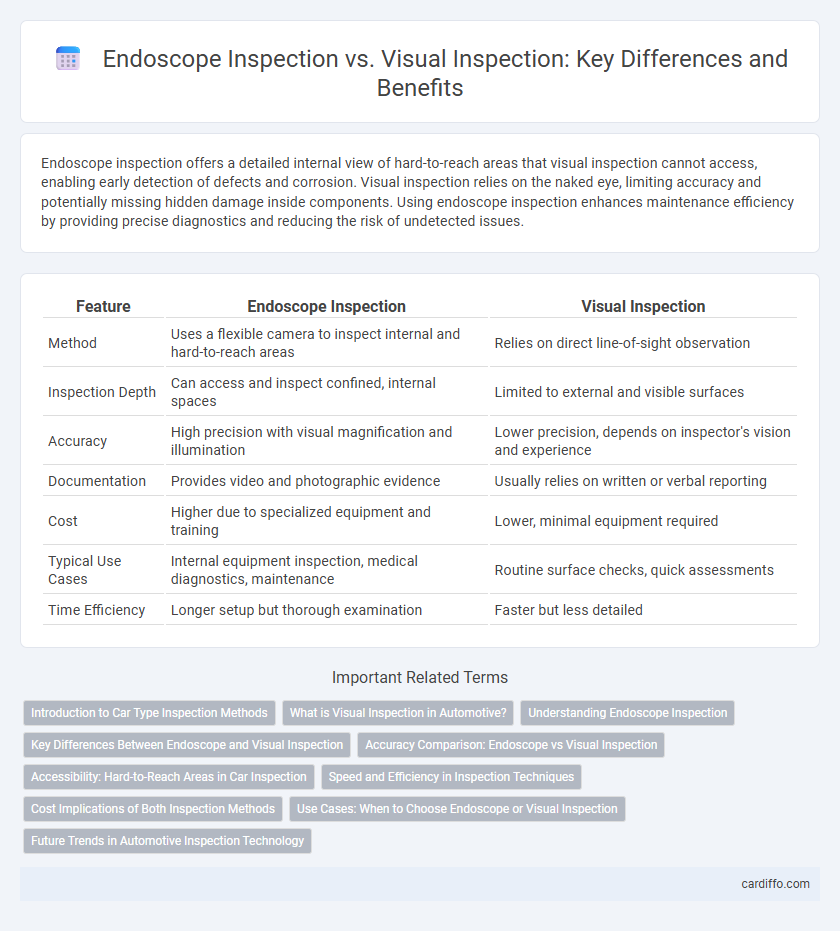

Endoscope inspection offers a detailed internal view of hard-to-reach areas that visual inspection cannot access, enabling early detection of defects and corrosion. Visual inspection relies on the naked eye, limiting accuracy and potentially missing hidden damage inside components. Using endoscope inspection enhances maintenance efficiency by providing precise diagnostics and reducing the risk of undetected issues.

Table of Comparison

| Feature | Endoscope Inspection | Visual Inspection |

|---|---|---|

| Method | Uses a flexible camera to inspect internal and hard-to-reach areas | Relies on direct line-of-sight observation |

| Inspection Depth | Can access and inspect confined, internal spaces | Limited to external and visible surfaces |

| Accuracy | High precision with visual magnification and illumination | Lower precision, depends on inspector's vision and experience |

| Documentation | Provides video and photographic evidence | Usually relies on written or verbal reporting |

| Cost | Higher due to specialized equipment and training | Lower, minimal equipment required |

| Typical Use Cases | Internal equipment inspection, medical diagnostics, maintenance | Routine surface checks, quick assessments |

| Time Efficiency | Longer setup but thorough examination | Faster but less detailed |

Introduction to Car Type Inspection Methods

Endoscope inspection enables detailed internal examination of car components, revealing defects invisible to traditional visual inspection methods. Visual inspection relies on external observation, making it less effective for identifying hidden damages or wear in complex engine parts. Utilizing endoscope inspection in car type inspection methods significantly enhances accuracy and thoroughness in quality control processes.

What is Visual Inspection in Automotive?

Visual inspection in automotive refers to the process of examining vehicle components and systems using the naked eye or basic tools to detect surface defects, corrosion, or misalignments. This method is widely used for quick checks of paint quality, weld seams, and general assembly conditions without requiring specialized equipment. Compared to endoscope inspection, visual inspection is limited to accessible and visible areas, making it less effective for identifying hidden defects inside confined or complex parts.

Understanding Endoscope Inspection

Endoscope inspection enables detailed internal examination of hard-to-reach areas, providing high-resolution images that surpass the limitations of standard visual inspection. This method improves defect detection accuracy in machinery, pipelines, and medical diagnostics by revealing hidden faults without disassembly. The ability to capture real-time video and magnified views significantly enhances maintenance efficiency and reduces downtime.

Key Differences Between Endoscope and Visual Inspection

Endoscope inspection involves using a flexible, camera-equipped device to access and visualize internal areas that are otherwise unreachable, providing high-resolution, real-time images for detailed analysis. Visual inspection relies on the inspector's direct line of sight and is limited to surface-level examination, often restricted by lighting and accessibility constraints. Key differences include endoscope inspection's ability to detect hidden defects and provide comprehensive documentation, while visual inspection is faster and requires minimal equipment but may miss critical internal issues.

Accuracy Comparison: Endoscope vs Visual Inspection

Endoscope inspection offers significantly higher accuracy compared to traditional visual inspection by enabling detailed internal views of otherwise inaccessible areas, reducing the risk of missing defects. Endoscopes provide magnified, high-resolution imagery that allows for precise identification and assessment of minute faults, unlike visual inspection which relies heavily on line-of-sight and operator subjectivity. This enhanced accuracy translates to improved defect detection rates and more reliable maintenance outcomes in fields such as aerospace, automotive, and medical equipment.

Accessibility: Hard-to-Reach Areas in Car Inspection

Endoscope inspection significantly enhances accessibility by allowing inspectors to view hard-to-reach areas within a car, such as inside engine components, exhaust systems, and behind body panels. Traditional visual inspection is limited by direct line-of-sight and often requires disassembly to examine concealed parts. Using an endoscope reduces inspection time and increases accuracy by providing real-time, high-resolution images in confined spaces that are otherwise inaccessible.

Speed and Efficiency in Inspection Techniques

Endoscope inspection offers significantly faster identification of internal defects compared to traditional visual inspection, reducing the overall inspection time by up to 50%. Enhanced magnification and targeted illumination in endoscope techniques improve efficiency by enabling precise detection of hard-to-reach areas in complex machinery. Visual inspection often relies on manual observation, which can be slower and less consistent, making endoscope inspection the preferred method for high-speed, efficient quality control processes.

Cost Implications of Both Inspection Methods

Endoscope inspection incurs higher initial costs due to specialized equipment and training requirements, but it provides detailed internal imaging that reduces the likelihood of missed defects and costly rework. Visual inspection generally involves lower upfront expenses but often leads to increased operational costs over time from potential undetected flaws and more frequent maintenance interventions. Organizations balancing short-term budget constraints with long-term quality assurance may find endoscope inspection to be more cost-effective despite its higher initial investment.

Use Cases: When to Choose Endoscope or Visual Inspection

Endoscope inspection excels in detailed internal examination of complex machinery, pipelines, and hard-to-reach areas where visual inspection is limited by accessibility and lighting. Visual inspection is ideal for quick, surface-level assessments of large, accessible components where structural integrity and surface conditions are the primary focus. Choosing between endoscope and visual inspection depends on the need for internal visibility versus speed and simplicity in evaluation tasks.

Future Trends in Automotive Inspection Technology

Endoscope inspection offers enhanced precision and access to confined automotive components compared to traditional visual inspection methods, enabling early detection of defects such as cracks and corrosion. Future trends in automotive inspection technology emphasize integrating artificial intelligence and machine learning algorithms with endoscopic imaging to automate defect recognition and improve diagnostic accuracy. These advancements will significantly reduce inspection times and increase reliability in quality control processes across the automotive industry.

Endoscope inspection vs visual inspection Infographic

cardiffo.com

cardiffo.com