Fluid leak inspection identifies issues like oil, coolant, or brake fluid leaks that can cause engine damage or safety hazards. Electrical system inspection detects problems with wiring, battery, alternator, and sensors essential for vehicle operation and preventing breakdowns. Both inspections are crucial for maintaining optimal vehicle performance and safety but target different underlying issues.

Table of Comparison

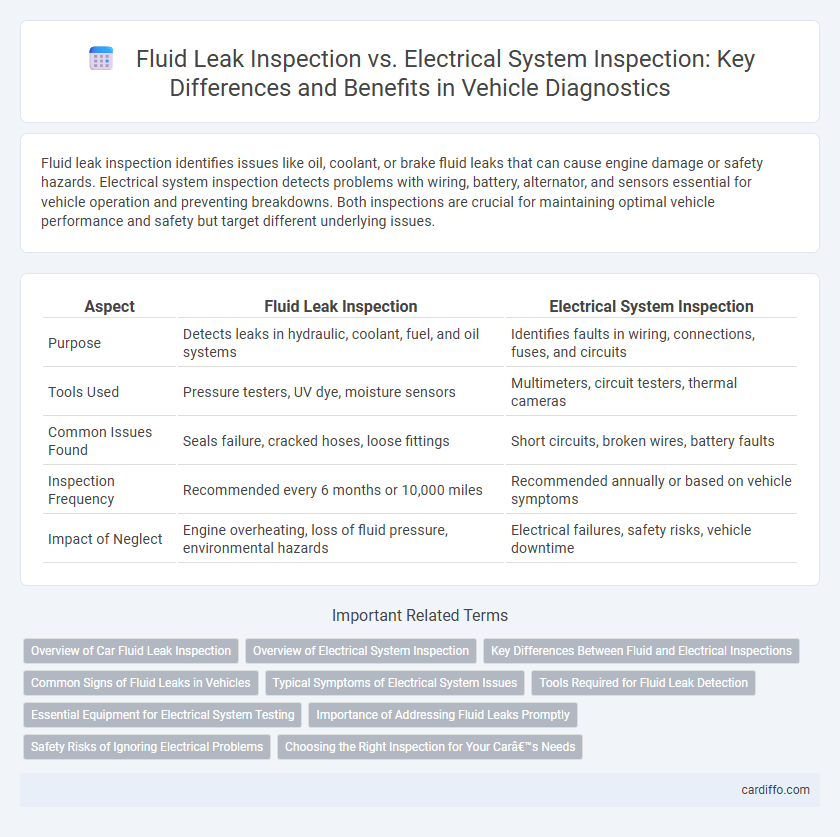

| Aspect | Fluid Leak Inspection | Electrical System Inspection |

|---|---|---|

| Purpose | Detects leaks in hydraulic, coolant, fuel, and oil systems | Identifies faults in wiring, connections, fuses, and circuits |

| Tools Used | Pressure testers, UV dye, moisture sensors | Multimeters, circuit testers, thermal cameras |

| Common Issues Found | Seals failure, cracked hoses, loose fittings | Short circuits, broken wires, battery faults |

| Inspection Frequency | Recommended every 6 months or 10,000 miles | Recommended annually or based on vehicle symptoms |

| Impact of Neglect | Engine overheating, loss of fluid pressure, environmental hazards | Electrical failures, safety risks, vehicle downtime |

Overview of Car Fluid Leak Inspection

Car fluid leak inspection involves identifying and locating leaks in essential vehicle fluids such as engine oil, coolant, brake fluid, transmission fluid, and power steering fluid. Detecting fluid leaks early prevents engine damage, overheating, brake failure, and transmission issues, ensuring overall vehicle safety and performance. This inspection typically includes checking under the car, around seals, hoses, and fluid reservoirs using visual and pressure tests to pinpoint leaks efficiently.

Overview of Electrical System Inspection

Electrical system inspection involves a thorough examination of wiring, connectors, circuit breakers, and electrical components to identify potential faults such as short circuits, corrosion, or insulation damage. This inspection ensures proper functionality, safety, and compliance with industry standards by detecting issues that could lead to equipment failure or fire hazards. Advanced diagnostic tools like multimeters and thermal cameras are commonly used to assess voltage levels, current flow, and temperature anomalies within electrical systems.

Key Differences Between Fluid and Electrical Inspections

Fluid leak inspection primarily involves identifying sources of liquid leakage, such as oil, coolant, or hydraulic fluid, by checking seals, hoses, and connectors for cracks or wear. Electrical system inspection focuses on diagnosing wiring integrity, voltage continuity, and component functionality to prevent shorts, corrosion, or power loss. Key differences include the nature of defects detected--visible fluid leaks versus electrical faults--and the tools used, with fluid inspections relying on visual and pressure tests, while electrical inspections use multimeters and circuit analyzers.

Common Signs of Fluid Leaks in Vehicles

Common signs of fluid leaks in vehicles include visible puddles or stains under the car, a strong odor of fuel or coolant, and a noticeable drop in fluid levels such as engine oil, brake fluid, or transmission fluid. Fluid that appears dark, oily, or has a strong chemical smell often indicates a leak requiring immediate attention. Early detection through regular fluid leak inspections can prevent engine damage, brake failure, and costly repairs.

Typical Symptoms of Electrical System Issues

Typical symptoms of electrical system issues include flickering or dimming lights, intermittent power loss, unusual noises from electrical components, and frequent circuit breaker trips. These signs often indicate underlying problems such as faulty wiring, corroded connections, or failing electrical parts. Early detection through electrical system inspection helps prevent safety hazards and costly repairs.

Tools Required for Fluid Leak Detection

Fluid leak detection relies heavily on specialized tools such as ultrasonic leak detectors, dye kits, and infrared cameras to identify and locate leaks with precision. In contrast, electrical system inspection primarily requires multimeters, circuit testers, and oscilloscopes to diagnose faults and ensure circuit integrity. The choice of tools for fluid leak inspection emphasizes non-invasive methods that enhance accuracy and speed in detecting even the smallest leaks.

Essential Equipment for Electrical System Testing

Essential equipment for electrical system testing includes multimeters, clamp meters, insulation resistance testers, and circuit analyzers, which are crucial for accurately diagnosing faults and ensuring system safety. Fluid leak inspection tools, such as ultrasonic leak detectors and pressure gauges, differ significantly as they focus on identifying seal integrity and fluid containment issues. Proper selection of equipment tailored to electrical testing enhances fault detection efficiency and prevents potential hazards in complex electrical circuits.

Importance of Addressing Fluid Leaks Promptly

Fluid leak inspection is crucial for preventing engine damage, fire hazards, and environmental contamination, making early detection essential for vehicle safety and longevity. Unlike electrical system inspection, which focuses on preventing shorts and electrical failures, fluid leak inspections directly address risks of overheating and mechanical breakdown. Promptly addressing fluid leaks reduces costly repairs and ensures optimal performance, safeguarding overall vehicle reliability.

Safety Risks of Ignoring Electrical Problems

Ignoring electrical problems during inspections poses significant safety risks, including potential fires, electrical shocks, and system failures that can endanger lives and property. While fluid leak inspections primarily target mechanical integrity and environmental hazards, electrical system inspections are critical for identifying hidden faults that could lead to catastrophic consequences. Prioritizing electrical inspections ensures early detection of wiring issues, circuit malfunctions, and insulation degradation, enhancing overall operational safety.

Choosing the Right Inspection for Your Car’s Needs

Effective fluid leak inspection targets identifying leaks in engine oil, coolant, brake fluid, and transmission fluid, crucial for preventing engine damage and maintaining optimal vehicle performance. Electrical system inspection evaluates battery health, wiring integrity, alternator function, and lighting, essential for preventing electrical failures and ensuring safety. Choose fluid leak inspection if your vehicle shows signs of fluid drips, overheating, or performance drops; opt for electrical inspection when facing battery issues, warning lights, or intermittent electrical faults.

Fluid Leak Inspection vs Electrical System Inspection Infographic

cardiffo.com

cardiffo.com