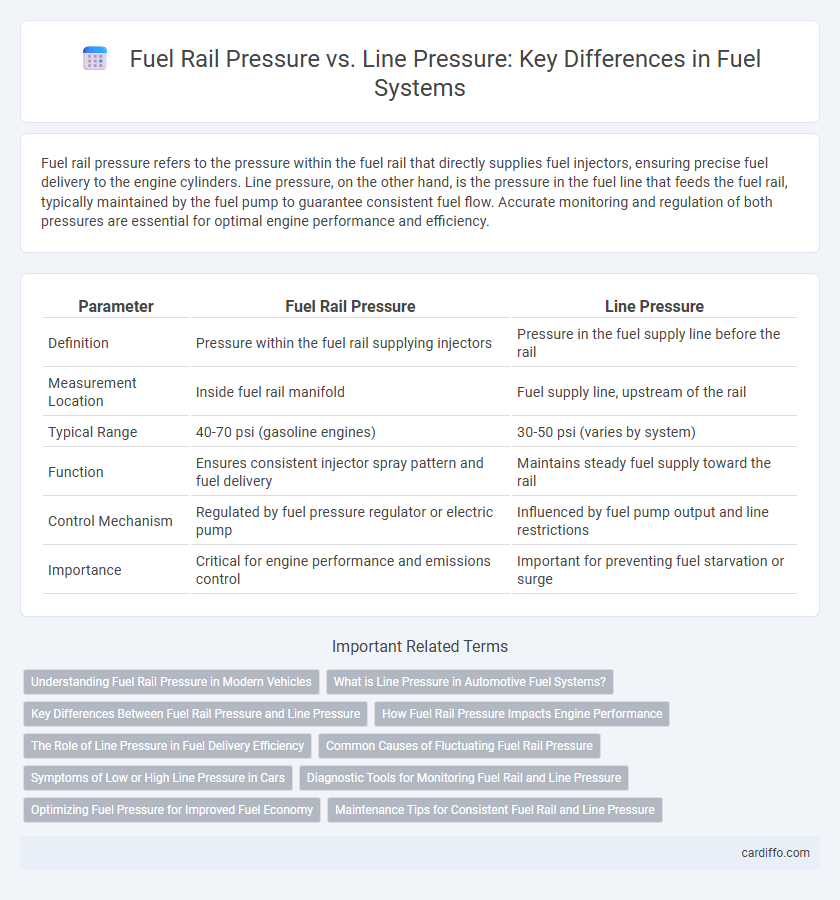

Fuel rail pressure refers to the pressure within the fuel rail that directly supplies fuel injectors, ensuring precise fuel delivery to the engine cylinders. Line pressure, on the other hand, is the pressure in the fuel line that feeds the fuel rail, typically maintained by the fuel pump to guarantee consistent fuel flow. Accurate monitoring and regulation of both pressures are essential for optimal engine performance and efficiency.

Table of Comparison

| Parameter | Fuel Rail Pressure | Line Pressure |

|---|---|---|

| Definition | Pressure within the fuel rail supplying injectors | Pressure in the fuel supply line before the rail |

| Measurement Location | Inside fuel rail manifold | Fuel supply line, upstream of the rail |

| Typical Range | 40-70 psi (gasoline engines) | 30-50 psi (varies by system) |

| Function | Ensures consistent injector spray pattern and fuel delivery | Maintains steady fuel supply toward the rail |

| Control Mechanism | Regulated by fuel pressure regulator or electric pump | Influenced by fuel pump output and line restrictions |

| Importance | Critical for engine performance and emissions control | Important for preventing fuel starvation or surge |

Understanding Fuel Rail Pressure in Modern Vehicles

Fuel rail pressure in modern vehicles is the consistent pressure maintained within the fuel rail that supplies fuel injectors, typically ranging from 40 to 60 psi in gasoline direct injection systems. Fuel rail pressure directly influences the precision of fuel atomization and combustion efficiency, thereby impacting engine performance and emissions. Unlike line pressure, which measures fuel pressure within the supply line from the fuel pump, fuel rail pressure is carefully regulated by the fuel pressure regulator to ensure optimal engine operation under varying load conditions.

What is Line Pressure in Automotive Fuel Systems?

Line pressure in automotive fuel systems refers to the consistent pressure maintained within the fuel delivery lines between the fuel pump and the fuel rail, ensuring efficient fuel flow to the engine. It is critical for preventing fuel vapor lock and maintaining proper injector operation under varying engine loads and speeds. Unlike fuel rail pressure, which is measured directly at the fuel injectors, line pressure reflects the overall system stability and delivery efficiency throughout the fuel supply path.

Key Differences Between Fuel Rail Pressure and Line Pressure

Fuel rail pressure refers to the pressure within the fuel rail that directly supplies injectors, typically measured in pounds per square inch (psi) or bar, and is critical for precise fuel atomization in modern engines. Line pressure, conversely, denotes the pressure in the fuel line from the tank to the rail, ensuring steady fuel delivery before injection, often higher and less regulated than rail pressure. The key difference lies in their roles: fuel rail pressure controls the injection precision, while line pressure maintains overall fuel flow stability throughout the system.

How Fuel Rail Pressure Impacts Engine Performance

Fuel rail pressure directly affects the amount of fuel delivered to the engine's injectors, ensuring precise combustion and optimal power output. Maintaining consistent fuel rail pressure is critical for engine efficiency, as fluctuations can lead to poor fuel atomization and increased emissions. High or unstable fuel rail pressure often results in rough idling, reduced throttle response, and decreased overall engine performance.

The Role of Line Pressure in Fuel Delivery Efficiency

Line pressure in fuel systems regulates the amount of fuel delivered to the fuel injectors, ensuring consistent fuel flow that matches engine demand. It impacts fuel delivery efficiency by maintaining optimal pressure within the fuel rail, preventing fluctuations that could lead to engine performance issues. Precise line pressure control allows for better combustion, improved fuel economy, and reduced emissions.

Common Causes of Fluctuating Fuel Rail Pressure

Fluctuating fuel rail pressure often results from a faulty fuel pressure regulator, which fails to maintain consistent pressure within the fuel rail. A clogged or failing fuel filter restricts fuel flow, causing variations in line pressure that directly impact fuel rail stability. Electrical issues with the fuel pump driver module or wiring can also disrupt fuel pump operation, leading to inconsistent fuel delivery and pressure fluctuations.

Symptoms of Low or High Line Pressure in Cars

Low fuel rail pressure in cars typically causes engine misfires, poor acceleration, and stalling due to inadequate fuel delivery to the injectors. High line pressure can lead to rough idling, excessive fuel consumption, and potential damage to fuel system components like the fuel pump and injectors. Monitoring fuel pressure accurately with a gauge helps diagnose issues related to pressure fluctuations, ensuring optimal engine performance and fuel efficiency.

Diagnostic Tools for Monitoring Fuel Rail and Line Pressure

Fuel rail pressure and line pressure are critical parameters monitored by advanced diagnostic tools such as fuel pressure sensors and electronic pressure testers to ensure optimal engine performance. Precision diagnostic equipment measures these pressures separately, enabling accurate detection of fuel delivery issues, pressure drops, or leaks within the fuel system. Real-time data from these tools assist technicians in troubleshooting fuel injection problems and maintaining efficient combustion control.

Optimizing Fuel Pressure for Improved Fuel Economy

Optimizing fuel rail pressure rather than just line pressure ensures precise fuel delivery and enhanced atomization, directly improving combustion efficiency and fuel economy. Maintaining ideal fuel rail pressure reduces excess fuel consumption and emissions by matching pressure to engine load and speed requirements. Advanced fuel management systems monitor and adjust rail pressure dynamically to maximize fuel efficiency and engine performance.

Maintenance Tips for Consistent Fuel Rail and Line Pressure

Maintaining consistent fuel rail and line pressure requires regular inspection of fuel injectors and pressure regulators to prevent clogs and leaks that can cause pressure fluctuations. Using high-quality fuel and replacing fuel filters on schedule ensures clean fuel flow, reducing strain on the fuel pump and maintaining stable pressure levels. Periodic testing with a fuel pressure gauge helps diagnose discrepancies early, allowing timely repairs and extended system longevity.

Fuel Rail Pressure vs Line Pressure Infographic

cardiffo.com

cardiffo.com