Manual refueling requires human intervention to operate fuel pumps, which can increase the risk of errors and safety hazards. Automated refueling systems use advanced sensors and software to precisely control fuel delivery, enhancing efficiency and reducing spillage. This technology also enables better fuel management tracking and minimizes downtime for vehicles or machinery.

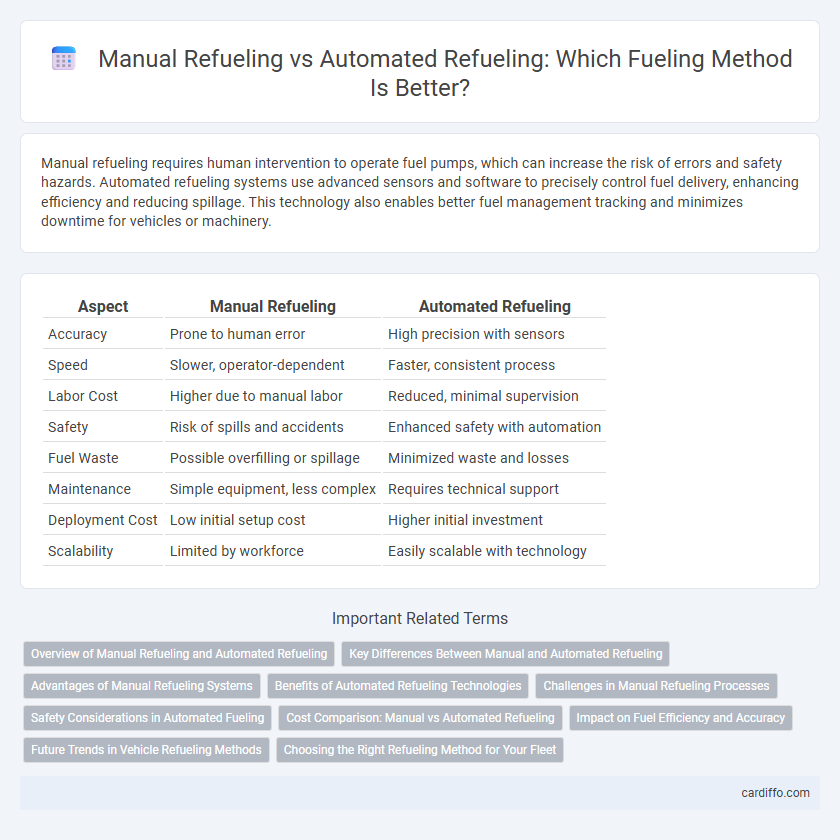

Table of Comparison

| Aspect | Manual Refueling | Automated Refueling |

|---|---|---|

| Accuracy | Prone to human error | High precision with sensors |

| Speed | Slower, operator-dependent | Faster, consistent process |

| Labor Cost | Higher due to manual labor | Reduced, minimal supervision |

| Safety | Risk of spills and accidents | Enhanced safety with automation |

| Fuel Waste | Possible overfilling or spillage | Minimized waste and losses |

| Maintenance | Simple equipment, less complex | Requires technical support |

| Deployment Cost | Low initial setup cost | Higher initial investment |

| Scalability | Limited by workforce | Easily scalable with technology |

Overview of Manual Refueling and Automated Refueling

Manual refueling involves the physical handling of fuel containers and direct transfer of fuel by an operator, often used in smaller scale or remote applications. Automated refueling systems utilize robotic arms and sensors to precisely deliver fuel without human intervention, increasing speed and safety. These automated solutions reduce spillage risks and improve operational efficiency in large-scale fuel management operations.

Key Differences Between Manual and Automated Refueling

Manual refueling requires human intervention to operate fueling equipment, increasing the risk of errors and safety hazards, while automated refueling uses technology such as robotic arms and sensors to enhance precision and reduce risks. Automated systems improve efficiency by minimizing fuel spillage and optimizing fuel flow rates, leading to faster turnaround times compared to manual methods. Furthermore, automation enables better data tracking for fuel consumption and maintenance, supporting improved operational insights and cost savings.

Advantages of Manual Refueling Systems

Manual refueling systems offer unparalleled control and precision, allowing operators to closely monitor fuel flow and prevent overfilling or spills. These systems require minimal technological investment, making them cost-effective and easier to maintain in remote or low-traffic locations. The simplicity of manual refueling equipment reduces the risk of mechanical failure, ensuring reliable operation even in challenging environments.

Benefits of Automated Refueling Technologies

Automated refueling technologies enhance safety by reducing human exposure to hazardous fuel vapors and minimizing spill risks. These systems improve efficiency through faster, precise fuel delivery, lowering downtime and operational costs. Integration with digital monitoring platforms enables real-time data tracking, optimizing fuel management and maintenance scheduling.

Challenges in Manual Refueling Processes

Manual refueling processes face significant challenges such as inconsistent fuel measurement, increased risk of spills, and human error leading to inaccurate fuel dispensing. These issues result in operational inefficiencies, safety hazards, and higher environmental impact due to potential fuel leakage. Limited traceability and prolonged service times further complicate fuel management and accountability during manual refueling operations.

Safety Considerations in Automated Fueling

Automated refueling systems significantly reduce the risk of human error, minimizing fuel spills and exposure to hazardous fumes compared to manual refueling. Advanced sensors and real-time monitoring technologies in automated fueling enhance safety by detecting leaks and preventing overfilling. These systems comply with stringent safety standards, ensuring a secure fueling process in industrial and commercial environments.

Cost Comparison: Manual vs Automated Refueling

Manual refueling incurs higher labor costs due to the need for consistent human intervention, while automated refueling systems require substantial upfront investment but significantly lower ongoing operational expenses. Automated refueling reduces fuel waste and improves accuracy, leading to cost savings over time compared to manual methods prone to errors and inefficiencies. Maintenance and upgrade expenses for automated systems are offset by enhanced productivity and minimized workforce requirements, resulting in a more cost-effective fueling process.

Impact on Fuel Efficiency and Accuracy

Manual refueling often results in inconsistent fuel volume measurements and can lead to fuel wastage or under-fueling, negatively impacting overall fuel efficiency. Automated refueling systems utilize precise sensors and real-time data analytics to ensure accurate fuel dispensation, significantly reducing errors and optimizing fuel consumption. Implementing automated refueling enhances monitoring capabilities, leading to improved accuracy in fuel management and long-term cost savings.

Future Trends in Vehicle Refueling Methods

Manual refueling requires human intervention to operate pumps, while automated refueling systems utilize robotics and sensors to deliver fuel efficiently without direct contact. Future trends in vehicle refueling emphasize contactless technology, integration with electric and hydrogen fuel stations, and AI-driven optimization for faster, safer, and more sustainable refueling processes. Innovations like autonomous fuel delivery drones and smart fueling stations are set to transform the refueling landscape, enhancing convenience and reducing environmental impact.

Choosing the Right Refueling Method for Your Fleet

Manual refueling offers greater control and flexibility, making it ideal for smaller fleets or locations with limited infrastructure. Automated refueling systems enhance efficiency, reduce human error, and improve safety, benefiting larger fleets aiming to minimize downtime and operational costs. Evaluating fleet size, budget, and operational priorities is essential to select the optimal refueling method that maximizes productivity and cost-effectiveness.

Manual Refueling vs Automated Refueling Infographic

cardiffo.com

cardiffo.com