Mechanical fuel pumps operate using engine-driven mechanisms, providing fuel at lower pressure ideal for carbureted engines, while electric fuel pumps deliver consistent high pressure suitable for fuel-injected systems. Electric fuel pumps offer better efficiency and reliability, often located inside the fuel tank to reduce vapor lock and improve cooling. Choosing between the two depends on the engine type and performance requirements, with electric pumps favored in modern vehicles for their precision and durability.

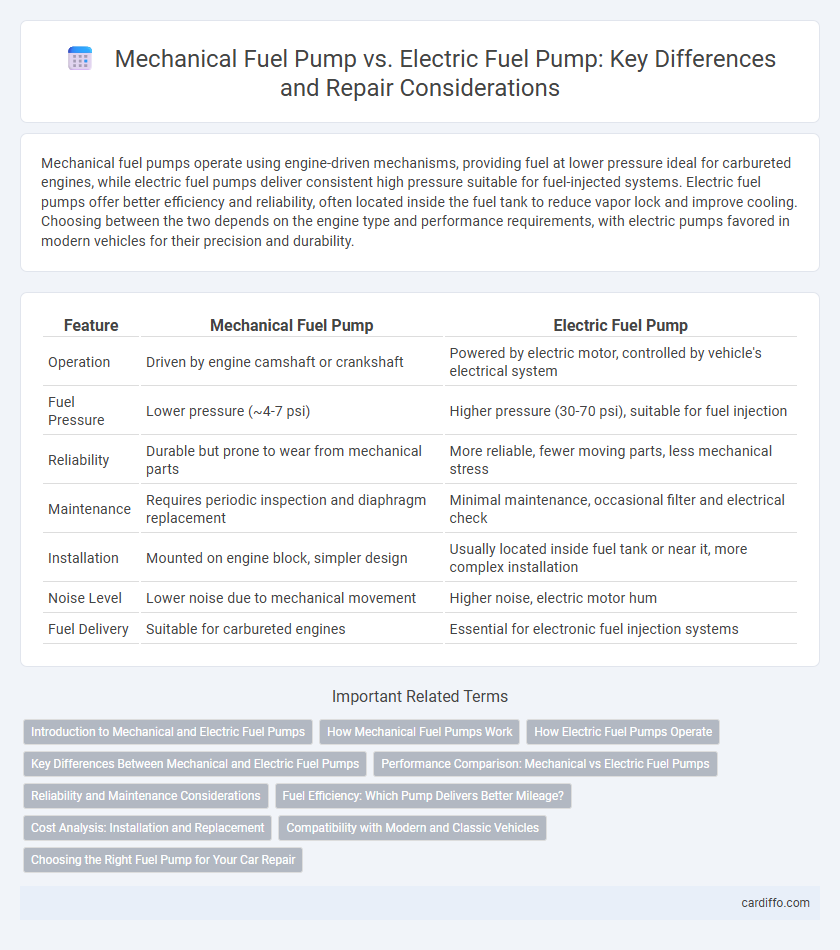

Table of Comparison

| Feature | Mechanical Fuel Pump | Electric Fuel Pump |

|---|---|---|

| Operation | Driven by engine camshaft or crankshaft | Powered by electric motor, controlled by vehicle's electrical system |

| Fuel Pressure | Lower pressure (~4-7 psi) | Higher pressure (30-70 psi), suitable for fuel injection |

| Reliability | Durable but prone to wear from mechanical parts | More reliable, fewer moving parts, less mechanical stress |

| Maintenance | Requires periodic inspection and diaphragm replacement | Minimal maintenance, occasional filter and electrical check |

| Installation | Mounted on engine block, simpler design | Usually located inside fuel tank or near it, more complex installation |

| Noise Level | Lower noise due to mechanical movement | Higher noise, electric motor hum |

| Fuel Delivery | Suitable for carbureted engines | Essential for electronic fuel injection systems |

Introduction to Mechanical and Electric Fuel Pumps

Mechanical fuel pumps operate using engine-driven cams or pushrods to move fuel from the tank to the carburetor or fuel injectors, providing reliable fuel delivery without electrical power. Electric fuel pumps rely on an electrically powered motor to generate fuel pressure, offering consistent and precise fuel flow ideal for modern fuel injection systems. Both types of pumps are critical in vehicle fuel systems, but electric pumps provide greater efficiency and are standard in newer models.

How Mechanical Fuel Pumps Work

Mechanical fuel pumps operate by using engine-driven components, such as a camshaft or crankshaft, to create suction that draws fuel from the tank through a diaphragm or piston mechanism. These pumps deliver fuel at low pressure, typically between 4 to 10 psi, directly to the carburetor or fuel injection system without requiring external power sources. Their reliability depends on precise mechanical movement and they are commonly found in older vehicles with carbureted engines.

How Electric Fuel Pumps Operate

Electric fuel pumps operate by using an electric motor to drive an internal rotor or gear that pressurizes fuel and delivers it through the fuel lines to the engine. These pumps are typically located inside the fuel tank, allowing them to push fuel efficiently and maintain consistent pressure for optimal engine performance. Because they are electrically powered, electric fuel pumps provide precise fuel flow control and can respond to varying engine demands more quickly than mechanical fuel pumps.

Key Differences Between Mechanical and Electric Fuel Pumps

Mechanical fuel pumps operate using engine-driven cams to create pressure and move fuel, typically found in older carbureted vehicles, while electric fuel pumps rely on an electric motor to supply consistent fuel flow, commonly used in modern fuel-injected systems. Mechanical pumps are generally less precise and produce lower fuel pressure compared to electric pumps, which deliver higher pressure for efficient fuel atomization and improved engine performance. Electric pumps offer better control and reliability, often integrated with fuel management systems, whereas mechanical pumps have simpler designs and depend entirely on engine RPM.

Performance Comparison: Mechanical vs Electric Fuel Pumps

Mechanical fuel pumps rely on engine-driven cams to deliver fuel at lower pressures, providing reliable performance in carbureted systems but limited efficiency at higher speeds. Electric fuel pumps offer consistent, high-pressure fuel delivery necessary for modern fuel injection systems, enhancing engine performance and fuel efficiency. Electric pumps also allow for precise fuel flow control, reducing emissions and improving overall drivability compared to mechanical pumps.

Reliability and Maintenance Considerations

Mechanical fuel pumps generally offer greater reliability in older vehicles due to their simple design and fewer electronic components, resulting in lower failure rates under normal operating conditions. Electric fuel pumps, while more complex, provide consistent fuel pressure and are easier to replace but require regular maintenance checks for wiring and fuel filter integrity to prevent malfunctions. Maintenance for mechanical pumps mainly involves inspecting the diaphragm and valves, whereas electric pumps demand more attention to electrical connections and potential overheating issues.

Fuel Efficiency: Which Pump Delivers Better Mileage?

Mechanical fuel pumps typically offer lower fuel efficiency due to their reliance on engine-driven operation, which can cause inconsistent fuel pressure and flow. Electric fuel pumps provide more precise fuel delivery by maintaining constant pressure, resulting in improved combustion efficiency and better mileage. Vehicles equipped with electric fuel pumps often experience enhanced fuel economy, especially under varying engine loads and speeds.

Cost Analysis: Installation and Replacement

Mechanical fuel pumps generally incur lower installation and replacement costs due to their simpler design and compatibility with older vehicles, making them more cost-effective for basic fuel delivery systems. Electric fuel pumps, while more expensive initially, often demand higher labor costs for installation and replacement because of their complex wiring and integration with modern electronic control units. Long-term expenses favor electric pumps through improved fuel efficiency and fewer mechanical failures, offsetting their upfront cost differences in repair and maintenance.

Compatibility with Modern and Classic Vehicles

Mechanical fuel pumps are typically compatible with classic vehicles due to their simple design and reliance on engine movement to operate, making them ideal for older carbureted engines. Electric fuel pumps suit modern vehicles equipped with electronic fuel injection systems, providing consistent fuel pressure and improved efficiency. Choosing a fuel pump depends on vehicle make, model, and fuel system type, ensuring optimal engine performance and reliability.

Choosing the Right Fuel Pump for Your Car Repair

Mechanical fuel pumps utilize engine-driven mechanisms for fuel delivery, offering reliability in older car models with simpler fuel systems, while electric fuel pumps provide consistent pressure and efficiency suited for modern vehicles with advanced fuel injection. Selecting the right fuel pump for car repair depends on the vehicle's make, age, fuel system type, and performance requirements, emphasizing compatibility with OEM specifications to ensure optimal engine performance. Electric fuel pumps often require careful wiring and fuel line inspection, whereas mechanical pumps necessitate attention to gasket integrity and diaphragm condition during replacement.

Mechanical fuel pump vs Electric fuel pump Infographic

cardiffo.com

cardiffo.com