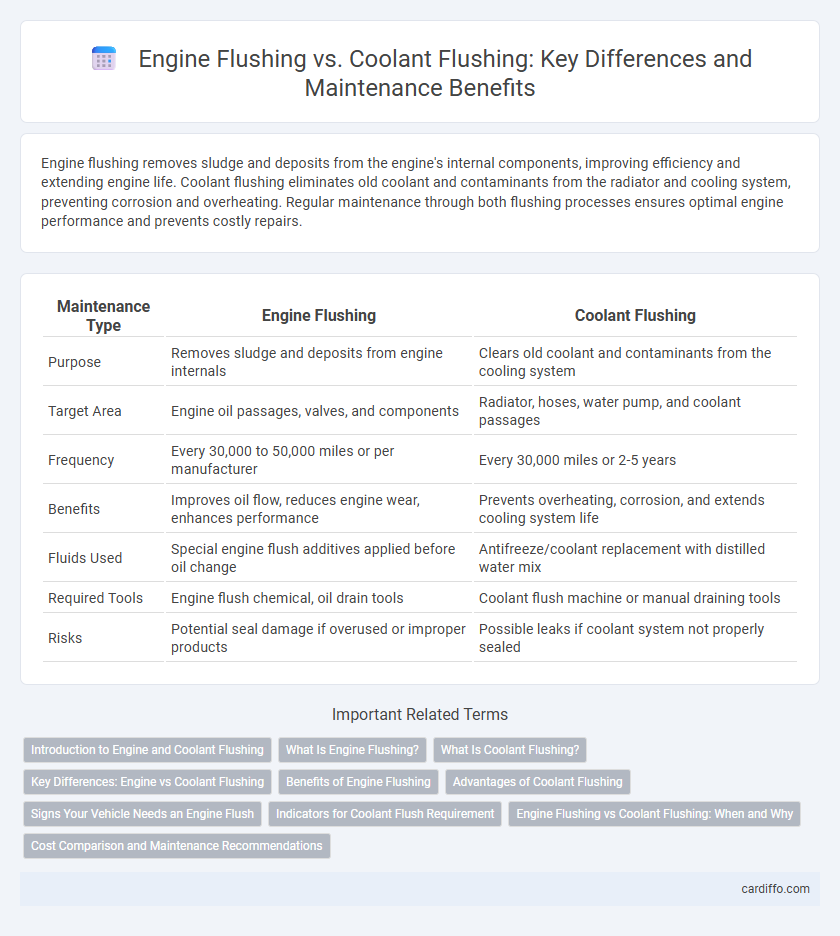

Engine flushing removes sludge and deposits from the engine's internal components, improving efficiency and extending engine life. Coolant flushing eliminates old coolant and contaminants from the radiator and cooling system, preventing corrosion and overheating. Regular maintenance through both flushing processes ensures optimal engine performance and prevents costly repairs.

Table of Comparison

| Maintenance Type | Engine Flushing | Coolant Flushing |

|---|---|---|

| Purpose | Removes sludge and deposits from engine internals | Clears old coolant and contaminants from the cooling system |

| Target Area | Engine oil passages, valves, and components | Radiator, hoses, water pump, and coolant passages |

| Frequency | Every 30,000 to 50,000 miles or per manufacturer | Every 30,000 miles or 2-5 years |

| Benefits | Improves oil flow, reduces engine wear, enhances performance | Prevents overheating, corrosion, and extends cooling system life |

| Fluids Used | Special engine flush additives applied before oil change | Antifreeze/coolant replacement with distilled water mix |

| Required Tools | Engine flush chemical, oil drain tools | Coolant flush machine or manual draining tools |

| Risks | Potential seal damage if overused or improper products | Possible leaks if coolant system not properly sealed |

Introduction to Engine and Coolant Flushing

Engine flushing removes sludge, deposits, and contaminants from the engine oil passages to improve lubrication and engine performance. Coolant flushing involves draining and replacing the antifreeze and coolant mixture to prevent overheating and corrosion within the cooling system. Both maintenance procedures enhance engine longevity and efficiency by addressing different internal systems.

What Is Engine Flushing?

Engine flushing is a maintenance procedure that involves circulating a specialized cleaning solution through the engine to dissolve sludge, varnish, and contaminants buildup. This process helps restore proper engine lubrication by removing deposits that can impede oil flow and reduce efficiency. Unlike coolant flushing, which targets the cooling system, engine flushing specifically improves internal engine cleanliness and performance.

What Is Coolant Flushing?

Coolant flushing involves thoroughly draining and replacing the old antifreeze and contaminants from a vehicle's cooling system to prevent overheating and corrosion. This process helps maintain optimal engine temperature by ensuring the coolant mixture remains effective in heat transfer and anti-corrosion protection. Regular coolant flushing extends radiator and engine lifespan by removing rust, scale, and debris buildup that can clog passages and reduce cooling efficiency.

Key Differences: Engine vs Coolant Flushing

Engine flushing involves cleaning internal engine components by circulating a chemical solution to remove sludge, deposits, and contaminants, improving engine performance and longevity. Coolant flushing, on the other hand, focuses on flushing out the radiator and cooling system to eliminate rust, corrosion, and old antifreeze, ensuring optimal temperature regulation and preventing overheating. The key difference lies in their target areas: engine flushing cleans oil-related deposits inside the engine, while coolant flushing addresses the cooling system's fluid and components.

Benefits of Engine Flushing

Engine flushing removes accumulated sludge, deposits, and contaminants from internal engine components, improving overall engine performance and fuel efficiency. It helps prevent overheating and extends engine life by restoring optimal lubrication and heat dissipation. Compared to coolant flushing, engine flushing directly cleans the engine oil passages, protecting critical parts like pistons, valves, and bearings from wear and damage.

Advantages of Coolant Flushing

Coolant flushing improves engine cooling system efficiency by removing rust, scale, and contaminants that degrade performance. It extends the lifespan of the radiator, water pump, and thermostat by preventing corrosion and buildup, reducing the risk of overheating. Regular coolant flushing also maintains optimal engine temperature, enhancing fuel efficiency and preventing costly repairs caused by coolant system failure.

Signs Your Vehicle Needs an Engine Flush

Engine flushing becomes necessary when you notice symptoms like reduced engine performance, excessive oil sludge buildup, or unusual knocking sounds indicating clogged internal passages. Dark, dirty oil and increased engine temperature can also signal the need for an engine flush to remove contaminants and restore proper lubrication. Unlike coolant flushing, which addresses overheating and corrosion in the cooling system, engine flushing targets the cleaning of critical engine components to prevent wear and extend engine life.

Indicators for Coolant Flush Requirement

Coolant flush is required when indicators such as rusty or discolored coolant, overheating engine temperature, or a sweet smell from the radiator emerge, signaling contamination or degradation of the cooling system. Frequent coolant flushing prevents corrosion, sediment buildup, and maintains optimal engine temperature regulation, ensuring efficient performance. Monitoring coolant color and consistency alongside engine temperature warnings helps determine precise timing for a necessary coolant flush.

Engine Flushing vs Coolant Flushing: When and Why

Engine flushing involves cleaning the internal components of the engine by circulating a chemical solvent to remove sludge and deposits, improving engine performance and longevity. Coolant flushing replaces old antifreeze and removes rust, scale, and contaminants from the cooling system to prevent overheating and corrosion. Engine flushing is typically performed during significant maintenance intervals or when sludge buildup affects engine operation, while coolant flushing is recommended every 2-5 years or as specified by the vehicle manufacturer to ensure optimal cooling system function.

Cost Comparison and Maintenance Recommendations

Engine flushing generally costs between $50 and $150, while coolant flushing ranges from $100 to $150, making engine flushing a more affordable maintenance option. Regular engine flushing helps remove sludge and contaminants, improving performance and fuel efficiency, whereas coolant flushing prevents overheating and corrosion by replacing old coolant. For optimal engine longevity, follow manufacturer guidelines--engine flushing annually or every 30,000 miles and coolant flushing every 2-3 years or 30,000 to 50,000 miles.

Engine Flushing vs Coolant Flushing Infographic

cardiffo.com

cardiffo.com