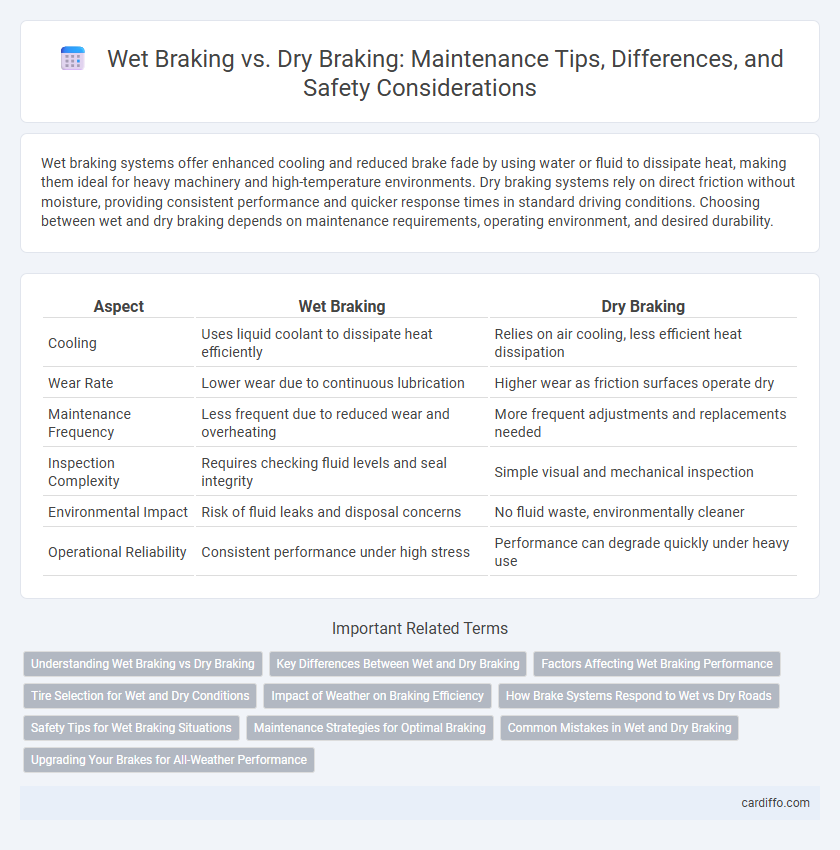

Wet braking systems offer enhanced cooling and reduced brake fade by using water or fluid to dissipate heat, making them ideal for heavy machinery and high-temperature environments. Dry braking systems rely on direct friction without moisture, providing consistent performance and quicker response times in standard driving conditions. Choosing between wet and dry braking depends on maintenance requirements, operating environment, and desired durability.

Table of Comparison

| Aspect | Wet Braking | Dry Braking |

|---|---|---|

| Cooling | Uses liquid coolant to dissipate heat efficiently | Relies on air cooling, less efficient heat dissipation |

| Wear Rate | Lower wear due to continuous lubrication | Higher wear as friction surfaces operate dry |

| Maintenance Frequency | Less frequent due to reduced wear and overheating | More frequent adjustments and replacements needed |

| Inspection Complexity | Requires checking fluid levels and seal integrity | Simple visual and mechanical inspection |

| Environmental Impact | Risk of fluid leaks and disposal concerns | No fluid waste, environmentally cleaner |

| Operational Reliability | Consistent performance under high stress | Performance can degrade quickly under heavy use |

Understanding Wet Braking vs Dry Braking

Wet braking occurs when brake components are exposed to water or moisture, significantly reducing friction and braking efficiency due to a lubricating film on the rotor or drum surface. Dry braking involves brake systems operating in normal, dry conditions, providing consistent friction and optimal stopping power without interference from external moisture. Understanding the differences between wet and dry braking is crucial for maintaining braking performance and ensuring safety in varied environmental conditions.

Key Differences Between Wet and Dry Braking

Wet braking systems use brake pads and rotors that operate in a lubricated environment, reducing friction and heat buildup, which extends component lifespan but may cause longer stopping distances. Dry braking relies on direct contact between brake pads and rotors without lubrication, providing more immediate stopping power and consistent brake feel but increasing wear and heat generation. Key differences include performance in various weather conditions, maintenance frequency, and durability, with wet brakes excelling in corrosion resistance and dry brakes offering sharper response times.

Factors Affecting Wet Braking Performance

Wet braking performance is significantly influenced by factors such as water film thickness on brake surfaces, brake pad material composition, and rotor design, which affect friction levels and heat dissipation. Contaminants like oil and debris exacerbate wet conditions by reducing contact friction and increasing stopping distances. Proper maintenance, including regular inspection and replacement of worn pads and rotors, is essential to optimize wet braking efficiency and ensure vehicle safety.

Tire Selection for Wet and Dry Conditions

Tire selection significantly impacts braking performance, with wet braking requiring tires that have deeper treads and specialized rubber compounds to channel water and maintain grip on slippery surfaces. Dry braking benefits from tires with harder compounds and optimized tread patterns that maximize contact area and heat dissipation for improved stopping power. Choosing the correct tire type for prevailing weather conditions enhances safety, reduces stopping distances, and minimizes wear during braking.

Impact of Weather on Braking Efficiency

Wet braking significantly reduces friction between brake pads and rotors, leading to longer stopping distances and decreased braking efficiency compared to dry braking conditions. Moisture causes a thin water film that prevents optimal contact, increasing wear and the potential for brake fade in wet weather. Regular maintenance such as pad inspection and rotor resurfacing is crucial to ensure reliable braking performance under varying weather conditions.

How Brake Systems Respond to Wet vs Dry Roads

Brake systems respond differently to wet and dry road conditions due to variations in friction between brake components and the road surface. In wet braking, water reduces the friction coefficient, causing longer stopping distances and requiring brake pads to work harder to maintain effective deceleration. Dry braking offers optimal friction levels, allowing brake systems to achieve maximum grip and shorter stopping distances, enhancing overall vehicle control and safety.

Safety Tips for Wet Braking Situations

In wet braking situations, maintaining a safe following distance and reducing speed are critical to prevent hydroplaning and ensure effective stopping power. Regularly inspect brake pads and rotors for wear and ensure tires have adequate tread depth to maximize grip on slippery surfaces. Avoid sudden or hard braking by applying gradual pressure to the brake pedal, allowing the vehicle to slow smoothly and maintain better control.

Maintenance Strategies for Optimal Braking

Wet braking systems require regular inspection of fluid levels and seals to prevent leaks and maintain hydraulic pressure, while dry braking systems demand frequent pad and rotor checks to avoid excessive wear and overheating. Incorporating predictive maintenance tools such as thermal sensors and vibration analysis helps identify early signs of component degradation, optimizing service intervals. Implementing tailored lubrication schedules for wet brakes and ensuring debris-free environments for dry brakes significantly enhance overall braking performance and lifespan.

Common Mistakes in Wet and Dry Braking

Common mistakes in wet braking include excessive braking force that leads to hydroplaning and reduced tire-road traction, causing longer stopping distances. In dry braking, typical errors involve abrupt braking, which results in uneven tire wear and potential brake system overheating. Regular maintenance checks and smooth braking techniques optimize safety and prolong brake component lifespan.

Upgrading Your Brakes for All-Weather Performance

Upgrading to wet braking systems enhances performance in rainy or humid conditions by maintaining effective stopping power through water-resistant components and improved heat dissipation. Dry braking systems, while efficient in dry conditions, often suffer reduced friction and increased wear when exposed to moisture, leading to compromised safety. Selecting all-weather brake upgrades, such as ceramic or composite pads with enhanced water-shedding designs, ensures consistent braking efficiency and longer maintenance intervals.

Wet Braking vs Dry Braking Infographic

cardiffo.com

cardiffo.com