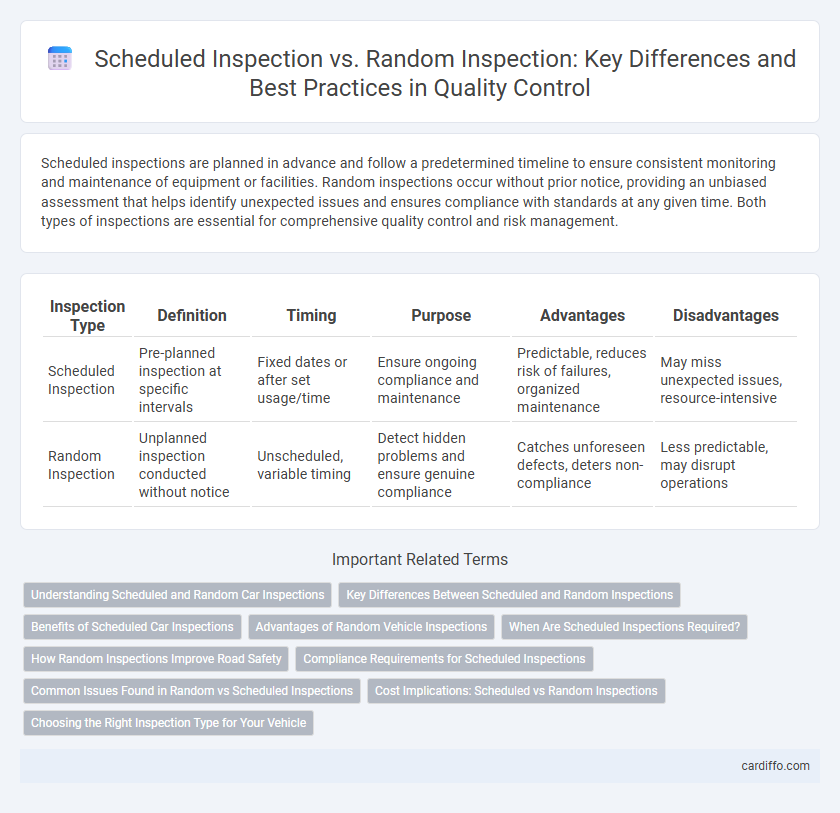

Scheduled inspections are planned in advance and follow a predetermined timeline to ensure consistent monitoring and maintenance of equipment or facilities. Random inspections occur without prior notice, providing an unbiased assessment that helps identify unexpected issues and ensures compliance with standards at any given time. Both types of inspections are essential for comprehensive quality control and risk management.

Table of Comparison

| Inspection Type | Definition | Timing | Purpose | Advantages | Disadvantages |

|---|---|---|---|---|---|

| Scheduled Inspection | Pre-planned inspection at specific intervals | Fixed dates or after set usage/time | Ensure ongoing compliance and maintenance | Predictable, reduces risk of failures, organized maintenance | May miss unexpected issues, resource-intensive |

| Random Inspection | Unplanned inspection conducted without notice | Unscheduled, variable timing | Detect hidden problems and ensure genuine compliance | Catches unforeseen defects, deters non-compliance | Less predictable, may disrupt operations |

Understanding Scheduled and Random Car Inspections

Scheduled inspections follow a predetermined timeline, ensuring vehicles meet safety and emission standards at regular intervals. Random inspections occur unpredictably, targeting vehicles based on risk factors or for compliance checks without prior notice. Both methods complement each other by maintaining regulatory compliance and enhancing road safety through systematic and spontaneous vehicle evaluations.

Key Differences Between Scheduled and Random Inspections

Scheduled inspections are planned in advance with a fixed timetable, allowing thorough preparation and documentation review to ensure compliance with safety and quality standards. Random inspections occur unexpectedly, aiming to capture real-time conditions and identify ongoing issues without prior notice, enhancing the reliability of compliance assessment. The key differences lie in predictability, scope of preparation, and the ability to detect unreported or intermittent non-compliance.

Benefits of Scheduled Car Inspections

Scheduled car inspections ensure consistent vehicle safety and compliance with regulations by adhering to manufacturer-recommended intervals. Regular inspections help identify potential issues early, reducing the risk of costly repairs and enhancing overall vehicle reliability. Predictable inspection timelines also facilitate better maintenance planning and record-keeping for both drivers and service providers.

Advantages of Random Vehicle Inspections

Random vehicle inspections enhance regulatory compliance by deterring violations due to unpredictability, increasing overall safety standards on the roads. They enable authorities to identify hidden defects and illegal modifications that scheduled inspections might miss, ensuring vehicles meet environmental and safety regulations continuously. This inspection method also promotes fairness by preventing manipulation of inspection timing, leading to more accurate assessments of vehicle conditions.

When Are Scheduled Inspections Required?

Scheduled inspections are required when regulatory standards mandate regular safety checks to ensure compliance with industry-specific laws and operational protocols. These inspections often occur at predetermined intervals based on equipment usage, risk assessment, or legal requirements as specified by bodies such as OSHA or the EPA. Companies implement scheduled inspections to proactively identify potential hazards and maintain certification and insurance conditions.

How Random Inspections Improve Road Safety

Random inspections enhance road safety by introducing unpredictability, which deters non-compliance among drivers and vehicle operators more effectively than scheduled checks. These inspections enable authorities to identify high-risk behaviors and vehicle defects that might be missed during predictable, scheduled inspections. By increasing the perceived risk of being caught, random inspections contribute to consistent adherence to traffic regulations and maintenance standards, reducing accidents and improving overall road safety.

Compliance Requirements for Scheduled Inspections

Scheduled inspections must strictly adhere to compliance requirements set by industry regulations and safety standards, ensuring systematic evaluation at predetermined intervals. These inspections facilitate thorough documentation and accountability, supporting regulatory audits and risk management strategies. Compliance mandates often specify precise timing, scope, and reporting protocols that scheduled inspections are designed to meet effectively.

Common Issues Found in Random vs Scheduled Inspections

Random inspections frequently uncover unreported safety violations, equipment malfunctions, and non-compliance with operational protocols that scheduled inspections might overlook due to prior preparation. Scheduled inspections typically identify issues related to routine maintenance lapses and documentation errors but can miss spontaneous or concealed hazards. Data indicates that random inspections lead to a higher detection rate of critical safety risks, highlighting their importance in comprehensive safety management programs.

Cost Implications: Scheduled vs Random Inspections

Scheduled inspections allow for better budget allocation by predicting inspection costs and minimizing unexpected expenses, leading to cost efficiency in maintenance planning. Random inspections often incur higher operational costs due to the need for rapid mobilization of resources and potential disruption to normal workflows. Businesses can reduce overall inspection costs by optimizing the balance between scheduled and random inspections, ensuring compliance while controlling expenses.

Choosing the Right Inspection Type for Your Vehicle

Scheduled inspection ensures regular, timely evaluation of your vehicle's essential systems, helping to maintain optimal performance and compliance with safety regulations. Random inspection can detect unexpected issues or non-compliance by evaluating the vehicle at unpredictable intervals, offering an added layer of security. Choosing the right inspection type depends on your vehicle's usage patterns, risk factors, and regulatory requirements to ensure both safety and efficiency.

Scheduled inspection vs random inspection Infographic

cardiffo.com

cardiffo.com