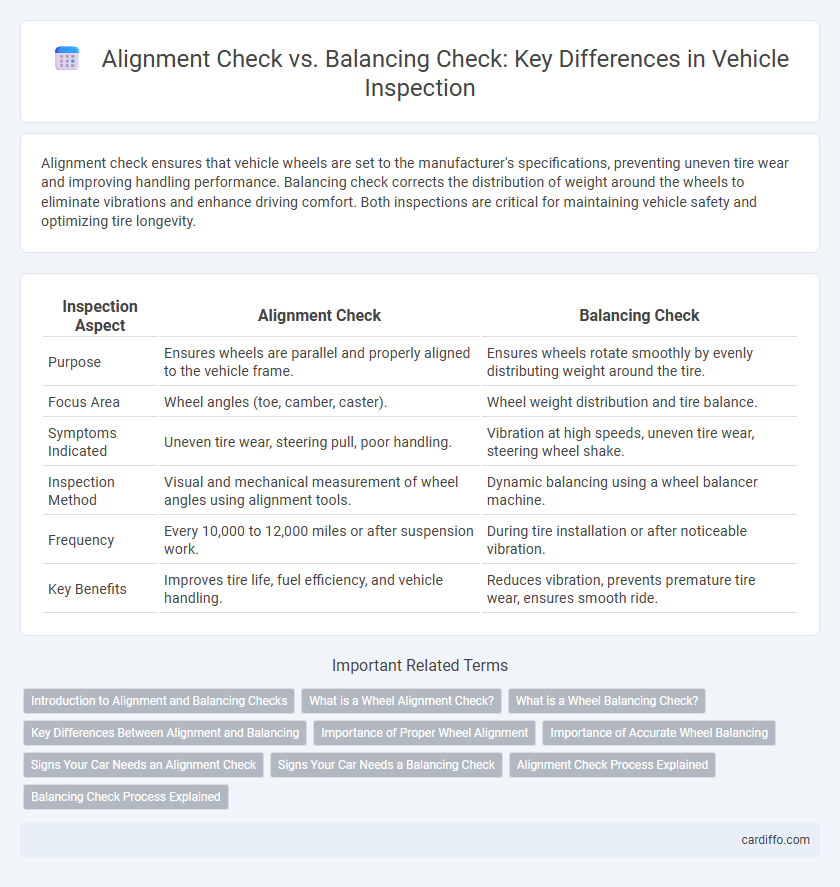

Alignment check ensures that vehicle wheels are set to the manufacturer's specifications, preventing uneven tire wear and improving handling performance. Balancing check corrects the distribution of weight around the wheels to eliminate vibrations and enhance driving comfort. Both inspections are critical for maintaining vehicle safety and optimizing tire longevity.

Table of Comparison

| Inspection Aspect | Alignment Check | Balancing Check |

|---|---|---|

| Purpose | Ensures wheels are parallel and properly aligned to the vehicle frame. | Ensures wheels rotate smoothly by evenly distributing weight around the tire. |

| Focus Area | Wheel angles (toe, camber, caster). | Wheel weight distribution and tire balance. |

| Symptoms Indicated | Uneven tire wear, steering pull, poor handling. | Vibration at high speeds, uneven tire wear, steering wheel shake. |

| Inspection Method | Visual and mechanical measurement of wheel angles using alignment tools. | Dynamic balancing using a wheel balancer machine. |

| Frequency | Every 10,000 to 12,000 miles or after suspension work. | During tire installation or after noticeable vibration. |

| Key Benefits | Improves tire life, fuel efficiency, and vehicle handling. | Reduces vibration, prevents premature tire wear, ensures smooth ride. |

Introduction to Alignment and Balancing Checks

Alignment checks assess the correct positioning of vehicle wheels relative to each other and the frame to prevent uneven tire wear and ensure optimal handling. Balancing checks focus on distributing the weight around the wheel and tire assembly evenly to eliminate vibrations and extend tire life. Both procedures are crucial for maintaining vehicle safety, performance, and ride comfort.

What is a Wheel Alignment Check?

A wheel alignment check measures and adjusts the angles of the wheels to the manufacturer's specifications, ensuring proper tire contact with the road. It focuses on camber, caster, and toe angles to prevent uneven tire wear and improve vehicle handling. Regular alignment checks enhance fuel efficiency and extend tire life by maintaining optimal steering and suspension geometry.

What is a Wheel Balancing Check?

A wheel balancing check ensures that the weight of the wheel and tire is evenly distributed around the axle, preventing vibrations and uneven tire wear. This inspection identifies imbalances caused by heavy spots on the tire or wheel, which can lead to steering issues and reduced vehicle stability. Balancing is performed using specialized machines that spin the wheel to detect weight discrepancies, allowing technicians to add counterweights for optimal performance.

Key Differences Between Alignment and Balancing

Alignment check focuses on adjusting the angles of the wheels to match the manufacturer's specifications, ensuring proper tire contact with the road and preventing uneven tire wear. Balancing check involves distributing the weight of the wheel and tire assembly evenly around the axle to eliminate vibrations and improve ride quality. Key differences include alignment correcting directional angles such as camber, caster, and toe, while balancing addresses weight distribution to prevent wobbling and uneven tire wear.

Importance of Proper Wheel Alignment

Proper wheel alignment ensures that tires make optimal contact with the road, reducing uneven tire wear and improving vehicle handling. Alignment checks detect misalignments in the suspension geometry, which can prevent steering issues and enhance fuel efficiency. Unlike balancing checks that address tire vibrations by distributing weight evenly on the wheel, alignment maintains directional stability for safer and smoother driving.

Importance of Accurate Wheel Balancing

Accurate wheel balancing is essential to prevent vibrations, reduce tire wear, and ensure smooth vehicle operation, distinguishing it clearly from alignment checks that primarily address wheel angles. Proper balancing allocates weight evenly around the wheel, enhancing driving stability and extending suspension component life. Neglecting precise wheel balancing can lead to uneven tire degradation and increased fuel consumption, underscoring the importance of regular inspections.

Signs Your Car Needs an Alignment Check

Uneven tire wear, steering wheel drifting to one side, and vibrations at higher speeds are key signs your car needs an alignment check. Misaligned wheels cause poor handling and increased tire damage, whereas balancing check focuses on reducing vibrations caused by uneven tire weight distribution. Timely alignment inspection prevents costly repairs and improves overall vehicle safety and fuel efficiency.

Signs Your Car Needs a Balancing Check

Uneven tire wear, steering wheel vibration at high speeds, and pulling to one side while driving are clear signs your car needs a balancing check. Imbalanced tires cause uneven weight distribution, leading to premature tire wear and decreased fuel efficiency. Unlike an alignment check that adjusts angles for proper tire contact, balancing ensures the tires and wheels spin smoothly without causing vibrations.

Alignment Check Process Explained

Alignment check involves precisely measuring and adjusting the angles of wheels to the manufacturer's specifications to ensure proper contact with the road surface. The process includes using specialized equipment such as laser alignment systems or computerized sensors to detect deviations in camber, caster, and toe angles. Proper alignment improves vehicle handling, reduces tire wear, and enhances overall safety during operation.

Balancing Check Process Explained

Balancing check involves measuring and correcting the distribution of mass in rotating components to reduce vibrations and improve performance. The process typically includes attaching sensors to detect imbalance, spinning the component at operational speeds, and using specialized equipment to apply counterweights or make adjustments. Proper balancing enhances machinery longevity, efficiency, and safety by minimizing wear and tear caused by uneven forces.

Alignment Check vs Balancing Check Infographic

cardiffo.com

cardiffo.com