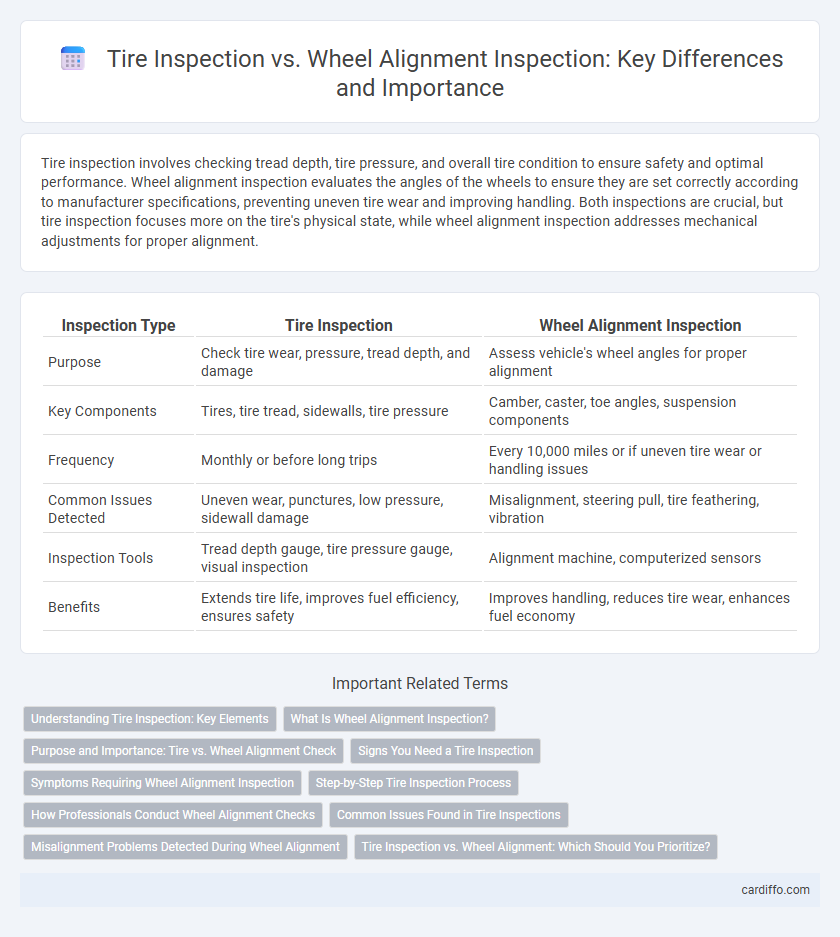

Tire inspection involves checking tread depth, tire pressure, and overall tire condition to ensure safety and optimal performance. Wheel alignment inspection evaluates the angles of the wheels to ensure they are set correctly according to manufacturer specifications, preventing uneven tire wear and improving handling. Both inspections are crucial, but tire inspection focuses more on the tire's physical state, while wheel alignment inspection addresses mechanical adjustments for proper alignment.

Table of Comparison

| Inspection Type | Tire Inspection | Wheel Alignment Inspection |

|---|---|---|

| Purpose | Check tire wear, pressure, tread depth, and damage | Assess vehicle's wheel angles for proper alignment |

| Key Components | Tires, tire tread, sidewalls, tire pressure | Camber, caster, toe angles, suspension components |

| Frequency | Monthly or before long trips | Every 10,000 miles or if uneven tire wear or handling issues |

| Common Issues Detected | Uneven wear, punctures, low pressure, sidewall damage | Misalignment, steering pull, tire feathering, vibration |

| Inspection Tools | Tread depth gauge, tire pressure gauge, visual inspection | Alignment machine, computerized sensors |

| Benefits | Extends tire life, improves fuel efficiency, ensures safety | Improves handling, reduces tire wear, enhances fuel economy |

Understanding Tire Inspection: Key Elements

Tire inspection focuses on evaluating tread depth, wear patterns, and tire pressure to ensure optimal safety and performance. Key elements include checking for visible damage such as cuts, punctures, and sidewall bulges, as well as monitoring even tread wear to prevent premature tire replacement. Accurate tire inspection helps identify issues that affect vehicle handling and fuel efficiency before proceeding to wheel alignment inspection.

What Is Wheel Alignment Inspection?

Wheel alignment inspection evaluates the angles of the wheels to ensure they meet manufacturer specifications, optimizing vehicle handling and tire longevity. This process checks camber, caster, and toe angles using specialized alignment machines to detect misalignments caused by road conditions or collisions. Proper wheel alignment inspection prevents uneven tire wear, improves fuel efficiency, and enhances driving safety.

Purpose and Importance: Tire vs. Wheel Alignment Check

Tire inspection focuses on assessing tread depth, wear patterns, and pressure to ensure safety, optimal traction, and fuel efficiency. Wheel alignment inspection evaluates the angles of wheels to prevent uneven tire wear, improve handling, and extend tire life. Both checks are critical for vehicle stability and safety but target different aspects of tire performance and vehicle operation.

Signs You Need a Tire Inspection

Uneven tire wear, such as bald spots or cupping, often signals the need for a tire inspection to prevent safety hazards. Vibrations or pulling sensations while driving indicate potential tire issues requiring immediate evaluation. Regular tire inspections detect damage like sidewall bulges, tread separation, or embedded objects, ensuring optimal traction and vehicle stability.

Symptoms Requiring Wheel Alignment Inspection

Uneven tire wear, a common symptom requiring wheel alignment inspection, indicates misaligned wheels causing improper contact with the road surface. Steering wheel vibration and the vehicle pulling to one side while driving also signal alignment issues that tire inspection alone cannot detect. Addressing wheel alignment after identifying these symptoms enhances tire performance and extends tire lifespan.

Step-by-Step Tire Inspection Process

Step-by-step tire inspection begins with checking tread depth using a tread depth gauge to ensure it meets safety standards above 2/32 inch. Visual examination follows, identifying cuts, cracks, bulges, or uneven wear patterns that indicate alignment or suspension issues. Finally, measuring tire pressure with a reliable gauge confirms optimal inflation, enhancing vehicle performance and tire lifespan.

How Professionals Conduct Wheel Alignment Checks

Professionals conduct wheel alignment inspections using advanced alignment machines that measure the angles of the wheels relative to the vehicle's specifications, including camber, caster, and toe angles. Unlike tire inspections, which focus on tread depth and wear patterns, wheel alignment checks ensure optimal handling, tire longevity, and fuel efficiency by adjusting the wheels to manufacturer-recommended settings. Precision sensors and computerized systems provide real-time data, allowing technicians to correct misalignments accurately.

Common Issues Found in Tire Inspections

Tire inspections commonly reveal issues such as uneven tread wear, cuts, bulges, and embedded objects that compromise safety and performance. These problems often result from improper inflation, misalignment, or road hazards, necessitating timely intervention to prevent blowouts or reduced traction. Unlike wheel alignment inspections that focus on adjusting angles for optimal driving dynamics, tire inspections prioritize identifying physical damage and wear patterns critical for maintaining tire integrity.

Misalignment Problems Detected During Wheel Alignment

Wheel alignment inspections primarily detect misalignment problems such as uneven tire wear, steering wheel off-center, and vehicle pulling to one side, which are not typically identified during standard tire inspections. Misalignment can cause premature tire degradation and unsafe handling conditions, emphasizing the importance of regular alignment checks to maintain vehicle stability and extend tire life. Detecting and correcting alignment issues early prevents costly repairs and improves overall driving safety.

Tire Inspection vs. Wheel Alignment: Which Should You Prioritize?

Tire inspection evaluates tread depth, pressure, and overall wear to ensure safety and extend tire life, while wheel alignment inspection focuses on correcting angles to prevent uneven tire wear and improve vehicle handling. Prioritizing tire inspection helps detect immediate safety hazards like punctures or excessive wear, whereas wheel alignment inspection supports long-term tire performance and fuel efficiency. For optimal vehicle maintenance, regular tire inspections combined with periodic wheel alignment checks provide the best balance of safety, tire longevity, and driving comfort.

Tire inspection vs wheel alignment inspection Infographic

cardiffo.com

cardiffo.com