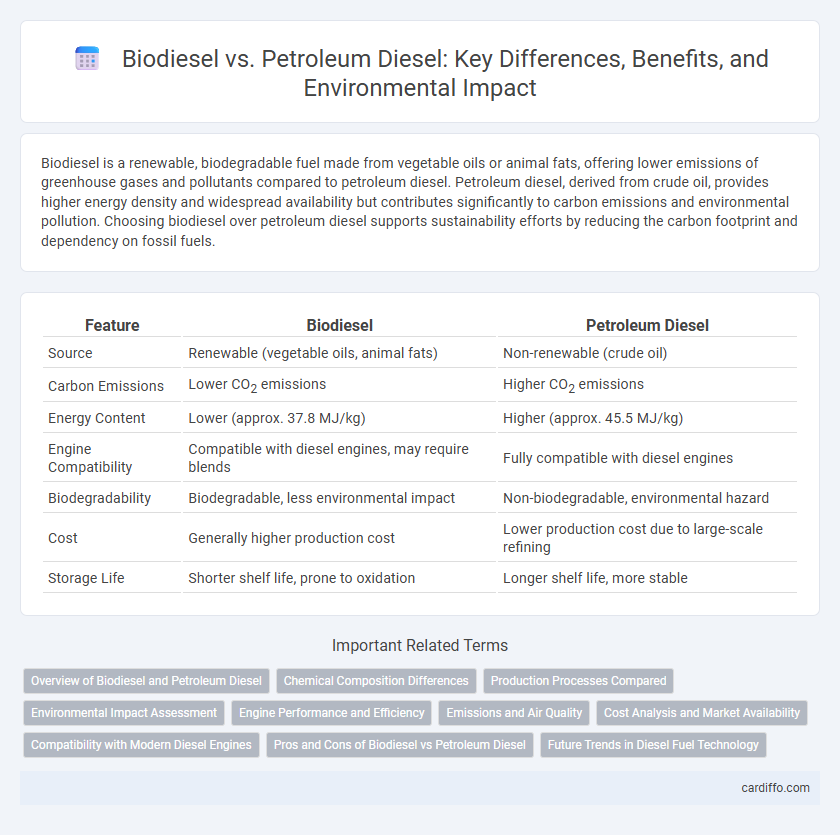

Biodiesel is a renewable, biodegradable fuel made from vegetable oils or animal fats, offering lower emissions of greenhouse gases and pollutants compared to petroleum diesel. Petroleum diesel, derived from crude oil, provides higher energy density and widespread availability but contributes significantly to carbon emissions and environmental pollution. Choosing biodiesel over petroleum diesel supports sustainability efforts by reducing the carbon footprint and dependency on fossil fuels.

Table of Comparison

| Feature | Biodiesel | Petroleum Diesel |

|---|---|---|

| Source | Renewable (vegetable oils, animal fats) | Non-renewable (crude oil) |

| Carbon Emissions | Lower CO2 emissions | Higher CO2 emissions |

| Energy Content | Lower (approx. 37.8 MJ/kg) | Higher (approx. 45.5 MJ/kg) |

| Engine Compatibility | Compatible with diesel engines, may require blends | Fully compatible with diesel engines |

| Biodegradability | Biodegradable, less environmental impact | Non-biodegradable, environmental hazard |

| Cost | Generally higher production cost | Lower production cost due to large-scale refining |

| Storage Life | Shorter shelf life, prone to oxidation | Longer shelf life, more stable |

Overview of Biodiesel and Petroleum Diesel

Biodiesel is a renewable, biodegradable fuel derived from vegetable oils or animal fats, offering lower emissions of carbon monoxide and particulates compared to petroleum diesel. Petroleum diesel, a fossil fuel refined from crude oil, delivers higher energy density and widespread engine compatibility but produces more greenhouse gases and pollutants. Both fuels serve as alternatives for diesel engines, with biodiesel promoting sustainability and petroleum diesel providing established performance and infrastructure.

Chemical Composition Differences

Biodiesel consists primarily of fatty acid methyl esters (FAME) derived from vegetable oils or animal fats, contrasting with petroleum diesel, which is a complex mixture of hydrocarbons ranging from C10 to C20 chains. The oxygen content in biodiesel molecules improves combustion efficiency and reduces emissions compared to the hydrocarbon-only structure of petroleum diesel. Chemical properties such as higher cetane numbers and intrinsic lubricity in biodiesel enhance engine performance, while petroleum diesel's sulfur content contributes to pollutant formation during combustion.

Production Processes Compared

Biodiesel production primarily involves transesterification, where vegetable oils or animal fats react with an alcohol like methanol in the presence of a catalyst to form fatty acid methyl esters. Petroleum diesel is refined from crude oil through fractional distillation and further treated by hydrocracking and catalytic reforming to improve fuel quality. Biodiesel processes offer renewable feedstocks and lower emissions, whereas petroleum diesel relies on finite fossil reserves and complex refining techniques.

Environmental Impact Assessment

Biodiesel significantly reduces greenhouse gas emissions by up to 86% compared to petroleum diesel, contributing to lower carbon footprints and decreased air pollution. It is biodegradable and produces fewer toxic emissions, including particulate matter and sulfur oxides, which improves overall air quality. Lifecycle analyses highlight that biodiesel's renewable sourcing leads to more sustainable fuel consumption, minimizing environmental degradation associated with fossil fuel extraction and use.

Engine Performance and Efficiency

Biodiesel exhibits higher cetane numbers than petroleum diesel, enhancing combustion efficiency and resulting in smoother engine performance with reduced ignition delay. Engine power output with biodiesel is typically comparable to petroleum diesel, though slightly lower energy content may cause a minor decrease in fuel economy. Biodiesel's superior lubricity reduces engine wear, extending component lifespan and improving overall operational efficiency.

Emissions and Air Quality

Biodiesel significantly reduces emissions of carbon monoxide, particulate matter, and unburned hydrocarbons compared to petroleum diesel, enhancing overall air quality. It produces lower levels of sulfur oxides and greenhouse gases, contributing to reduced smog formation and improved respiratory health. The combustion of biodiesel also emits fewer carcinogenic compounds, making it a cleaner alternative for urban environments.

Cost Analysis and Market Availability

Biodiesel typically costs 20-50% more per gallon than petroleum diesel due to higher production expenses and limited economies of scale. Petroleum diesel dominates global markets with extensive refining infrastructure and widespread distribution networks, making it more readily available than biodiesel. Market availability of biodiesel remains concentrated in regions with supportive policies and renewable fuel standards, impacting its cost competitiveness and adoption rates.

Compatibility with Modern Diesel Engines

Biodiesel blends up to B20 are widely compatible with modern diesel engines without requiring significant modifications, offering cleaner combustion and reduced emissions. Petroleum diesel remains the industry standard due to its higher energy density and extensive fueling infrastructure, ensuring optimal engine performance and range. Engine manufacturers increasingly endorse low-level biodiesel blends, facilitating a gradual shift towards sustainable fuels while maintaining reliability.

Pros and Cons of Biodiesel vs Petroleum Diesel

Biodiesel offers significant environmental benefits, producing fewer greenhouse gas emissions and being biodegradable compared to petroleum diesel, which relies on finite fossil fuel resources and emits higher levels of pollutants. However, biodiesel can have lower energy content and may cause issues with cold weather performance and engine compatibility, whereas petroleum diesel typically provides higher energy density and wider availability. Cost and infrastructure challenges remain for biodiesel adoption, while petroleum diesel benefits from established distribution networks and consistent engine performance.

Future Trends in Diesel Fuel Technology

Biodiesel and petroleum diesel are advancing with a strong focus on sustainability and efficiency, driven by regulatory pressures and environmental concerns. Innovations in biodiesel include enhanced feedstock diversity and next-generation biofuels that reduce carbon emissions and improve engine compatibility. Petroleum diesel technology is evolving through cleaner refining processes and the integration of renewable diesel blends to lower sulfur content and enhance fuel performance.

Biodiesel vs Petroleum Diesel Infographic

cardiffo.com

cardiffo.com