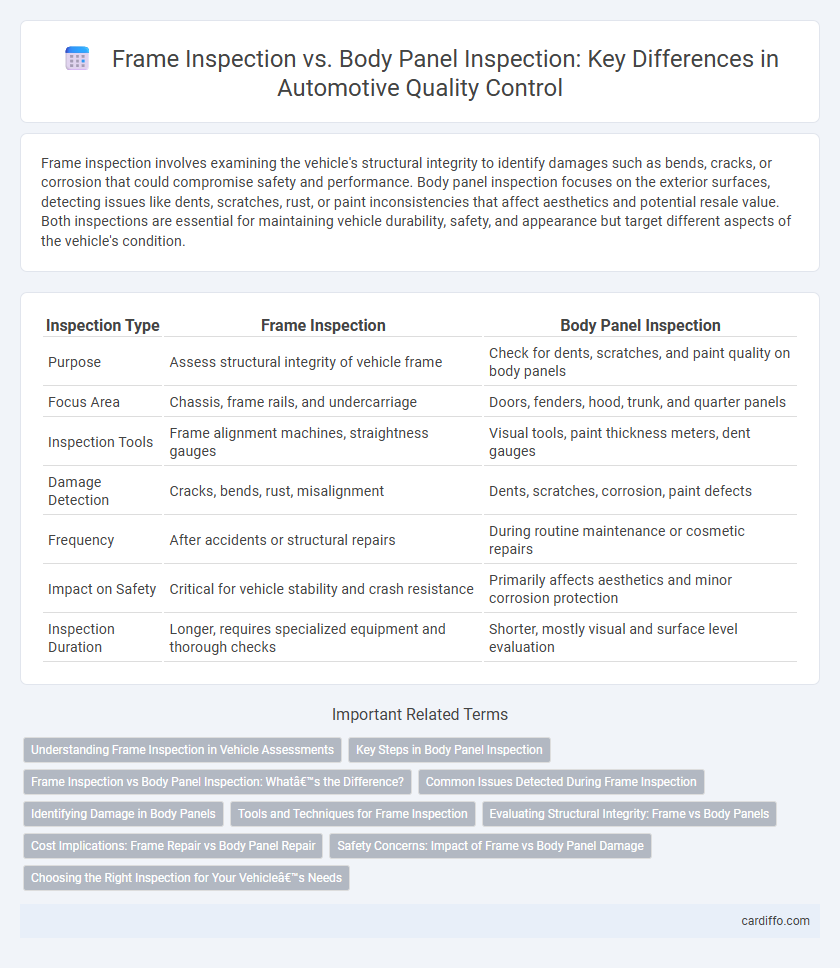

Frame inspection involves examining the vehicle's structural integrity to identify damages such as bends, cracks, or corrosion that could compromise safety and performance. Body panel inspection focuses on the exterior surfaces, detecting issues like dents, scratches, rust, or paint inconsistencies that affect aesthetics and potential resale value. Both inspections are essential for maintaining vehicle durability, safety, and appearance but target different aspects of the vehicle's condition.

Table of Comparison

| Inspection Type | Frame Inspection | Body Panel Inspection |

|---|---|---|

| Purpose | Assess structural integrity of vehicle frame | Check for dents, scratches, and paint quality on body panels |

| Focus Area | Chassis, frame rails, and undercarriage | Doors, fenders, hood, trunk, and quarter panels |

| Inspection Tools | Frame alignment machines, straightness gauges | Visual tools, paint thickness meters, dent gauges |

| Damage Detection | Cracks, bends, rust, misalignment | Dents, scratches, corrosion, paint defects |

| Frequency | After accidents or structural repairs | During routine maintenance or cosmetic repairs |

| Impact on Safety | Critical for vehicle stability and crash resistance | Primarily affects aesthetics and minor corrosion protection |

| Inspection Duration | Longer, requires specialized equipment and thorough checks | Shorter, mostly visual and surface level evaluation |

Understanding Frame Inspection in Vehicle Assessments

Frame inspection in vehicle assessments evaluates the structural integrity of the chassis, identifying damage or corrosion that may compromise safety and performance. Unlike body panel inspection, which focuses on surface-level dents, scratches, and paint issues, frame inspection requires detailed analysis using equipment such as frame straightening machines and computerized measuring systems. Accurate frame inspection ensures the vehicle meets safety standards and maintains proper alignment, critical for both accident repair and resale value.

Key Steps in Body Panel Inspection

Body panel inspection involves critical steps such as visual examination for dents, scratches, and corrosion, followed by tactile assessment to detect uneven surfaces or misalignments. Precision measurements using calibrated tools ensure panel dimensions meet manufacturer specifications, while adherence to OEM standards helps identify structural defects or replacement needs. Documenting findings and comparing with frame inspection results provides a comprehensive understanding of vehicle integrity and safety.

Frame Inspection vs Body Panel Inspection: What’s the Difference?

Frame inspection assesses the structural integrity and alignment of a vehicle's chassis, crucial for safety and crashworthiness. Body panel inspection focuses on the exterior surfaces to identify dents, rust, paint defects, and corrosion that affect appearance and aerodynamics. Understanding the differences ensures proper maintenance and repair prioritization for vehicle durability and performance.

Common Issues Detected During Frame Inspection

Frame inspection commonly detects issues such as structural cracks, rust corrosion, and misalignment caused by accidents or prolonged wear. These defects compromise the vehicle's safety and can lead to uneven tire wear, poor handling, and reduced crashworthiness. Identifying such problems early through frame inspection is crucial for effective repairs and maintaining vehicle integrity.

Identifying Damage in Body Panels

Frame inspection primarily targets structural integrity, detecting bends, cracks, or misalignments in the vehicle's chassis that compromise safety. Body panel inspection focuses on identifying surface-level damage including dents, rust spots, scratches, and paint deterioration that affect aesthetic appeal and corrosion resistance. Accurate identification of body panel damage is crucial for precise repair estimates and restoring the vehicle's appearance and protection against environmental elements.

Tools and Techniques for Frame Inspection

Frame inspection utilizes advanced tools such as digital measuring systems, laser scanning, and frame alignment machines to detect structural distortions with high precision. Techniques include computerized tomography and laser-based deformation analysis, enabling accurate assessment of frame integrity and alignment. These methods surpass traditional visual inspection used in body panel checks by providing quantifiable data on frame geometry and damage extent.

Evaluating Structural Integrity: Frame vs Body Panels

Frame inspection evaluates the core structural integrity of a vehicle by assessing key components like the chassis and subframe for cracks, bends, or corrosion that could compromise safety. Body panel inspection focuses on surface-level damage such as dents, rust, or misalignment affecting the vehicle's exterior but not necessarily its overall rigidity. Prioritizing frame inspection is crucial for identifying foundational issues that impact crashworthiness, while body panel inspection ensures aesthetic quality and minor structural alignment.

Cost Implications: Frame Repair vs Body Panel Repair

Frame repair typically incurs higher costs than body panel repair due to the complexity of restoring structural integrity and the need for specialized equipment. Body panel repair often involves less labor-intensive procedures such as dent removal or panel replacement, resulting in lower expenses. Insurance premiums and vehicle resale value can be more adversely affected by frame damage compared to body panel issues, influencing overall cost implications.

Safety Concerns: Impact of Frame vs Body Panel Damage

Frame inspection is critical because damage to the vehicle's frame can compromise structural integrity, leading to severe safety risks such as reduced crash protection and alignment issues. Body panel inspection, while important for cosmetic and minor damage assessment, typically poses less risk to occupant safety unless panels affect critical components like airbags or sensor systems. Prioritizing thorough frame inspections ensures that underlying safety concerns from impact damage are properly identified and addressed.

Choosing the Right Inspection for Your Vehicle’s Needs

Frame inspection focuses on the structural integrity of the vehicle's chassis, identifying damage such as bends, cracks, or corrosion that could compromise safety and alignment. Body panel inspection evaluates the exterior surface for dents, scratches, rust, and paint quality, ensuring aesthetic appeal and preventing further degradation. Choosing the right inspection depends on whether the vehicle requires structural safety assurance or cosmetic maintenance to maintain value and performance.

Frame inspection vs body panel inspection Infographic

cardiffo.com

cardiffo.com