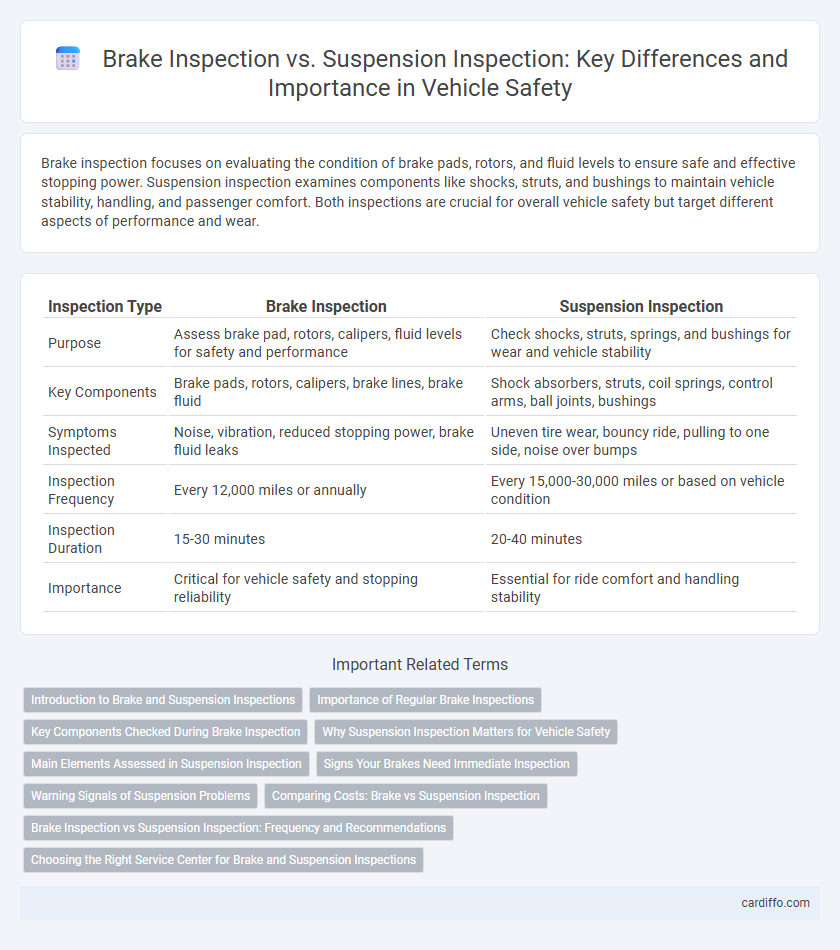

Brake inspection focuses on evaluating the condition of brake pads, rotors, and fluid levels to ensure safe and effective stopping power. Suspension inspection examines components like shocks, struts, and bushings to maintain vehicle stability, handling, and passenger comfort. Both inspections are crucial for overall vehicle safety but target different aspects of performance and wear.

Table of Comparison

| Inspection Type | Brake Inspection | Suspension Inspection |

|---|---|---|

| Purpose | Assess brake pad, rotors, calipers, fluid levels for safety and performance | Check shocks, struts, springs, and bushings for wear and vehicle stability |

| Key Components | Brake pads, rotors, calipers, brake lines, brake fluid | Shock absorbers, struts, coil springs, control arms, ball joints, bushings |

| Symptoms Inspected | Noise, vibration, reduced stopping power, brake fluid leaks | Uneven tire wear, bouncy ride, pulling to one side, noise over bumps |

| Inspection Frequency | Every 12,000 miles or annually | Every 15,000-30,000 miles or based on vehicle condition |

| Inspection Duration | 15-30 minutes | 20-40 minutes |

| Importance | Critical for vehicle safety and stopping reliability | Essential for ride comfort and handling stability |

Introduction to Brake and Suspension Inspections

Brake inspections evaluate the condition of brake pads, rotors, calipers, and fluid levels to ensure optimal stopping power and safety. Suspension inspections assess shocks, struts, springs, and control arms to maintain vehicle stability, handling, and ride comfort. Regular inspections of both systems are critical for preventing mechanical failures and enhancing overall driving performance.

Importance of Regular Brake Inspections

Regular brake inspections are crucial for maintaining vehicle safety by ensuring the braking system functions effectively to prevent accidents. Brake inspections identify worn brake pads, fluid leaks, and rotor damage early, reducing the risk of brake failure and costly repairs. While suspension inspection enhances ride comfort and handling, prioritizing brake inspections directly impacts critical safety and vehicle performance.

Key Components Checked During Brake Inspection

Brake inspection primarily focuses on key components such as brake pads, rotors, calipers, brake lines, and the master cylinder to ensure effective stopping power and safety. Technicians check for wear, thickness, fluid levels, and potential leaks that could compromise braking performance. This contrasts with suspension inspection, which targets parts like shocks, struts, springs, and control arms to maintain vehicle stability and ride comfort.

Why Suspension Inspection Matters for Vehicle Safety

Suspension inspection is crucial for vehicle safety because it ensures proper handling, stability, and tire contact with the road, reducing the risk of accidents caused by loss of control. Unlike brake inspection, which focuses on stopping power, suspension checks identify worn shocks, struts, and components that affect ride quality and steering response. Regular suspension inspection helps prevent uneven tire wear and improves overall vehicle performance, directly contributing to safer driving conditions.

Main Elements Assessed in Suspension Inspection

Suspension inspection primarily assesses shock absorbers, struts, springs, control arms, and bushings for wear, damage, or leaks that impact vehicle stability and ride comfort. Brake inspection focuses on evaluating brake pads, rotors, calipers, and hydraulic fluid to ensure effective stopping power. Emphasizing suspension components highlights the importance of maintaining alignment, handling, and vibration control for overall safety.

Signs Your Brakes Need Immediate Inspection

Squeaking, grinding noises, or a spongy brake pedal are clear signs your brakes need immediate inspection to prevent potential failure. Uneven brake pad wear or increased stopping distances also signal urgent attention to the braking system. While suspension inspection focuses on ride quality and handling, brake inspection ensures safety by addressing critical stopping power issues.

Warning Signals of Suspension Problems

Warning signals of suspension problems include uneven tire wear, excessive bouncing, and pulling to one side while driving. These indicators differ from brake inspection signs, which focus on squealing noises, reduced stopping power, and brake pedal vibrations. Early detection of suspension issues ensures vehicle stability and safety, preventing further damage to alignment and tires.

Comparing Costs: Brake vs Suspension Inspection

Brake inspection costs typically range from $50 to $100, reflecting the labor and diagnostic time needed to assess brake pad thickness, rotor condition, and hydraulic system integrity. Suspension inspections often run higher, between $100 and $200, due to the complexity of evaluating struts, shocks, ball joints, and alignment components. Cost differences stem from the scope of parts evaluated and diagnostic equipment required for comprehensive suspension assessments versus brake system evaluations.

Brake Inspection vs Suspension Inspection: Frequency and Recommendations

Brake inspections should be performed every 10,000 to 15,000 miles or annually to ensure optimal stopping performance and safety. Suspension inspections are typically recommended every 50,000 miles or during tire rotations to identify worn shocks, struts, and alignment issues. Regular brake inspections prevent brake failure, while suspension inspections maintain ride comfort and vehicle handling.

Choosing the Right Service Center for Brake and Suspension Inspections

Selecting the right service center for brake and suspension inspections ensures accurate diagnosis and quality repairs using specialized tools and certified technicians. Brake inspections demand precise assessment of pads, rotors, and hydraulic components, while suspension inspections require expertise in shocks, struts, and alignment systems. Choosing a facility with experience in both systems guarantees safety, optimal vehicle performance, and long-lasting service outcomes.

Brake inspection vs suspension inspection Infographic

cardiffo.com

cardiffo.com