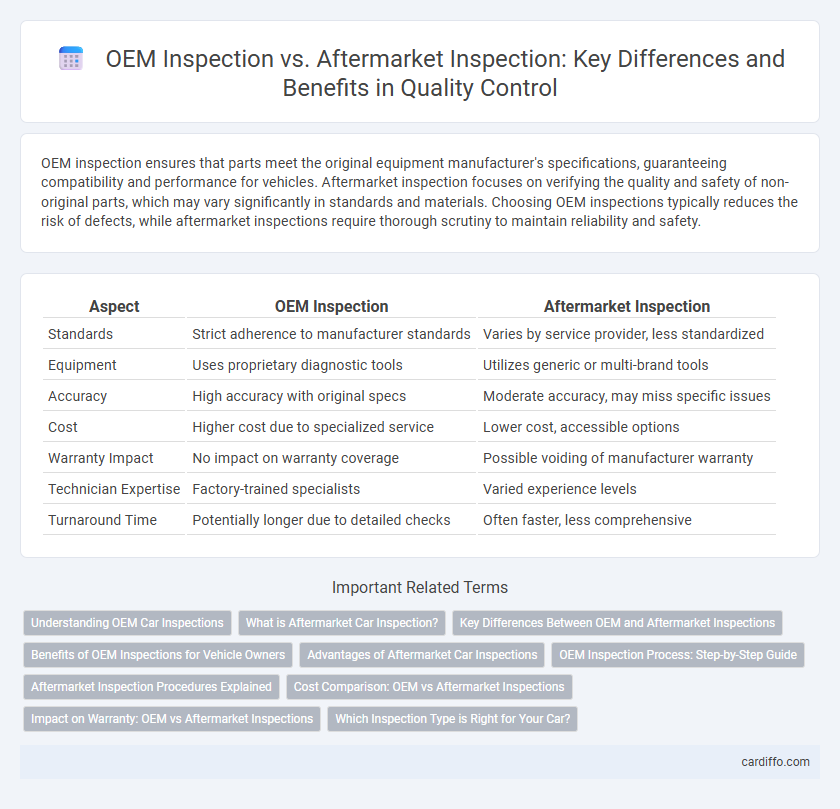

OEM inspection ensures that parts meet the original equipment manufacturer's specifications, guaranteeing compatibility and performance for vehicles. Aftermarket inspection focuses on verifying the quality and safety of non-original parts, which may vary significantly in standards and materials. Choosing OEM inspections typically reduces the risk of defects, while aftermarket inspections require thorough scrutiny to maintain reliability and safety.

Table of Comparison

| Aspect | OEM Inspection | Aftermarket Inspection |

|---|---|---|

| Standards | Strict adherence to manufacturer standards | Varies by service provider, less standardized |

| Equipment | Uses proprietary diagnostic tools | Utilizes generic or multi-brand tools |

| Accuracy | High accuracy with original specs | Moderate accuracy, may miss specific issues |

| Cost | Higher cost due to specialized service | Lower cost, accessible options |

| Warranty Impact | No impact on warranty coverage | Possible voiding of manufacturer warranty |

| Technician Expertise | Factory-trained specialists | Varied experience levels |

| Turnaround Time | Potentially longer due to detailed checks | Often faster, less comprehensive |

Understanding OEM Car Inspections

OEM car inspections are conducted using manufacturer-specific protocols, ensuring that every component meets original design and safety standards. These inspections use proprietary diagnostic tools to verify vehicle performance, preserving warranty validity and enhancing reliability. Compared to aftermarket inspections, OEM evaluations provide more accurate assessments tailored to the car's make and model, reducing risks of undetected defects.

What is Aftermarket Car Inspection?

Aftermarket car inspection involves evaluating vehicles or parts that have been modified or replaced with non-original equipment manufacturer (OEM) components, ensuring they meet safety and performance standards. This inspection checks for quality, compatibility, and potential issues arising from aftermarket installations, often affecting warranty and resale value. Compared to OEM inspections, aftermarket inspections focus on the integrity and reliability of parts not produced by the original vehicle manufacturer.

Key Differences Between OEM and Aftermarket Inspections

OEM inspections adhere strictly to manufacturer specifications and use original equipment standards to ensure product quality and safety. Aftermarket inspections focus on compatibility and performance with third-party components, often emphasizing cost-effectiveness and customization. Key differences include inspection criteria, testing protocols, and certification processes tailored to either original or aftermarket parts.

Benefits of OEM Inspections for Vehicle Owners

OEM inspections provide vehicle owners with precise assessments based on manufacturer standards, ensuring optimal performance and safety. These inspections utilize OEM-specific diagnostic tools and genuine parts, eliminating compatibility issues and enhancing vehicle longevity. Relying on OEM inspections helps maintain warranty validity and preserves the vehicle's resale value.

Advantages of Aftermarket Car Inspections

Aftermarket car inspections provide a comprehensive evaluation of vehicle condition beyond manufacturer standards, identifying wear and repairs often missed during OEM inspections. These inspections offer flexibility with tailored checklists that address specific user concerns, ensuring better cost efficiency and extended vehicle lifespan. Leveraging independent inspection services enhances transparency, helping buyers and owners make informed maintenance and resale decisions.

OEM Inspection Process: Step-by-Step Guide

OEM inspection process involves a systematic step-by-step approach to ensure product quality and compliance with original equipment manufacturer standards. The process typically starts with raw material verification, followed by in-process inspections, functional testing, and final product evaluation using precise measurement tools and quality control protocols. This method guarantees that each component meets strict specifications, reducing defects and maintaining the integrity of the original design.

Aftermarket Inspection Procedures Explained

Aftermarket inspection procedures involve thorough evaluations of components post-manufacture to ensure compliance with safety and performance standards, often focusing on wear, damage, and compatibility with existing systems. These inspections utilize specialized tools and diagnostic techniques to detect issues that may not be covered during OEM inspections, which primarily concentrate on design specifications and initial manufacturing quality. Emphasizing preventative maintenance and defect identification, aftermarket inspections play a critical role in extending equipment lifespan and maintaining operational reliability.

Cost Comparison: OEM vs Aftermarket Inspections

OEM inspections typically incur higher costs due to the use of original manufacturer parts and certified technicians, ensuring compliance with strict quality standards. Aftermarket inspections often offer more affordable pricing by utilizing third-party components and flexible service options, though they may vary in reliability. Cost comparison reveals that while OEM inspections provide guaranteed authenticity, aftermarket inspections present a cost-effective alternative for routine maintenance.

Impact on Warranty: OEM vs Aftermarket Inspections

OEM inspections maintain warranty validity by adhering to manufacturer standards and using certified parts, ensuring repairs meet original specifications. Aftermarket inspections may risk voiding the warranty due to the use of non-certified parts or deviation from OEM guidelines. Choosing OEM inspections provides assurance of compliance with warranty requirements, reducing potential disputes and costly repairs.

Which Inspection Type is Right for Your Car?

OEM inspection ensures your vehicle meets the original manufacturer's specifications, maintaining warranty integrity and optimal performance. Aftermarket inspection offers more flexible, cost-effective evaluation options that can identify issues beyond factory standards, suitable for older or modified vehicles. Choosing the right inspection depends on your car's age, warranty status, and whether you prioritize factory-approved parts or customized assessments.

OEM inspection vs aftermarket inspection Infographic

cardiffo.com

cardiffo.com