishes on larger areas. Choosing between hand sanding and machine sanding depends on project scale, surface complexity, and desired finish quality.

Key Differences Between Hand and Machine Sanding

Hand sanding offers precise control for delicate or detailed surfaces, allowing targeted smoothing and fine finishing. Machine sanding delivers faster material removal with consistent results on larger areas, reducing labor time significantly. The choice depends on project scale, surface complexity, and desired finish quality, balancing speed against accuracy.

Pros and Cons of Hand Sanding in Car Repair

Hand sanding in car repair offers precise control for detailed areas and delicate finishes, reducing the risk of removing too much material. It is cost-effective and requires minimal equipment, making it accessible for small repairs or touch-ups. However, hand sanding is labor-intensive and time-consuming compared to machine sanding, and it may result in inconsistencies in smoothness and surface uniformity.

Advantages and Drawbacks of Machine Sanding

Machine sanding offers faster material removal and consistent surface finish, making it ideal for large projects and rough surfaces. It may cause overheating or uneven sanding if not properly controlled, potentially damaging delicate materials. Noise level and dust generation are higher compared to hand sanding, requiring protective measures for safety and cleanliness.

Best Scenarios for Hand Sanding in Auto Body Work

Hand sanding excels in auto body work for detailed areas, edges, and curved surfaces where precision is critical and machine sanding could cause damage. It provides better control for feathering paint transitions, smoothing small imperfections, and preparing complex contours for primer or paint. This method is ideal when working on tight spots or final finishing stages to achieve a flawless surface texture.

When to Choose Machine Sanding for Car Repairs

Machine sanding is best suited for large surface areas or when extensive paint removal is required during car repairs, ensuring uniform finish and efficiency. It is ideal for smoothing out major imperfections and preparing broad panels for repainting, reducing labor time significantly compared to hand sanding. Use machine sanding when precision and speed are critical, especially on flat or gently curved surfaces where consistent abrasion is necessary.

Tools and Materials Needed for Both Sanding Methods

Hand sanding requires sandpaper sheets or sanding blocks in various grits, a sanding sponge, and sometimes a sanding sealer to prepare surfaces smoothly. Machine sanding uses power sanders like orbital, belt, or detail sanders, along with compatible sanding discs or belts designed for specific grit levels and materials, often paired with dust collection systems to minimize debris. Both methods may require protective gear such as gloves, masks, and safety glasses to ensure operator safety and achieve optimal surface finish.

Surface Finish Quality: Hand vs Machine Sanding

Hand sanding offers precise control, allowing for a smoother finish on delicate or intricate surfaces by minimizing the risk of over-sanding and preserving fine details. Machine sanding provides faster material removal and consistent results on large or flat surfaces but may cause uneven finishes or swirl marks if not properly managed. Selecting between hand and machine sanding depends on the desired surface finish quality, project scale, and material sensitivity.

Safety Considerations for Sanding Cars

Hand sanding a car offers greater control and reduces the risk of damaging delicate areas, minimizing dust inhalation when used with proper masks and ventilation. Machine sanding increases efficiency but requires careful handling to avoid burns or removing too much material, alongside wearing protective eyewear and respirators to protect against airborne particles. Choosing the right abrasive grit and sanding speed improves safety by preventing surface overheating and ensuring a smooth finish.

Cost and Time Efficiency: Comparing Hand and Machine Sanding

Hand sanding offers lower upfront costs but demands more time and labor, making it less efficient for large-scale projects. Machine sanding, while requiring investment in equipment, significantly reduces labor hours and speeds up the process, resulting in greater overall cost-effectiveness for extensive repairs. Choosing between methods depends on project size, budget constraints, and desired finish quality.

Hand sanding vs Machine sanding Infographic

cardiffo.com

cardiffo.com