Underbody inspection involves examining the vehicle's chassis, suspension, exhaust system, and brake components for rust, damage, or leaks, ensuring structural integrity and operational safety. Under-hood inspection focuses on the engine bay, checking fluid levels, belts, hoses, battery condition, and electrical connections to maintain optimal performance and prevent breakdowns. Both inspections are crucial for comprehensive vehicle maintenance, targeting different critical areas to enhance safety and reliability.

Table of Comparison

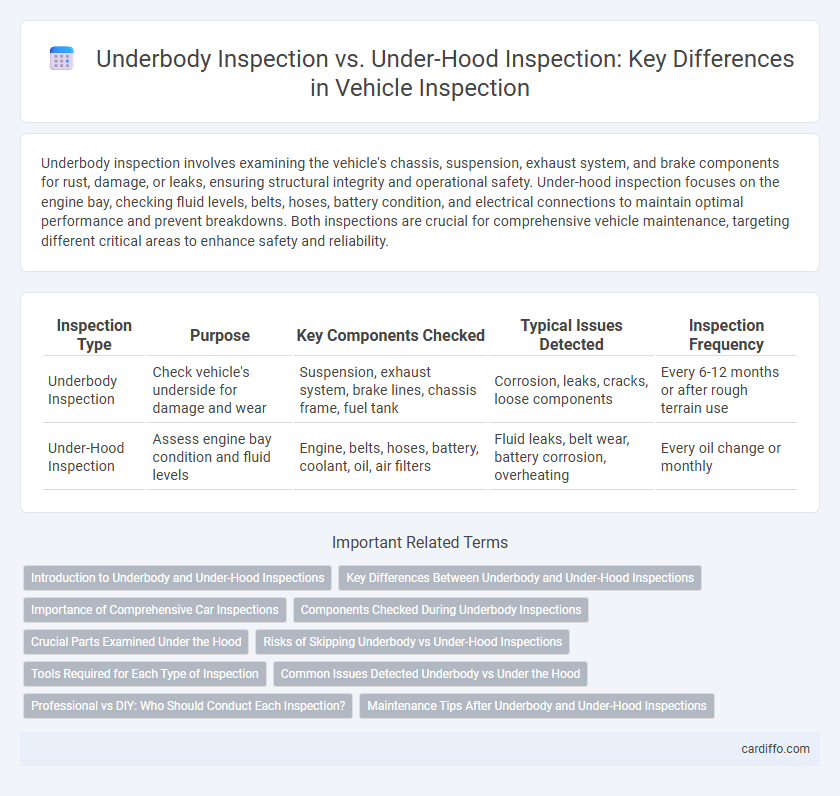

| Inspection Type | Purpose | Key Components Checked | Typical Issues Detected | Inspection Frequency |

|---|---|---|---|---|

| Underbody Inspection | Check vehicle's underside for damage and wear | Suspension, exhaust system, brake lines, chassis frame, fuel tank | Corrosion, leaks, cracks, loose components | Every 6-12 months or after rough terrain use |

| Under-Hood Inspection | Assess engine bay condition and fluid levels | Engine, belts, hoses, battery, coolant, oil, air filters | Fluid leaks, belt wear, battery corrosion, overheating | Every oil change or monthly |

Introduction to Underbody and Under-Hood Inspections

Underbody inspection involves examining the vehicle's chassis, suspension components, exhaust system, and undercarriage for damage, corrosion, or wear that may affect safety and performance. Under-hood inspection focuses on the engine compartment, checking critical elements such as the engine, belts, hoses, fluid levels, and battery for leaks, cracks, or malfunctions. Both inspections are essential for comprehensive vehicle maintenance, ensuring reliability and identifying potential issues before they escalate.

Key Differences Between Underbody and Under-Hood Inspections

Underbody inspection primarily focuses on the vehicle's chassis, suspension, exhaust system, and frame integrity, detecting issues like rust, leaks, or damage that affect structural safety and performance. Under-hood inspection targets engine components, fluid levels, belts, hoses, and electrical systems to ensure proper operation and prevent breakdowns. Key differences lie in the inspection areas--underbody emphasizes structural and mechanical elements beneath the vehicle, while under-hood concentrates on the engine compartment and related systems.

Importance of Comprehensive Car Inspections

Comprehensive car inspections encompass both underbody and under-hood checks to ensure vehicle safety and performance. Underbody inspections detect issues such as frame damage, rust, and exhaust system integrity, while under-hood inspections focus on the engine, fluid levels, and belts. Combining these inspections prevents overlooked problems, promotes early maintenance, and extends the vehicle's lifespan.

Components Checked During Underbody Inspections

Underbody inspections primarily focus on assessing the condition of the vehicle's exhaust system, suspension components, brake lines, and chassis integrity to identify rust, damage, or leaks. Special attention is given to the driveshaft, fuel lines, and protective shields to ensure all parts are secure and functioning properly. These inspections help detect issues that affect vehicle safety and performance, unlike under-hood inspections that concentrate on the engine and fluid levels.

Crucial Parts Examined Under the Hood

Under-hood inspection targets crucial components like the engine, battery, belts, hoses, and fluid reservoirs to ensure optimal vehicle performance and safety. Inspecting these parts reveals potential issues such as leaks, wear, or corrosion that can cause engine malfunction or breakdowns. Thorough under-hood examination is vital for preventive maintenance and early detection of mechanical failures.

Risks of Skipping Underbody vs Under-Hood Inspections

Skipping underbody inspections increases the risk of missing critical issues such as rust, fluid leaks, and damage to suspension components that can compromise vehicle safety and performance. Neglecting under-hood inspections can result in undetected engine problems, including faulty belts, coolant leaks, and battery corrosion, which may lead to breakdowns or costly repairs. Both inspections are essential to identify early signs of wear and prevent mechanical failures that could pose significant safety hazards.

Tools Required for Each Type of Inspection

Underbody inspection requires tools like creepers for mobility, hydraulic lifts for vehicle elevation, and specialized flashlights for visibility in tight spaces, along with inspection mirrors and corrosion detection devices. Under-hood inspection involves diagnostic scanners, multimeters for electrical testing, and a variety of hand tools such as wrenches, screwdrivers, and pliers to assess engine components, hoses, and fluid levels. Both inspections demand protective gear and thorough cleaning tools to ensure accuracy and safety during the process.

Common Issues Detected Underbody vs Under the Hood

Underbody inspections commonly detect issues such as rust, exhaust system damage, suspension wear, and fluid leaks, which are critical for vehicle safety and performance. Under-hood inspections typically reveal problems with the engine, battery, belts, hoses, and fluid levels, directly affecting vehicle operation and reliability. Both inspections are essential for comprehensive vehicle maintenance, identifying different sets of issues that contribute to overall vehicle health.

Professional vs DIY: Who Should Conduct Each Inspection?

Underbody inspections require specialized equipment like lifts and protective gear, making professional mechanics the ideal choice for thorough safety and damage assessments. Under-hood inspections can be partially performed by knowledgeable DIY enthusiasts using basic tools and vehicle manuals to check fluid levels, belts, and battery condition. Complex under-hood issues involving electrical systems or engine diagnostics are best handled by certified technicians to ensure accurate repairs and avoid further damage.

Maintenance Tips After Underbody and Under-Hood Inspections

Perform thorough cleaning and rust prevention after underbody inspection to maintain vehicle longevity and avoid corrosion. Following an under-hood inspection, regularly check fluid levels, belts, and hoses for wear or leaks to ensure engine performance. Scheduling timely lubrication and replacing worn components based on inspection findings optimize overall vehicle reliability and safety.

Underbody inspection vs under-hood inspection Infographic

cardiffo.com

cardiffo.com