Drum brake maintenance involves regular inspection for worn brake shoes and adjustment of the shoe clearance to ensure optimal performance. Disc brake maintenance typically requires monitoring brake pad thickness and rotor condition, along with frequent cleaning to prevent dust buildup and noise. Understanding the distinct maintenance needs of each brake type helps maximize braking efficiency and vehicle safety.

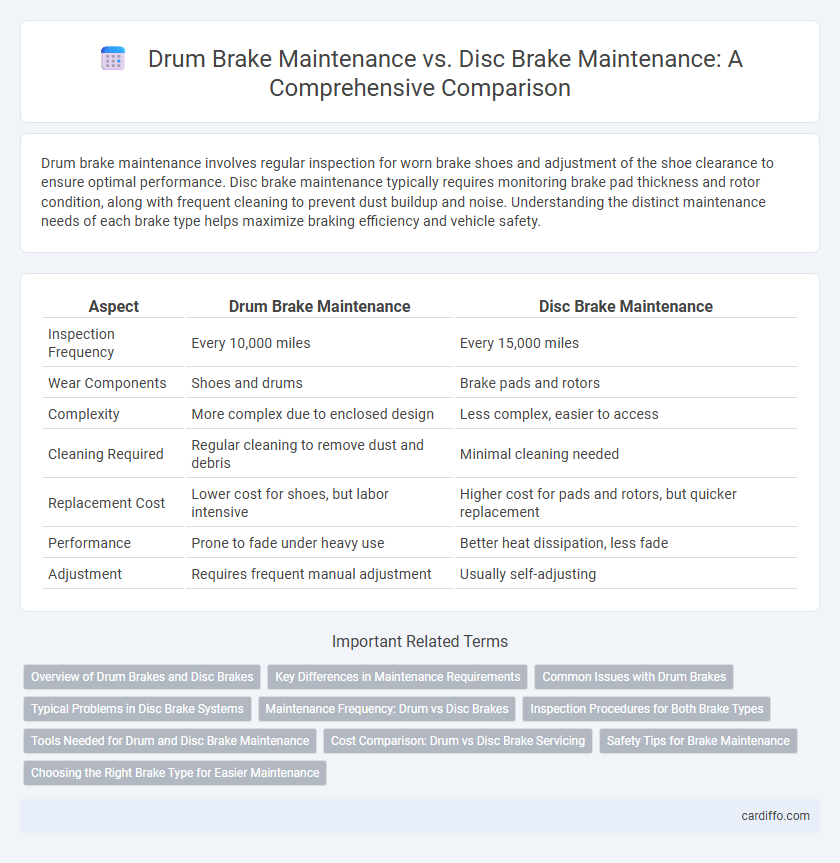

Table of Comparison

| Aspect | Drum Brake Maintenance | Disc Brake Maintenance |

|---|---|---|

| Inspection Frequency | Every 10,000 miles | Every 15,000 miles |

| Wear Components | Shoes and drums | Brake pads and rotors |

| Complexity | More complex due to enclosed design | Less complex, easier to access |

| Cleaning Required | Regular cleaning to remove dust and debris | Minimal cleaning needed |

| Replacement Cost | Lower cost for shoes, but labor intensive | Higher cost for pads and rotors, but quicker replacement |

| Performance | Prone to fade under heavy use | Better heat dissipation, less fade |

| Adjustment | Requires frequent manual adjustment | Usually self-adjusting |

Overview of Drum Brakes and Disc Brakes

Drum brakes feature brake shoes that press outward against a rotating drum to create friction, often requiring adjustment due to shoe wear and drum surface conditions. Disc brakes utilize calipers to squeeze brake pads against a spinning disc, allowing for better heat dissipation and generally easier inspection and pad replacement. Maintenance of drum brakes typically involves shoe replacement and drum resurfacing, while disc brake maintenance focuses on pad wear and rotor condition checks.

Key Differences in Maintenance Requirements

Drum brake maintenance typically involves inspecting and replacing brake shoes, adjusting the self-energizing mechanism, and cleaning accumulated dust inside the drum, which can be time-consuming compared to disc brakes. Disc brake maintenance centers on inspecting brake pads, measuring rotor thickness, and ensuring caliper functionality, often requiring less frequent adjustments due to the self-adjusting nature of the system. Key differences include drum brakes needing regular manual adjustments and cleaning, whereas disc brakes primarily demand pad replacement and rotor inspection for optimal performance.

Common Issues with Drum Brakes

Drum brake maintenance often involves addressing common issues such as brake shoe wear, wheel cylinder leaks, and drum surface scoring, which can reduce braking efficiency and cause noise. Regular inspection and timely replacement of brake shoes and wheel cylinders help prevent these problems and ensure optimal performance. Unlike disc brakes, drum brakes are more prone to overheating and brake fade due to their enclosed design, making routine maintenance essential for safety and durability.

Typical Problems in Disc Brake Systems

Typical problems in disc brake systems include brake pad wear, rotor warping, and caliper malfunction, which can lead to reduced braking efficiency and increased stopping distances. Contaminated brake fluid and corrosion may also cause sticking calipers or uneven braking pressure. Timely inspection and replacement of brake pads, rotors, and fluid are essential to maintain optimal disc brake performance.

Maintenance Frequency: Drum vs Disc Brakes

Drum brakes generally require less frequent maintenance than disc brakes due to their enclosed design, which protects internal components from dirt and debris. Disc brakes, exposed to the elements, often need more regular inspection and pad replacement to ensure optimal performance and safety. Maintenance schedules for drum brakes can extend to every 30,000 miles, while disc brakes typically benefit from checks every 20,000 miles or sooner in high-demand conditions.

Inspection Procedures for Both Brake Types

Inspection procedures for drum brakes involve checking the brake shoes for wear, springs for tension, and the drum surface for scoring or cracks, ensuring proper adjustment of the self-energizing mechanism. Disc brake inspections require examining the brake pads for thickness, rotor surfaces for warping or grooves, and caliper functionality, emphasizing hydraulic fluid levels and potential leaks. Regular inspection of both types includes measuring component thickness against manufacturer specifications to maintain optimal braking performance and safety.

Tools Needed for Drum and Disc Brake Maintenance

Effective drum brake maintenance requires tools such as brake spring pliers, a brake adjusting spoon, and a brake drum puller to handle the complex springs and components. Disc brake maintenance commonly involves a C-clamp or brake caliper tool for piston retraction, a torque wrench for proper bolt tightening, and brake pad spreaders to ensure even pad installation. Both types benefit from quality brake cleaner and a lug wrench to facilitate safe and efficient service.

Cost Comparison: Drum vs Disc Brake Servicing

Drum brake maintenance generally incurs lower initial servicing costs due to simpler components and less frequent adjustments, while disc brake maintenance, though often more expensive upfront, benefits from easier inspections and replacement of brake pads. Over time, disc brakes may reduce overall expenses because of better heat dissipation and longer-lasting, wear-resistant materials. Comparing cost-effectiveness depends on vehicle usage patterns, with drum brakes favored for budget-conscious owners and disc brakes preferred for performance and durability.

Safety Tips for Brake Maintenance

Regular inspection of drum brakes involves checking the brake shoes and wheel cylinders for wear or leaks, while disc brake maintenance requires monitoring the brake pads and rotors for thinning or warping. Always ensure brake fluid levels are topped up and free of contaminants to maintain hydraulic efficiency across both brake types. Use proper tools and follow manufacturer torque specifications to avoid compromising brake performance and ensure maximum safety.

Choosing the Right Brake Type for Easier Maintenance

Drum brake maintenance typically involves cleaning and adjusting the brake shoes, which can be more labor-intensive due to the enclosed design and risk of dust accumulation. Disc brakes offer easier maintenance with straightforward pad replacement and self-adjusting calipers, reducing the frequency of manual adjustments. Choosing disc brakes enhances convenience and efficiency in maintenance, making them ideal for vehicles requiring frequent servicing or high performance.

Drum Brake Maintenance vs Disc Brake Maintenance Infographic

cardiffo.com

cardiffo.com