Chassis inspection involves checking the vehicle's frame, suspension, and structural integrity to ensure safety and proper alignment, while engine inspection focuses on evaluating the engine's performance, fluid levels, and mechanical components for optimal operation. Thorough chassis inspections detect damage or corrosion that could compromise vehicle stability, whereas engine inspections identify issues such as leaks, wear, or malfunctions that affect power and efficiency. Both inspections are essential for comprehensive vehicle maintenance, prioritizing different critical systems to maintain overall functionality and safety.

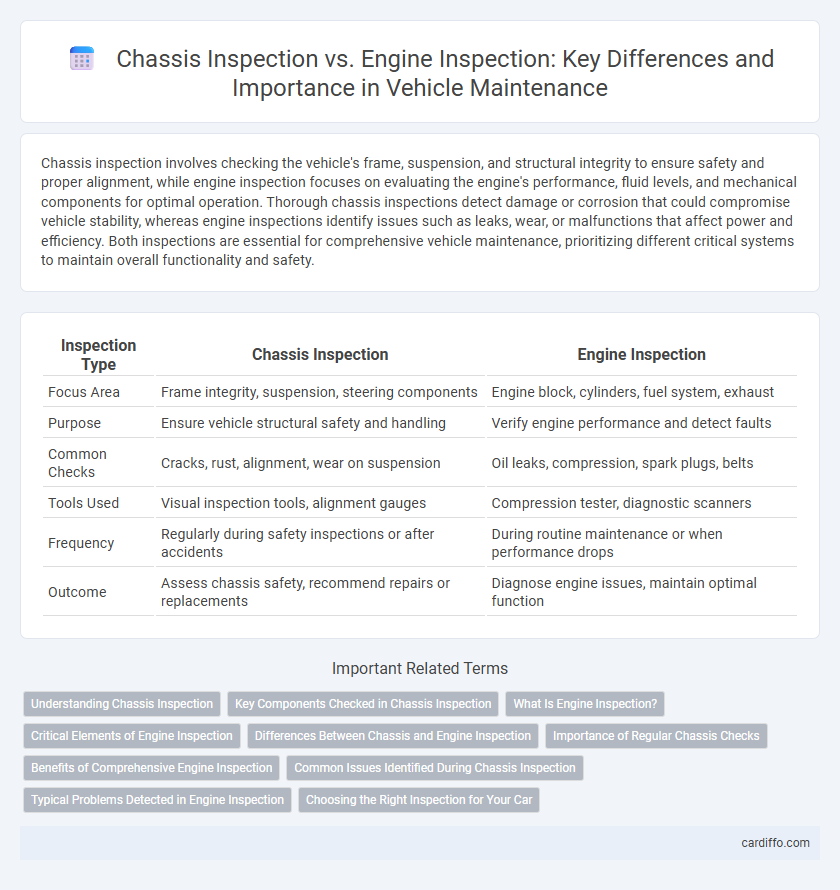

Table of Comparison

| Inspection Type | Chassis Inspection | Engine Inspection |

|---|---|---|

| Focus Area | Frame integrity, suspension, steering components | Engine block, cylinders, fuel system, exhaust |

| Purpose | Ensure vehicle structural safety and handling | Verify engine performance and detect faults |

| Common Checks | Cracks, rust, alignment, wear on suspension | Oil leaks, compression, spark plugs, belts |

| Tools Used | Visual inspection tools, alignment gauges | Compression tester, diagnostic scanners |

| Frequency | Regularly during safety inspections or after accidents | During routine maintenance or when performance drops |

| Outcome | Assess chassis safety, recommend repairs or replacements | Diagnose engine issues, maintain optimal function |

Understanding Chassis Inspection

Chassis inspection involves evaluating the vehicle's structural frame, suspension components, and undercarriage for damage, rust, or wear that can compromise safety and performance. This process ensures the integrity of critical parts such as control arms, bushings, and the frame rails, which are essential for vehicle stability and handling. Unlike engine inspection, which focuses on mechanical performance and powertrain condition, chassis inspection emphasizes structural soundness and the proper functioning of suspension and steering systems.

Key Components Checked in Chassis Inspection

Chassis inspection involves a detailed examination of key components such as the frame, suspension system, steering mechanism, brakes, and wheel alignment to ensure structural integrity and safe vehicle handling. Unlike engine inspection, which focuses on the powertrain, chassis inspection targets mechanical parts that contribute to vehicle stability and safety. Regular chassis checks help detect wear, corrosion, and damage that could affect overall performance and safety on the road.

What Is Engine Inspection?

Engine inspection involves a thorough examination of the engine's components, such as the cylinders, pistons, valves, and fuel system, to ensure optimal performance and identify potential issues. This process includes checking for leaks, wear, and proper lubrication while assessing engine compression and timing for efficient operation. Engine inspection is critical for preventing breakdowns and maintaining vehicle safety and fuel efficiency.

Critical Elements of Engine Inspection

Engine inspection prioritizes critical elements such as the condition of pistons, cylinder heads, valves, and timing belts to ensure optimal performance and prevent mechanical failures. Precision in evaluating oil levels, coolant systems, and fuel injectors is essential to detect wear and leaks that could compromise engine efficiency. Unlike chassis inspection, which focuses on structural integrity and suspension components, engine inspection demands detailed analysis of internal mechanical parts and fluid systems for reliable operation.

Differences Between Chassis and Engine Inspection

Chassis inspection primarily focuses on evaluating the vehicle's structural frame, suspension system, and steering components for wear, damage, or corrosion, ensuring stability and safety. Engine inspection concentrates on assessing the mechanical and electrical parts such as the fuel system, ignition, belts, and cooling systems to maintain optimal performance and prevent breakdowns. The key difference lies in the chassis inspection targeting the vehicle's foundation and motion support, while engine inspection centers on power generation and mechanical efficiency.

Importance of Regular Chassis Checks

Regular chassis inspections are crucial for vehicle safety, ensuring structural integrity and preventing frame damage that could lead to costly repairs or accidents. Unlike engine inspections that focus on mechanical performance, chassis checks detect issues in components such as suspension, steering, and mounting points, which directly impact handling and stability. Consistent chassis maintenance prolongs vehicle lifespan, enhances driving comfort, and safeguards occupants by identifying corrosion, cracks, or misalignment early.

Benefits of Comprehensive Engine Inspection

Comprehensive engine inspection identifies early signs of wear, preventing costly breakdowns and extending engine lifespan. Detecting issues like oil leaks, worn belts, or spark plug malfunctions ensures optimal engine performance and fuel efficiency. Regular engine inspections enhance vehicle safety and reliability by addressing critical components before failures occur.

Common Issues Identified During Chassis Inspection

Common issues identified during chassis inspection include worn suspension components, corrosion on the frame, and damaged or loose bolts that compromise structural integrity. Inspectors often detect cracks in the chassis, misalignment, and issues with mounting points that can affect vehicle safety and handling. These problems contrast with engine inspection, which primarily targets mechanical failures, fluid leaks, and performance defects.

Typical Problems Detected in Engine Inspection

Engine inspection typically detects issues such as oil leaks, worn-out spark plugs, and coolant system failures. Problems like engine misfires, unusual noises, and overheating are also common indicators of engine health. Identifying these faults early during an engine inspection prevents costly repairs and ensures optimal vehicle performance.

Choosing the Right Inspection for Your Car

Choosing the right inspection for your car depends on identifying specific vehicle concerns and maintenance goals. Chassis inspection focuses on the structural integrity of the frame, suspension components, and undercarriage, crucial for safety and handling performance. Engine inspection targets the powertrain's health, assessing components such as the fuel system, cooling system, and engine diagnostics to ensure optimal performance and prevent breakdowns.

Chassis Inspection vs Engine Inspection Infographic

cardiffo.com

cardiffo.com